Preparation method and using method for polyamino/amidoxim-modified multifunctional ion exchange fibers

An ion-exchange fiber and amidoxime-based technology, applied in the field of wastewater treatment, can solve problems such as easy scaling, poor removal effect, and limited adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

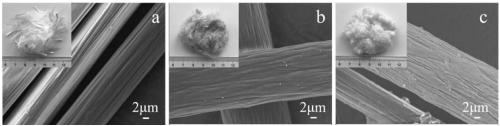

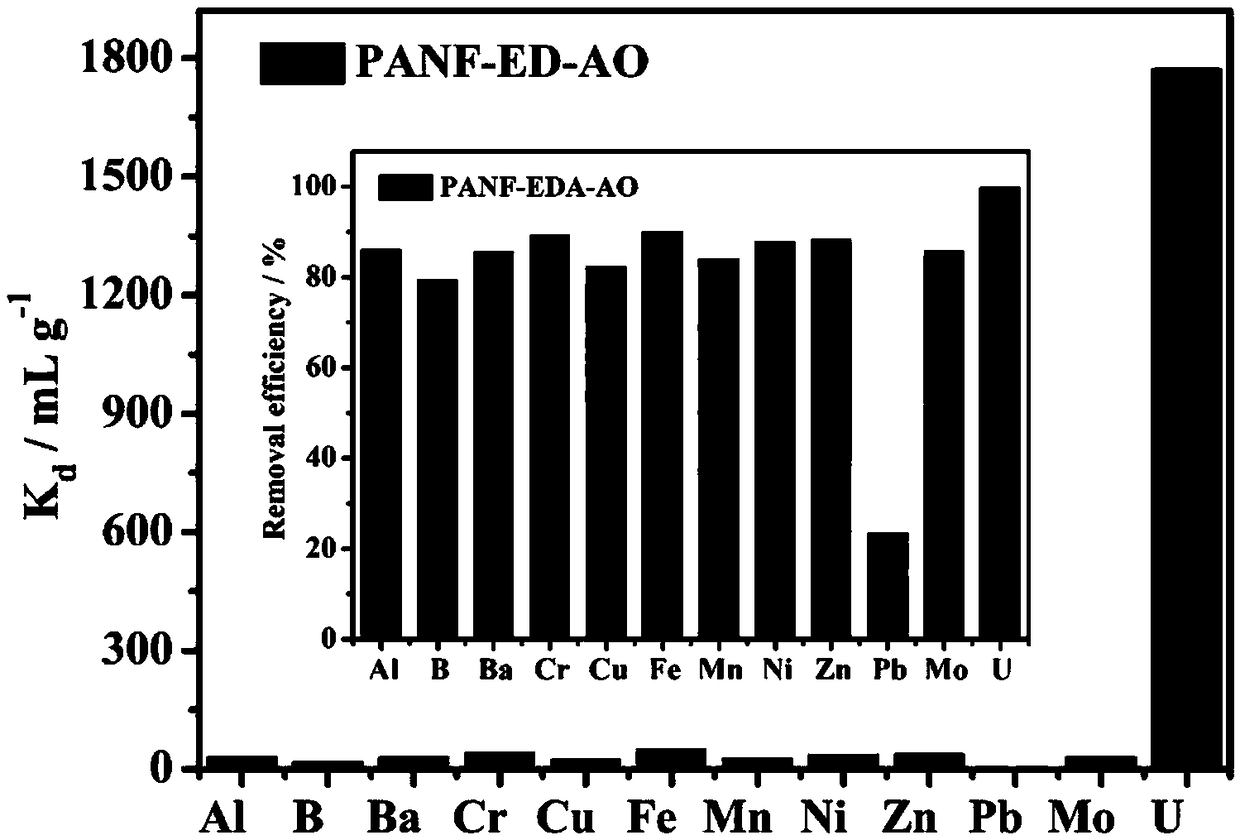

Image

Examples

Embodiment 1

[0023] Mixed solution 1 was prepared according to the volume ratio of aminating agent, swelling agent, and deionized water at 4:1:1, and the molar ratio of the nitrile group in the polyacrylonitrile fiber to the aminating agent was 4:1 to mixed solution 1. Add polyacrylonitrile fibers to the mixture, react with hydrothermal reaction at 110°C for 3 hours, wash with deionized water, and then dry at 60°C for 12 hours to prepare polyamine-modified ion-exchange fibers. The polyamine-based grafting rate It is 34.3%; wherein, the amination reagent is ethylenediamine, and the swelling agent is ethylene glycol; the volume ratio of swelling agent to deionized water is 4:1, and the mass concentration of hydroxylamine hydrochloride is 2.0g / L. Mix solution 2, use a pH regulator to control the pH of solution 2 at 7.0, and weigh the polyamine-based ion-exchange fiber according to the solid-to-liquid ratio of the polyamine-based ion-exchange fiber to the mixed solution 2 of 5.0g: 1L, and add t...

Embodiment 2

[0024] Example 2: Mixed solution 1 was prepared according to the volume ratio of amination reagent, swelling agent and deionized water as 3:2:1, and the molar ratio of the nitrile group in the polyacrylonitrile fiber to the amination reagent was 3:1 Add polyacrylonitrile fibers to the mixed solution 1, react with water heat at 100°C for 5 hours, wash with deionized water, and then dry at 70°C for 12 hours to prepare polyamine-modified ion-exchange fibers. The radical grafting rate is 28.4%; among them, the amination agent is acrylamide, and the swelling agent is methylene disulfone; according to the volume ratio of swelling agent to deionized water is 2:1, the mass concentration of hydroxylamine hydrochloride is 3.0g / L Mixed solution 2 was prepared with a pH regulator to control the pH of solution 2 at 6.5, and the polyamine-based ion exchange fiber was weighed according to the solid-liquid ratio of the polyamine-based ion-exchange fiber to the mixed solution 2. 3.0g: 1L Fiber...

Embodiment 3

[0025] Example 3: Mixed solution 1 was prepared according to the volume ratio of amination reagent, swelling agent and deionized water as 2:2:1, and the molar ratio of the nitrile group in the polyacrylonitrile fiber to the amination reagent was 5:1 Add polyacrylonitrile fibers to the mixed solution 1, and conduct a hydrothermal reaction at 120°C for 4 hours, wash with deionized water, and then dry at 80°C for 6 hours to prepare polyamine-modified ion-exchange fibers. The radical grafting rate is 51.6%; among them, the amination agent is acrylamide, and the swelling agent is methylene disulfone; according to the volume ratio of swelling agent and deionized water is 5:1, the mass concentration of hydroxylamine hydrochloride is 5.0g / L Mixed solution 2 was prepared with a pH regulator to control the pH of solution 2 at 7.5, and the polyamine-based ion exchange fiber was weighed according to the solid-liquid ratio of the polyamine-based ion-exchange fiber to the mixed solution 2. 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com