Recyclable carbon fiber reinforced epoxy resin composite material, its preparation method and application

A technology for recycling carbon fiber and epoxy resin, which is applied in the field of polymer materials to achieve the effects of simple preparation process, high glass transition temperature and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Another aspect of the embodiments of the present invention provides a method for preparing the aforementioned recyclable carbon fiber reinforced epoxy resin composite material, which includes:

[0041] Pre-cure after uniformly mixing the aldehyde-containing monofunctional epoxy resin, curing agent, curing accelerator, epoxy reactive diluent and solvent to obtain a mixed solution, wherein the aldehyde-containing monofunctional epoxy resin and The curing agent can react to form a Schiff base structure;

[0042] Immersing the carbon fiber in the mixed solution, and then removing the solvent to obtain a carbon fiber prepreg;

[0043] The carbon fiber prepreg is subjected to heat press treatment and post-curing treatment to obtain a recyclable carbon fiber reinforced epoxy resin composite material.

[0044] As one of the preferred embodiments, the mass ratio of the aldehyde-containing monofunctional epoxy resin, curing agent, curing accelerator, epoxy reactive diluent, carb...

Embodiment 1

[0068] (1) Mix 100g of aldehyde-containing monofunctional epoxy resin 1, 80g of ethylenediamine, and 10g of ethanol and pre-cure at 50°C for 50 minutes, soak the carbon fiber unidirectional cloth in the mixed solution for 1min, and then place it in a blast oven The solvent was volatilized at 30°C for 2 hours to obtain a carbon fiber prepreg.

[0069] (2) 10 g of carbon fiber prepreg was hot-pressed at 180° C. under a pressure of 0.5 MPa for 10 minutes, and then post-cured in a vacuum oven at 180° C. for 2 hours to obtain a carbon fiber-reinforced epoxy resin composite material.

