Electrochemical synthesis method of thiazoles compound

An electrochemical and thiazole technology, which is applied in the field of thiazole compound preparation, can solve the problems that the synthesis of thiazole compounds has not been reported in domestic and foreign literature, the post-processing process is complicated, and the environment is seriously polluted. It achieves low cost, low equipment cost, and simple experimental operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

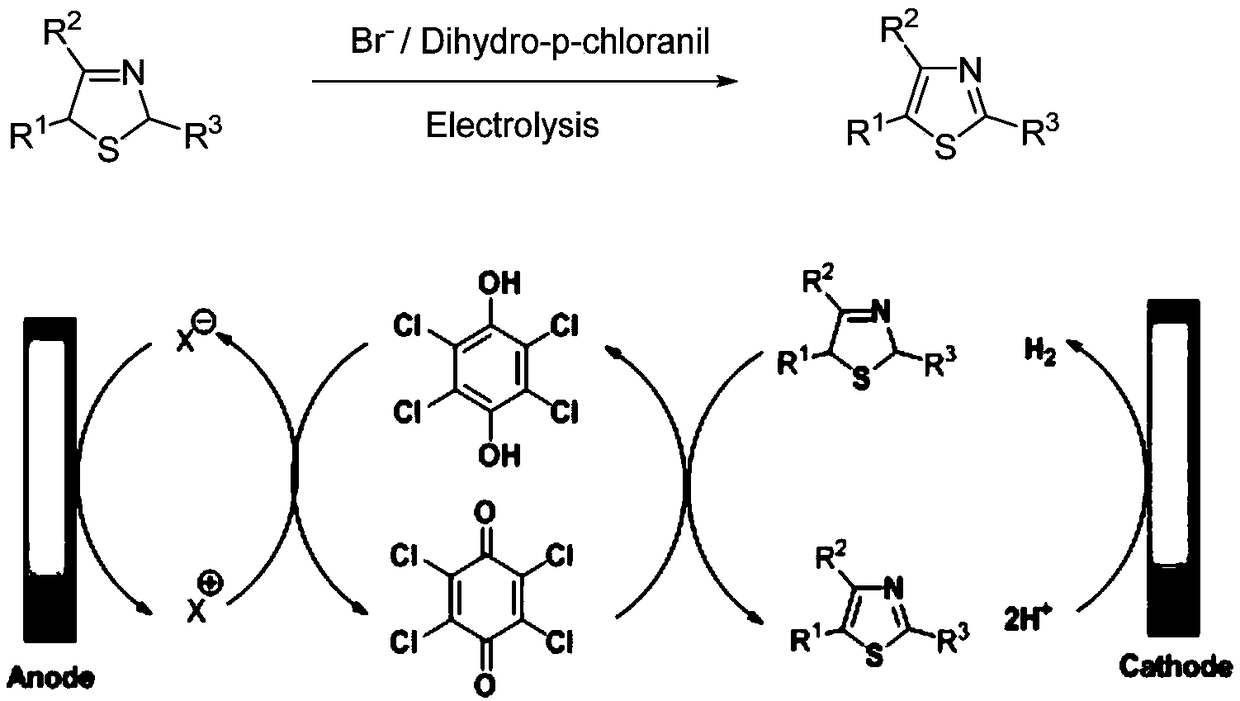

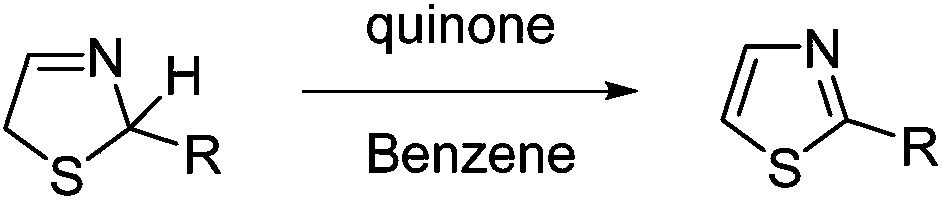

Method used

Image

Examples

Embodiment 1

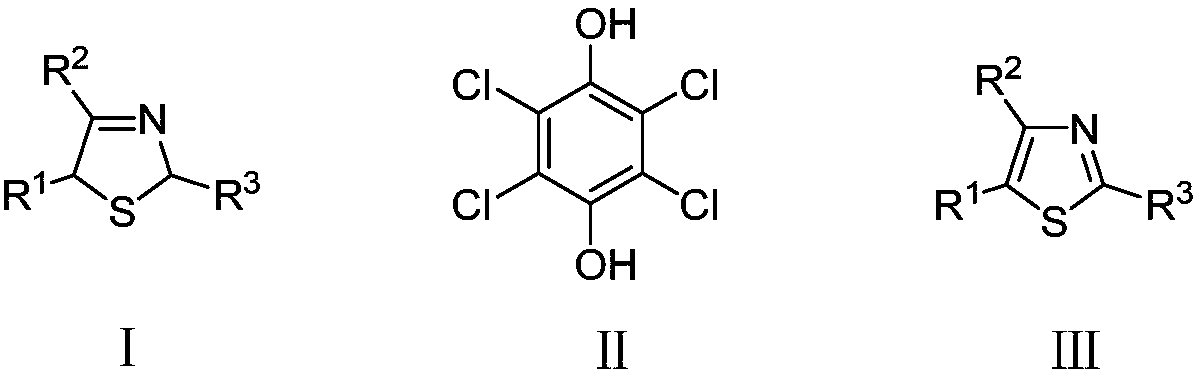

[0040] Embodiment 1: Synthesis of 4,5-dimethyl-2-isobutylthiazole by electrochemical method

[0041] In a 50ml single-chamber electrolytic cell, 4,5-dimethyl-2-isobutylthiazoline (1.0mmol), sodium bromide (1.0mmol), tetrachlorohydroquinone (0.5mmol) were added to 5ml di In the mixed two-phase solvent system of methyl chloride and 5ml water, with the graphite sheet electrode as the anode and the stainless steel mesh as the cathode, at 3mA / cm 2 Electrolyze under constant current, stir at 40°C, stop electrolysis when the current flow reaches 3.0F / mol, cool to room temperature, extract with dichloromethane, wash with sodium hydroxide aqueous solution (0.5M) and water three times, pass through the column Chromatographic separation gives 4,5-dimethyl-2-isobutylthiazole. Yield: 41%.

[0042]

[0043] Yellow liquid; 1 H NMR (400MHz, CDCl 3 )δ0.97(d, J=6.8Hz, 6H), 1.96-2.08(m, 1H), 2.29(s, 3H), 2.30(s, 3H), 2.75(d, J=7.2Hz, 2H); 13 C NMR (100MHz, CDCl 3 )δ11.2, 14.6, 22.3, 29....

