Ru/MgO catalyst and preparation method and application thereof

A catalyst, the technology of ruthenium tetrachloride, which is applied in the field of Ru/MgO catalyst and its preparation, can solve the problems of inability to achieve the catalytic effect of noble metals, poor binding force between active components and carriers, and difficult recovery, so as to avoid catalyst deactivation effect, Good catalytic stability and superior catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

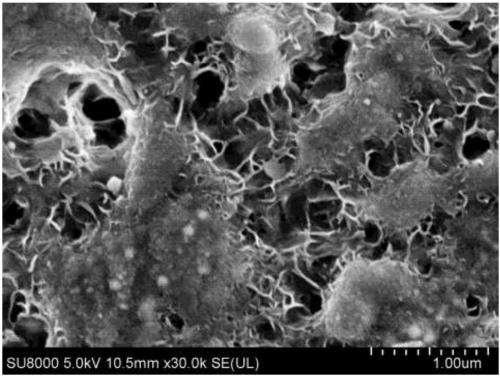

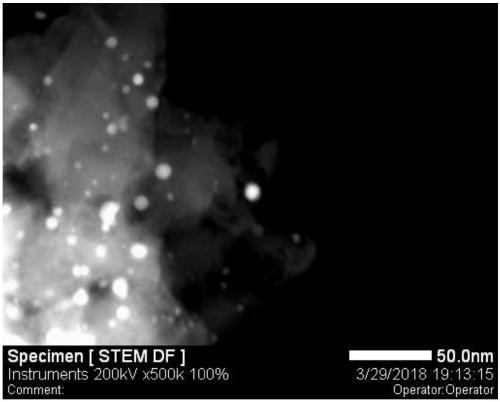

[0030] A preparation method for Ru / MgO used to produce hydrogen by hydrolysis of sodium borohydride, mainly comprising the following steps:

[0031] ①Cut metal magnesium into pieces with a size of 2mm*20mm*40mm, polish and polish with 600#, 3000# in turn, and ultrasonically clean in ethanol for 30 minutes, dry and store;

[0032] ② Dilute the concentrated hydrochloric acid to form 0.012mol / L dilute hydrochloric acid; dissolve 1g of ruthenium trichloride in 1.2ml of dilute hydrochloric acid solution, and set the volume to 20ml to form a ruthenium tetrachloride solution with a concentration of 0.24mol / L ;

[0033] ③ Configure the electrolyte, add sodium silicate, potassium fluoride, and potassium hydroxide to 500ml of water and dissolve; the concentrations are sodium silicate 10g / ml, potassium fluoride 6g / ml, and potassium hydroxide 5g / ml;

[0034] ④ Add 5ml of the ruthenium tetrachloride solution prepared in step ② into the electrolyte obtained in step ③, and mix evenly. The f...

Embodiment 2

[0045] A preparation method for Ru / MgO used to produce hydrogen by hydrolysis of sodium borohydride, mainly comprising the following steps:

[0046] ① Weave magnesium wire with a diameter of 500 μm and a length of 1 m into a metal geometry with a honeycomb structure, ultrasonically clean it in ethanol for 30 minutes, and dry it in an oven;

[0047] ② Dilute the concentrated hydrochloric acid and configure it into 0.024mol / L dilute hydrochloric acid; dissolve 1g of ruthenium trichloride in 1.2ml of dilute hydrochloric acid solution, and set the volume to 20ml, and finally form a ruthenium tetrachloride solution with a concentration of 0.24mol / L L;

[0048] ③ Configure the electrolyte, add sodium silicate, potassium fluoride, and potassium hydroxide to 500ml of water and dissolve; the concentrations are sodium silicate 15g / ml, potassium fluoride 8g / ml, and potassium hydroxide 8g / ml;

[0049] ④ Add 10ml of the configured ruthenium tetrachloride solution into the electrolyte, mix...

