Excimer broadband pumped alkali metal blue laser

An alkali metal and excimer technology, applied in the field of alkali metal laser, can solve the problem of blue laser power bottleneck and other problems, and achieve the effect of good magnification, good magnification, and good calibration amplification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

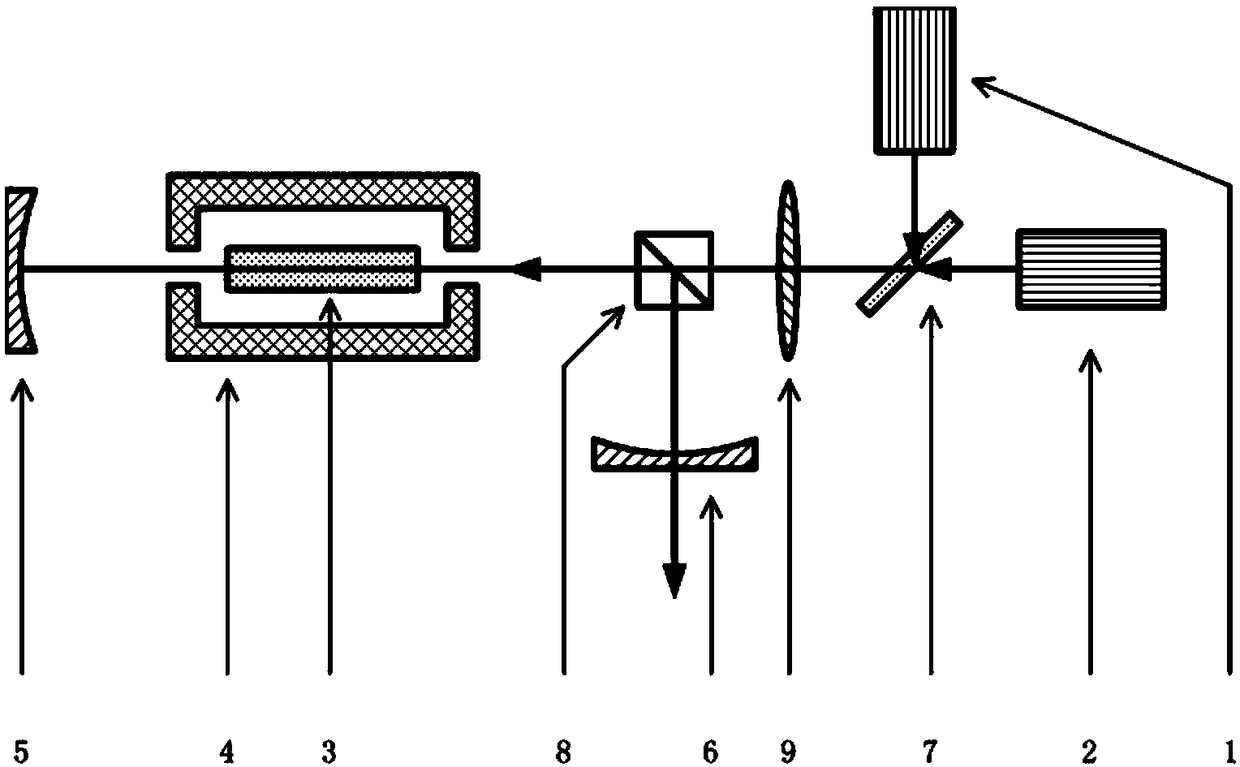

[0025] see attached figure 1 As shown, the main structure of the present invention includes: a pumping source a 1, a pumping source b 2, an alkali metal vapor pool 3, a heating furnace 4, a high reflection mirror 5, an output coupling mirror 6, a two-way Color mirror 7, a polarization beam splitting cube 8, a focusing lens 9.

specific Embodiment approach

[0027] The pump source a 1 outputs a P-polarized narrow-linewidth laser with a wavelength of D corresponding to cesium metal 2 line 852nm, the pump source b 2 outputs P-polarized wide-linewidth laser light with a wavelength of 925nm, which is transmitted through the dichroic mirror 7 and is collinear with the output laser light of the pump source a 1 reflected by the dichroic mirror 7, Two beams of P-polarized pumping lasers are focused to the center of the alkali metal vapor pool 3 by the focusing lens 9, and transmit through the polarization beam splitting cube 8 and enter the alkali metal vapor pool 3 from the end face for pumping; the alkali metal vapor pool 3 is filled with enough amount of cesium metal, while the alkali metal vapor pool 3 is also filled with helium as a buffer gas, the inflation pressure at normal temperature is 2000torr, the alkali metal vapor pool 3 is heated to 300°C by the heating furnace 4, the cesium vapor at this temperature The air pressure is 2....

