Solid hazardous waste treating system

A hazardous waste and treatment system technology, applied in the field of waste treatment devices, can solve problems such as low heat utilization efficiency, threats to groundwater, rivers, lakes and seas, and imperfect tail gas treatment, so as to improve carbonization efficiency and avoid incomplete carbonization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

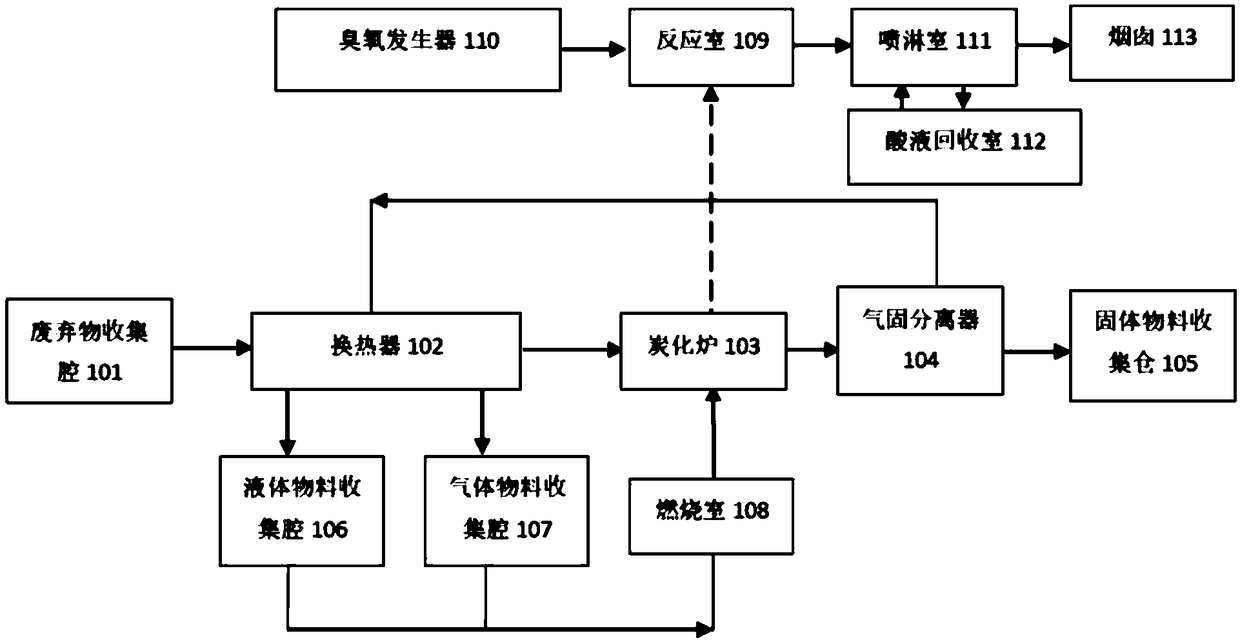

[0017] A solid hazardous waste treatment system such as figure 1 As shown, the solid hazardous waste treatment system at least includes a waste collection chamber 101, a heat exchanger 102, a carbonization furnace 103, a gas-solid separator 104, a liquid material collection chamber 106, a gas material collection chamber 107, a combustion chamber 108, a reaction Chamber 109, ozone generator 110, spray chamber 111, acid recovery chamber 112 and chimney 113.

[0018] Wherein, the waste collection chamber 101 is used to collect solid, liquid and / or gaseous organic waste. The heat exchanger 102 is used for preheating the waste. The carbonization furnace 103 is used to complete the thermal decomposition of organic waste into carbon and other products under air isolation. The gas-solid separator 104 is used to complete the separation of the solid product and the gas product of the carbonized product of the carbonization furnace 103 . The solid material collection bin 105 is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com