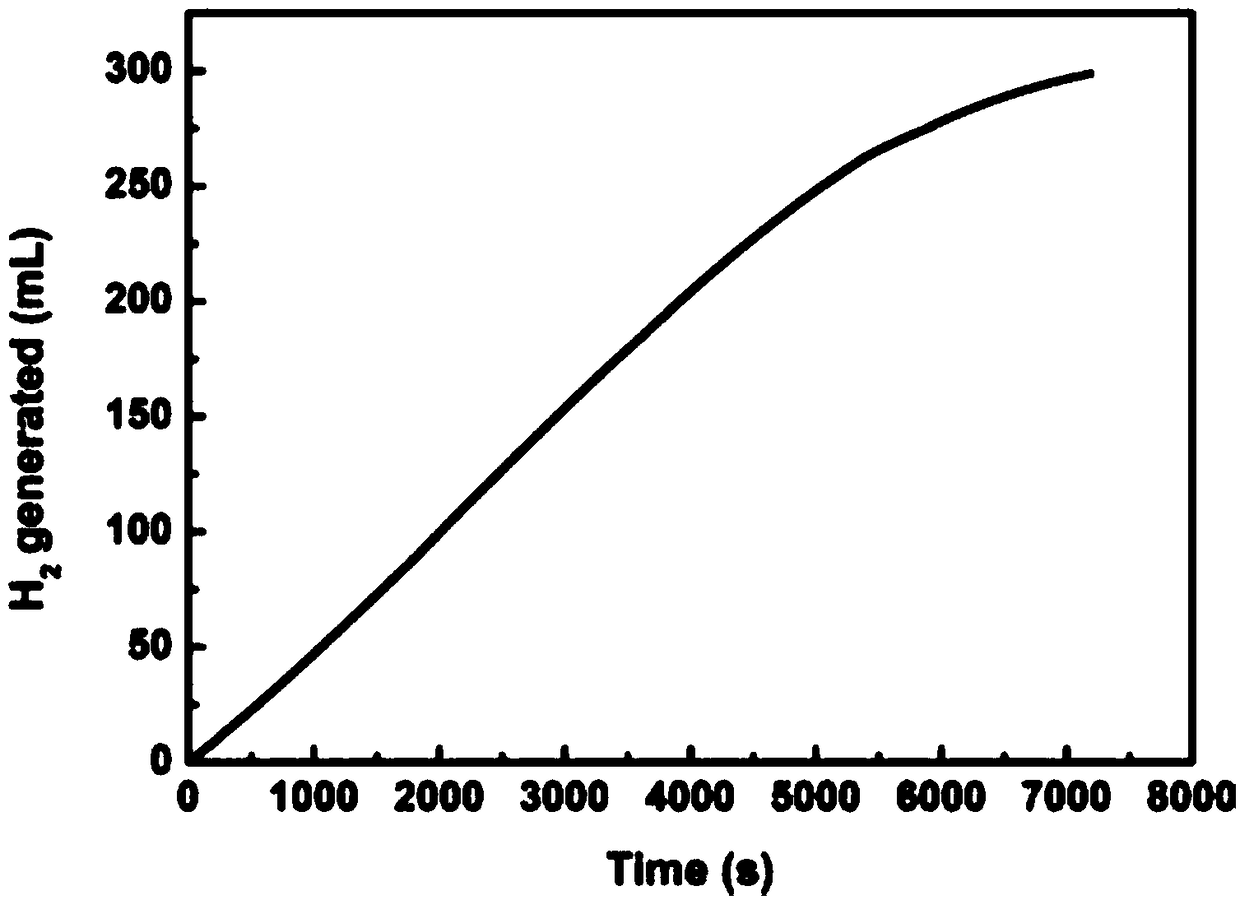

Embodiment 3

[0055] A Ru / MgO catalyst for hydrogen production by hydrolysis of sodium borohydride and a preparation method thereof, mainly comprising the following steps:

[0056] ①Take a metal magnesium sheet with a size of 2mm*20mm*40mm, and evenly distribute small holes with a diameter of 1mm on the magnesium sheet. After ultrasonic cleaning in ethanol for 30 minutes, dry and store in an oven;

[0057] ② Dilute the concentrated hydrochloric acid to make 0.04mol / L dilute hydrochloric acid; dissolve 1g of ruthenium trichloride in 1.2ml of dilute hydrochloric acid solution, and set the volume to 20ml, the final concentration of ruthenium tetrachloride solution is 0.24mol / L ;

[0058] ③ Configure the electrolyte, add sodium silicate, potassium fluoride, and potassium hydroxide to 500ml of water and dissolve; the concentrations are sodium silicate 25g / ml, potassium fluoride 10g / ml, and potassium hydroxide 10g / ml;

[0059] ④ Add 15ml of the configured ruthenium chloride solution into the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com