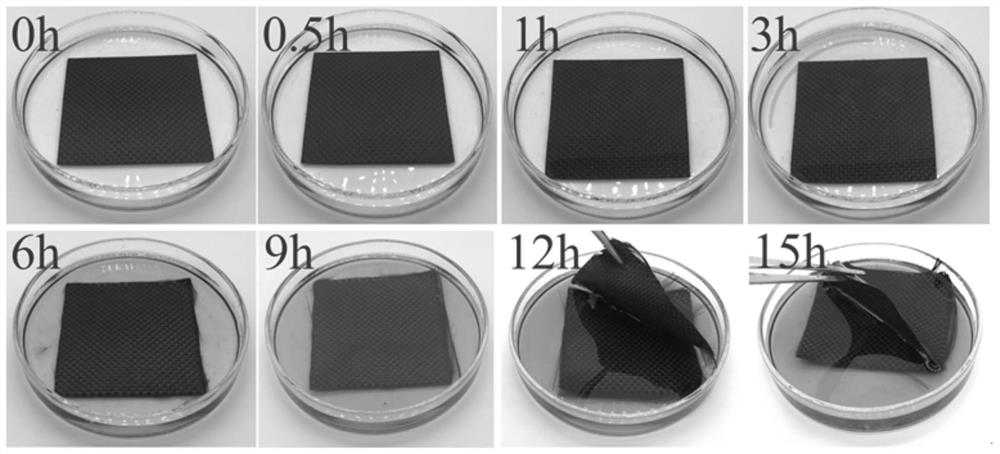

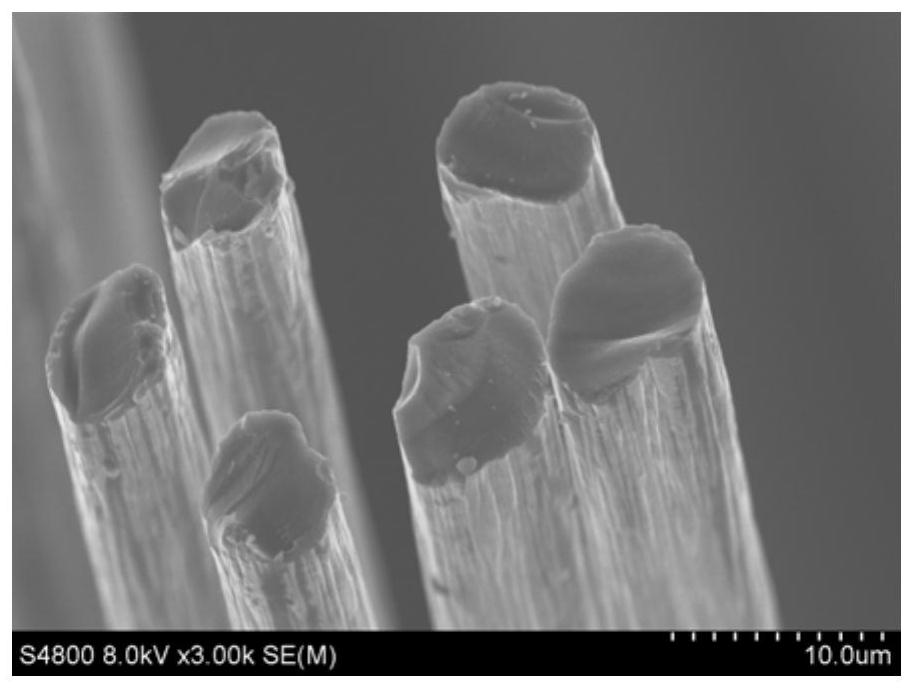

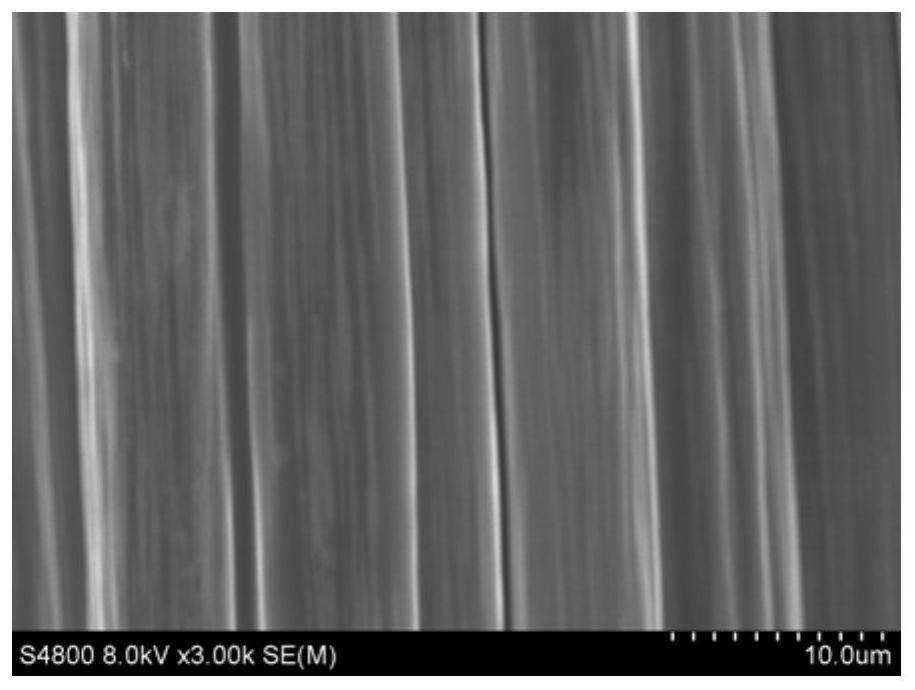

[0070] After testing, the carbon fiber reinforced epoxy resin composite material has a tensile strength of 3600MPa, a tensile modulus of 29GPa, and a glass transition temperature of 180°C, and it can be degraded in a mixed solvent of 0.1M hydrochloric acid and methanol, such as figure 1 shown. The morphology of carbon fibers before and after recycling was characterized by scanning electron microscopy...

Embodiment 2

[0072] Mix 100g of aldehyde-containing monofunctional epoxy resin 1, 90g of butanediamine, 2g of triethylamine, 3g of n-butyl glycidyl ether, and 30g of short fibers, and then cure them at 160°C for 2 hours. After curing for 2 hours, the carbon fiber composite material is obtained.

[0073] After testing, the carbon fiber reinforced epoxy resin composite material has a tensile strength of 800MPa, a tensile modulus of 16GPa, and a glass transition temperature of 140°C, and it can be degraded in a mixed solvent of 0.1M hydrochloric acid and methanol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com