Embodiment 2

[0044] Embodiment 2: Synthesis of 4,5-dimethyl-2-isobutylthiazole by electrochemical method

[0045] In a 50ml single-chamber electrolytic cell, 4,5-dimethyl-2-isobutylthiazoline (1.0mmol), sodium bromide (1.0mmol), tetrachlorohydroquinone (0.5mmol) were added to 5ml 1 , In the mixed two-phase solvent system of 2-dichloroethane and 5ml water, with the graphite sheet electrode as the anode and the stainless steel mesh as the cathode, at 3mA / cm 2Electrolyze under constant current, stir at 80°C, stop electrolysis when the current flow reaches 3.0F / mol, cool to room temperature, extract with dichloromethane, wash with sodium hydroxide aqueous solution (0.5M) and water three times, pass through the column Chromatographic separation gives 4,5-dimethyl-2-isobutylthiazole. Yield: 65%.

Embodiment 3

[0046] Example 3: Electrochemical synthesis of 4,5-dimethyl-2-isobutylthiazole

[0047] In a 50ml single-chamber electrolytic cell, 4,5-dimethyl-2-isobutylthiazoline (1.0mmol), sodium bromide (1.0mmol), tetrachlorohydroquinone (0.5mmol) were added to 5ml 1 , In the mixed two-phase solvent system of 2-dichloroethane and 5ml water, with the graphite sheet electrode as the anode and the stainless steel mesh as the cathode, at 3mA / cm 2 Electrolyze under constant current, stir at 60°C, stop electrolysis when the current flow reaches 3.0F / mol, cool to room temperature, extract with dichloromethane, wash with sodium hydroxide aqueous solution (0.5M) and water three times, pass through the column Chromatographic separation gives 4,5-dimethyl-2-isobutylthiazole. Yield: 38%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com