Preparation method for iron-loading mesoporous carbon material, as well as product and application thereof

A technology of mesoporous carbon and polyethylene oxide, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems that ordered mesoporous carbon materials are not easy to separate, and achieve good Magnetic properties, uniform pore size distribution, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

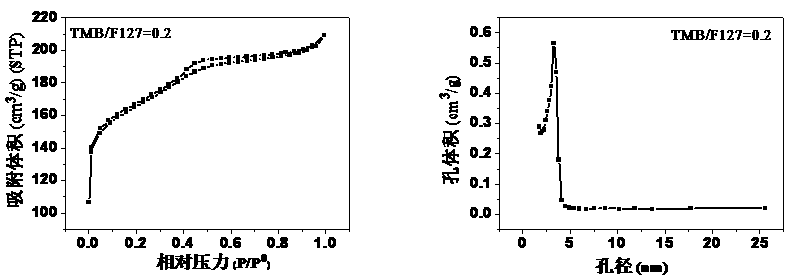

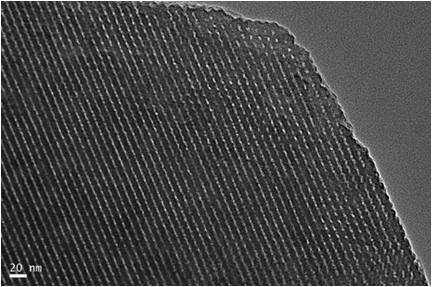

[0036] A method for preparing iron-loaded mesoporous carbon materials, using polyoxyethylene-polyphenylene ether-polyoxyethylene triblock copolymer PEO-PPO-PEO (F127) as a template without adding alkali, adding 1,3,5-trimethylbenzene, resorcinol, and hexamethylenetetramine synthesize ordered mesoporous polymer intermediates, and then add ferric citrate to prepare iron-loaded ordered mesoporous carbon materials, which are prepared according to the following steps:

[0037] a. Weigh 1.0g of F127 and dissolve it in 18g of water, add 0.2g of 1,3,5-trimethylbenzene (TMB), 0.55g

[0038] Resorcinol and 0.35 g of hexamethylenetetramine were stirred at room temperature for 2 h to obtain a clear solution.

[0039] b. Transfer the solution of a into a 100 ml reaction kettle, and conduct a hydrothermal reaction at 100ºC for 12 h.

[0040] c. Suction filter the reaction product of b, wash, and dry at 85ºC to obtain an orange polymer

[0041] intermediate.

[0042] d. Immerse the orange...

Embodiment 2

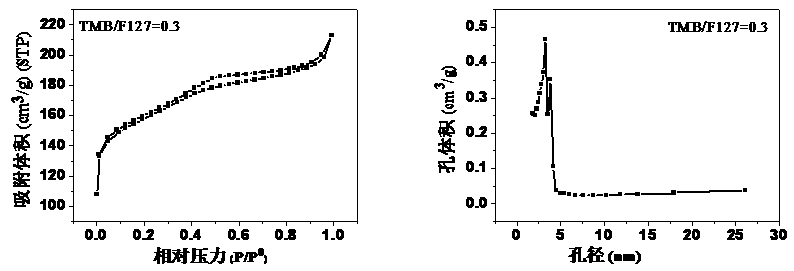

[0046] a. Weigh 1.0g of F127 and dissolve it in 18g of water, add 0.3g of 1,3,5-trimethylbenzene (TMB), 0.55g

[0047] Resorcinol and 0.35 g of hexamethylenetetramine were stirred at room temperature for 2 h to obtain a clear solution.

[0048] b. Transfer the solution of a into a 100 ml reaction kettle, and conduct a hydrothermal reaction at 100ºC for 12 hours.

[0049] c. Suction filter the reaction product of b, wash, and dry at 85ºC to obtain an orange polymer

[0050] intermediate.

[0051] d. Immerse the orange polymer synthesized in c in the dissolved ferric citrate solution. After stirring overnight, the dried product was calcined at 650ºC for 3 h under the protection of nitrogen to obtain iron-loaded ordered mesoporous carbon material.

[0052] The iron-doped ordered mesoporous carbon prepared by this method has a good mesoporous structure, and the mesoporous parameters are shown in Table 1: the specific surface area is 505m 2 / g, the pore size is 3.2nm.

[0053] T...

Embodiment 3

[0055] a. Weigh 1.0g of F127 and dissolve it in 18g of water, add 0.4g of 1,3,5-trimethylbenzene (TMB), 0.55g

[0056] Resorcinol and 0.35 g of hexamethylenetetramine were stirred at room temperature for 2 h to obtain a clear solution.

[0057] b. Transfer the solution of a into a 100 ml reaction kettle, and conduct a hydrothermal reaction at 100ºC for 12 hours.

[0058] c. Suction filter the reaction product of b, wash, and dry at 85ºC to obtain an orange polymer

[0059] intermediate.

[0060] d. Immerse the orange polymer synthesized in c in the dissolved ferric citrate solution. After stirring overnight, the dried product was calcined at 650ºC for 3 h under the protection of nitrogen to obtain iron-loaded ordered mesoporous carbon material.

[0061] The iron-doped ordered mesoporous carbon prepared by this method has a good mesoporous structure, and the mesoporous parameters are shown in Table 1: the specific surface area is 503m 2 / g, the pore size is 3.0nm.

[0062]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com