High-quality elastic putty for building external walls and method for preparing high-quality elastic putty

An elastic putty, building exterior wall technology, applied in the direction of climate sustainability, sustainable manufacturing/processing, filling slurry, etc., can solve problems such as endangering the normal living of residents, volume expansion of putty, no elastic elasticity, etc., and achieve enhanced thermal insulation. Insulation effect, improvement of thermal insulation performance, effect of high elastic expansion and contraction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

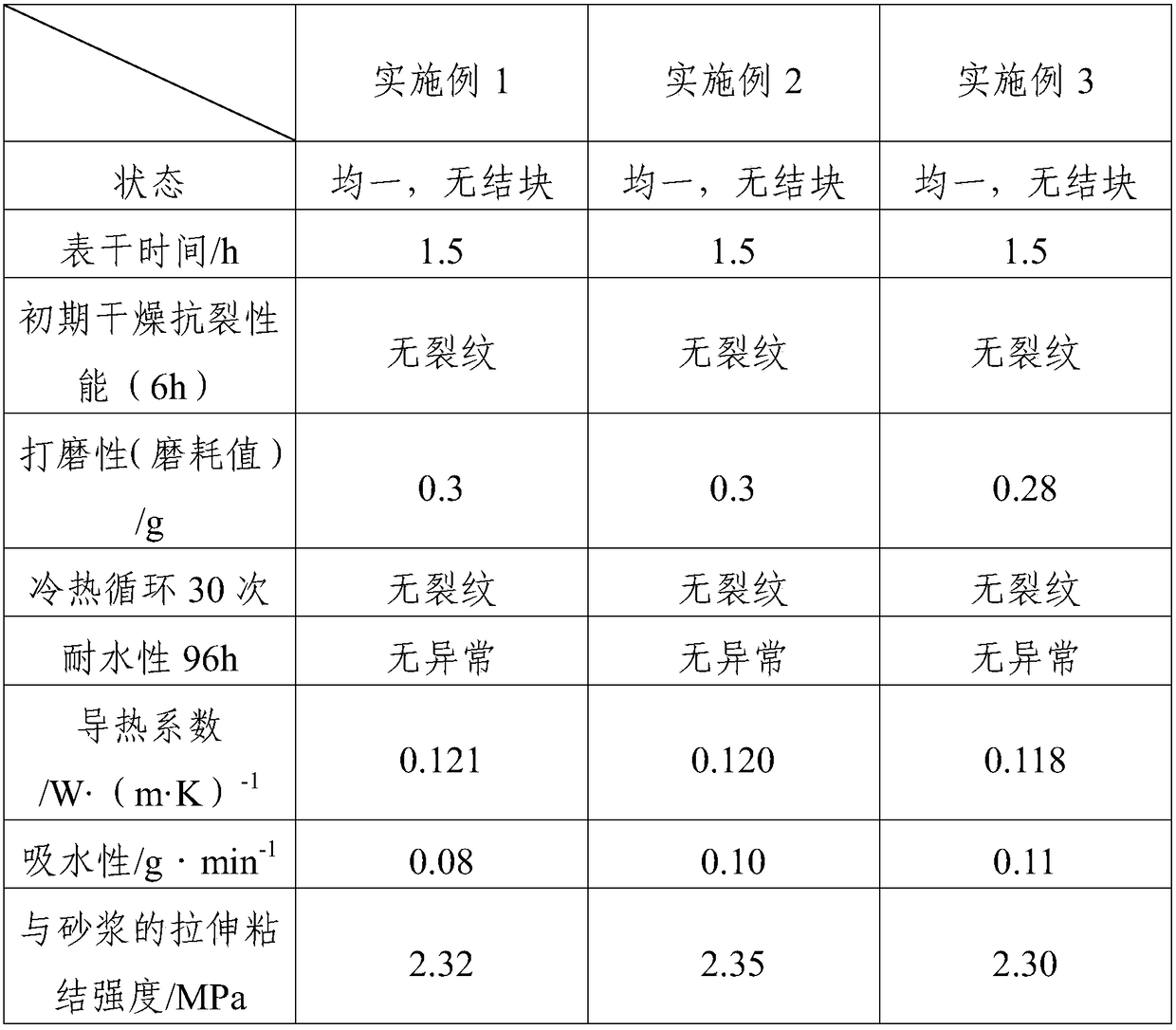

Embodiment 1

[0028] A high-quality elastic putty for building exterior walls, comprising the following components in parts by weight: fluorine-containing styrene-acrylic emulsion, acrylic elastic emulsion mixed in a mass ratio of 5:1, 38 parts of elastic emulsion, modified diatomaceous earth / 10 parts of microcrystalline paraffin shaped phase change materials, 16 parts of talc, 0.2 parts of hydroxypropyl methylcellulose, 0.3 parts of alcohol esters, 2 parts of propylene glycol, 5 parts of polyvinyl alcohol, 13 parts of fly ash bleaching beads, 1 part of modified guar gum, 0.1 part of dispersant NNO, 0.2 part of silicone defoamer, 0.3 part of chitosan-based copper complex, and 16 parts of water.

[0029] The preparation method of modified diatomaceous earth / microcrystalline paraffin shaped phase change material is as follows:

[0030] Heat the microcrystalline paraffin wax to completely melt, add modified diatomaceous earth, shake with a shaker at a frequency of 140 times / min for 4 hours to obta...

Embodiment 2

[0038] A high-quality elastic putty for building exterior walls, comprising the following components in parts by weight: 40 parts of elastic emulsion mixed with fluorine-containing styrene-acrylic emulsion and acrylic elastic emulsion in a mass ratio of 1:1, and modified diatomaceous earth / 10 parts of microcrystalline paraffin shaped phase change material, 18 parts of talc, 0.2 parts of hydroxypropyl methylcellulose, 0.1 parts of alcohol esters, 3 parts of propylene glycol, 3 parts of polyvinyl alcohol, 10 parts of fly ash bleaching beads, 4 parts of modified guar gum, 0.1 part of dispersant NNO, 0.2 part of silicone defoamer, 0.2 part of chitosan-based manganese complex, and 20 parts of water.

[0039] The preparation method of modified diatomite / microcrystalline paraffin shape-setting phase change material is as follows:

[0040] Heat the microcrystalline paraffin wax to completely melt, add modified diatomaceous earth, shake with a shaker at a frequency of 150 times / min for 4 h...

Embodiment 3

[0048] A high-quality elastic putty for building exterior walls, comprising the following components in parts by weight: 35 parts of elastic emulsion mixed with fluorine-containing styrene-acrylic emulsion and acrylic elastic emulsion in a mass ratio of 2:1, and modified diatomaceous earth / 12 parts of microcrystalline paraffin shaped phase change materials, 16 parts of talc, 0.4 parts of hydroxypropyl methylcellulose, 0.1 parts of alcohol esters, 1 part of propylene glycol, 2 parts of polyvinyl alcohol, 12 parts of fly ash bleaching beads, 2 parts of modified guar gum, 0.1 part of dispersant NNO, 0.1 part of silicone defoamer, 0.3 part of chitosan-based palladium complex, and 20 parts of water.

[0049] The preparation method of modified diatomite / microcrystalline paraffin shape-setting phase change material is as follows:

[0050] Heat the microcrystalline paraffin to completely melt, add modified diatomaceous earth, shake with a shaker at a frequency of 150 times / min for 4 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com