Embodiment 2

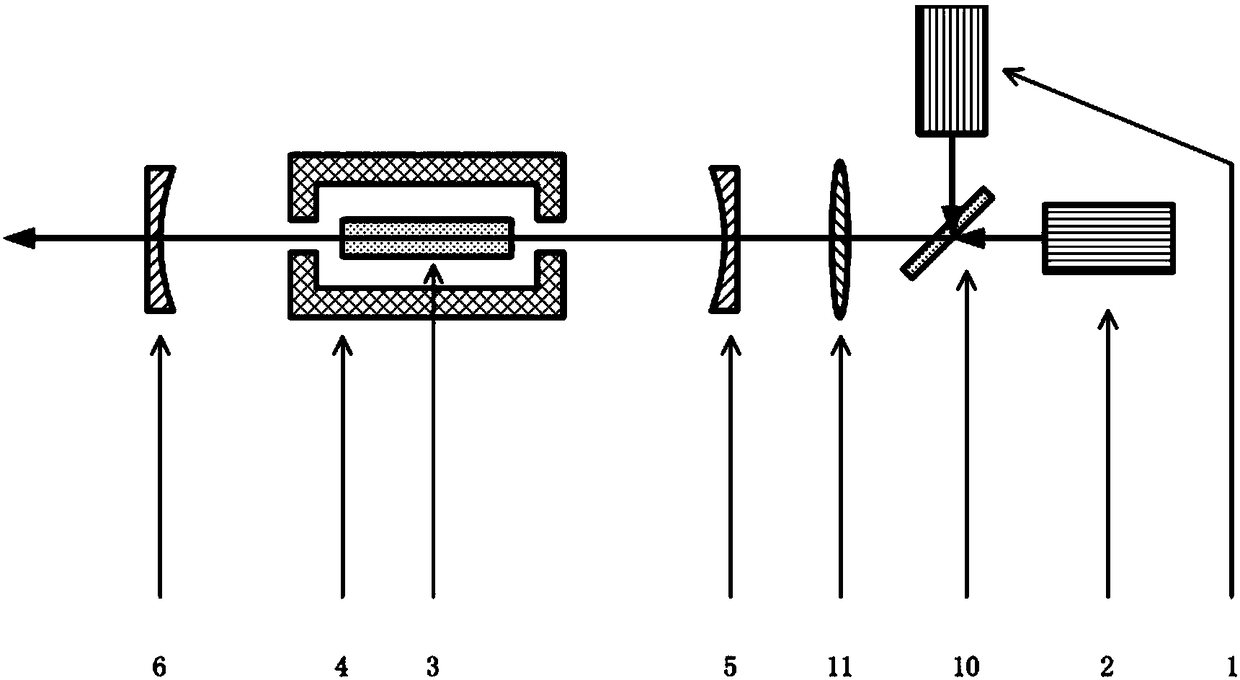

[0030] see attached figure 2 As shown, the main structure of the present invention includes: a pumping source a 1, a pumping source b 2, an alkali metal vapor pool 3, a heating furnace 4, a high reflection mirror 5, an output coupling mirror 6, a two-way Color mirror 10, a focusing lens 11.

[0031] The specific implementation method is:

[0032] The pump source a 1 outputs a narrow linewidth laser with a wavelength of D corresponding to cesium metal 2 Line 852nm, the wide-linewidth laser output by pump source b2, with a wavelength of 920nm, is transmitted through dichroic mirror 10, and is collinear with the output laser light of pump source a1 reflected by dichroic mirror 10, two beams The pumping laser light is focused to the center of the alkali metal vapor pool 3 by the focusing lens 11, and is transmitted through the high reflection mirror 5 and enters the alkali metal vapor pool 3 from the end face for pumping; the alkali metal vapor pool 3 is filled with a sufficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com