Method for preparing hexafluoropropylene oxide oligomer by using high-activity emulsion layer

A technology of hexafluoropropylene oxide and emulsification layer, which is applied in the preparation of amino compounds, chemical instruments and methods, and the preparation of organic compounds. It can solve problems such as difficult recycling, side reactions, and moisture absorption, and avoid moisture absorption and dissolution. The effect of small size and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A preparation method for a highly active emulsion catalyst, comprising the steps of:

[0032] (1) Add polar aprotic organic solvent, tertiary diamine, triethylamine and acyl fluoride into the reaction kettle at one time in proportion, blow nitrogen gas and stir, and stabilize the temperature in the kettle at 5-40°C with cooling circulating water between;

[0033] Among them, the mass ratio of triethylamine, tertiary diamine and acyl fluoride is 1-10:10-100:50-400; stir for 2-6 hours, then stand for layering, and the beige layer in the middle after layering is the prepared emulsified layer.

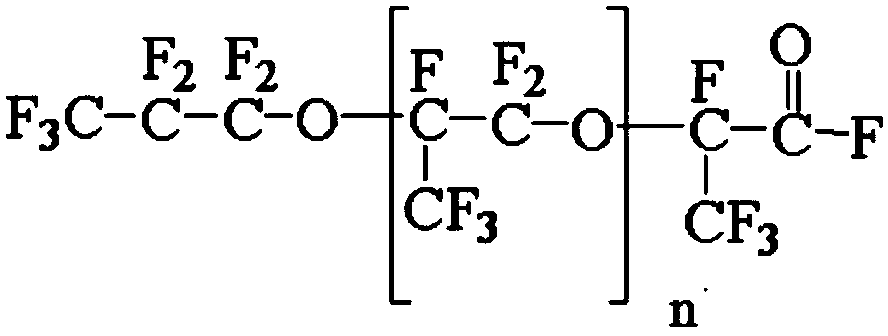

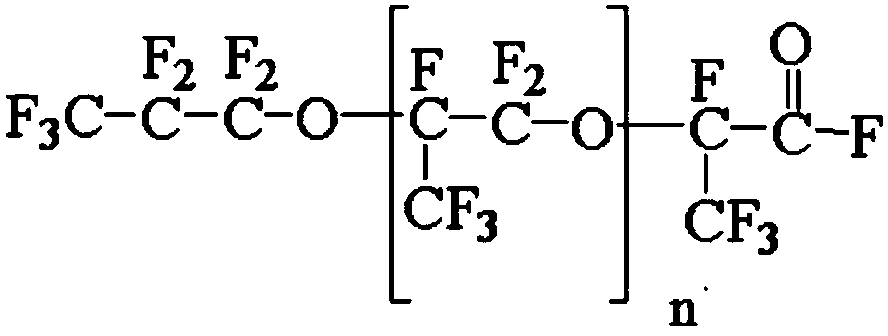

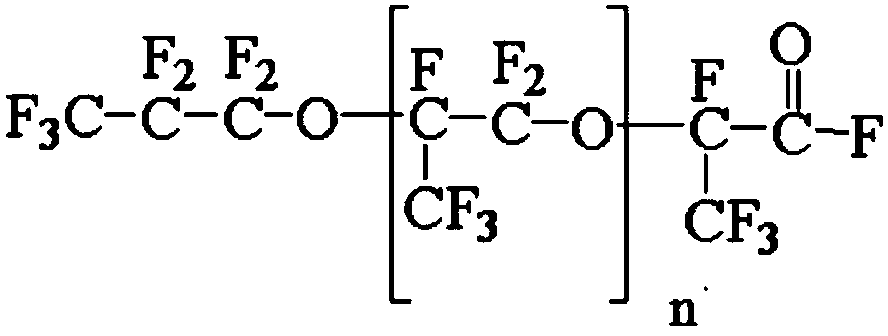

[0034] Wherein, the acyl fluoride includes perfluoropropionyl fluoride or perfluoro-2-methyl-3-oxahexanoyl fluoride. The general formula of the tertiary diamine is R 1 R 2 N-R-NR 3 R 4 , in the general formula, R is a non-branched or branched saturated or unsaturated aliphatic hydrocarbon group with 1 to 12 carbon atoms, R1 and R4 are independent of each other and are aliphati...

preparation example

[0040] Add 150ml of diethylene glycol dimethyl ether, 60g of tetramethylethylenediamine and 1.0g of triethylamine into a stainless steel reaction kettle, continue to add perfluoropropionyl fluoride under the protection of nitrogen atmosphere and keep stirring, and use cooling circulating water to The temperature in the kettle during the reaction was maintained at about 25°C. After adding 200g of perfluoropropionyl fluoride, the reaction stops, continue to stir for 1-2 hours, let it stand for 0.5 hours, discharge the material from the bottom of the reaction kettle, and put it in the separating funnel to separate layers, and the beige emulsion in the lower layer is the desired product. Prepared emulsion layer.

[0041] The preparation method of the fluoropropylene oxide oligomer is prepared by the highly active emulsification layer catalyst prepared by the above method, comprising the steps:

[0042] a. Take a certain amount of high-activity emulsification layer in a solvent in...

Embodiment 1

[0056] Add 150ml of diethylene glycol dimethyl ether and 50.0g of the emulsified layer into a dry stainless steel reaction kettle quickly, and pass high-purity nitrogen to drive away the air in the kettle and the white smoke generated by the emulsified layer. And stir about 1h under the protection of nitrogen atmosphere, release the nitrogen in the kettle so that the initial pressure in the reactor is 0, HFPO is passed into the reactor at a rate of 200 sccm for reaction, and the temperature in the reactor during the reaction is maintained at Around 25°C. After feeding 250g of HFPO, stop feeding HFPO, the reaction stops, continue to stir for 1h, let it stand for 0.5h, discharge from the bottom of the reaction kettle, put it in the separatory funnel and put it into layers, the upper layer is the solvent, and the middle layer is emulsified layer, the lower layer is a transparent liquid which is hexafluoropropylene oxide oligomer, and 249.7 g of the crude product is obtained with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com