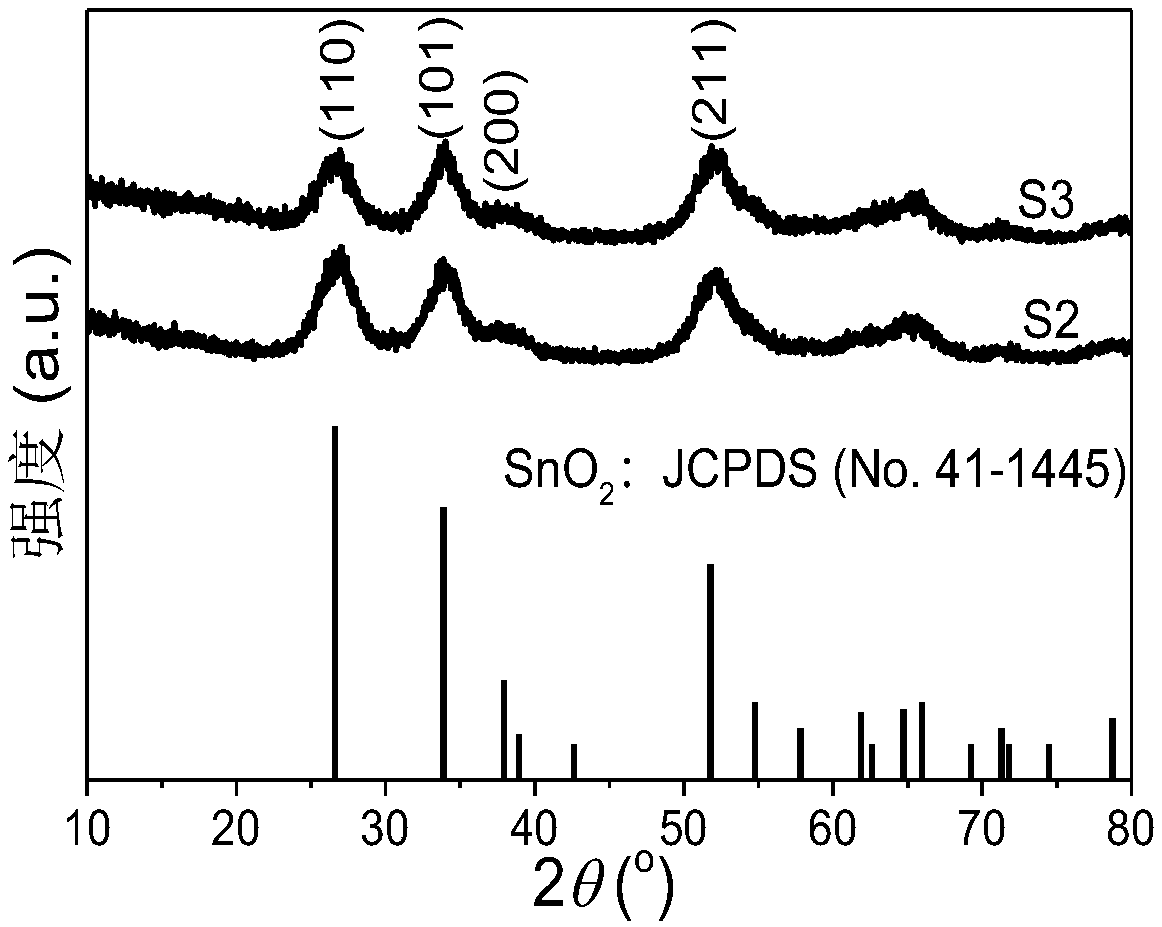

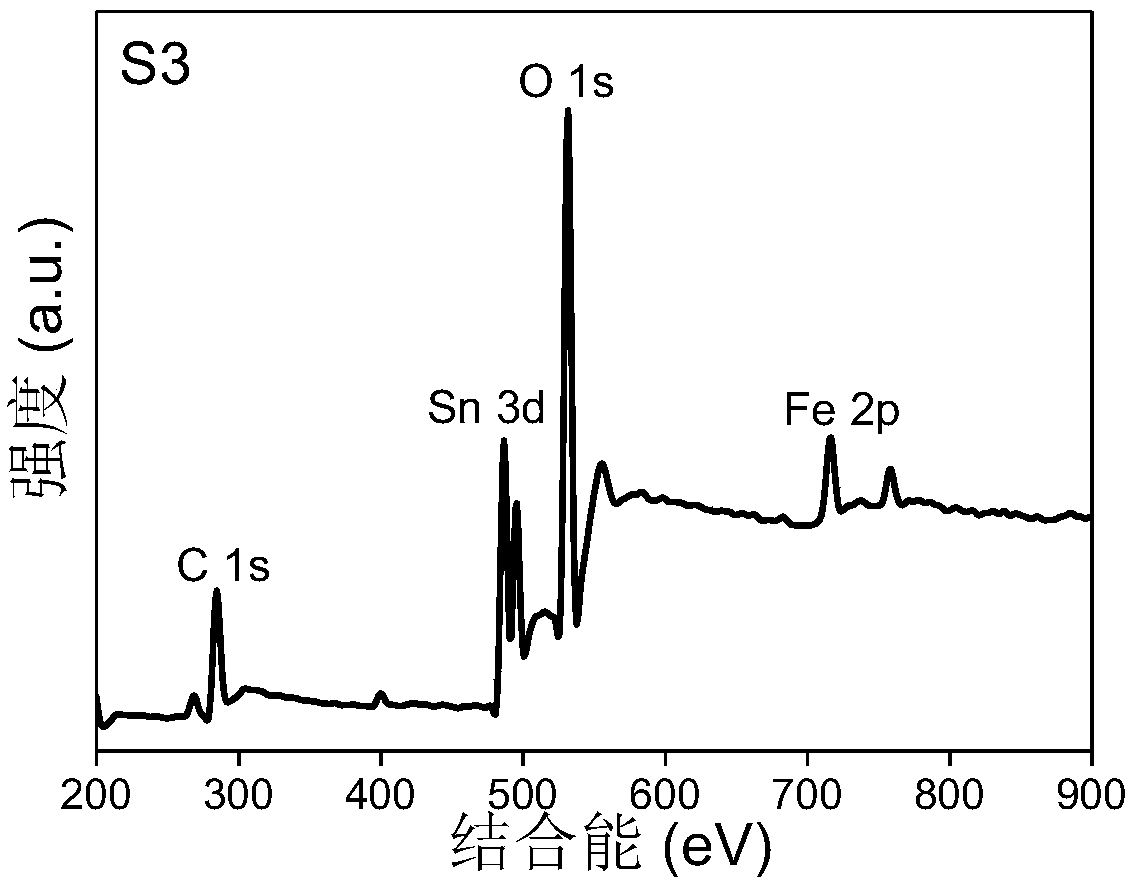

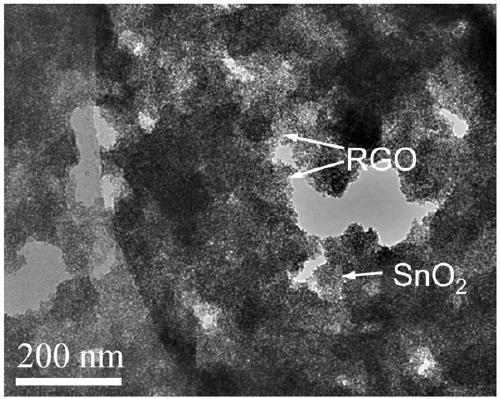

Preparation method of Fe-doped stannic oxide/reduced graphene oxide nanometer composite wave absorption material

A nano-composite material and tin dioxide technology, which is applied in the field of electromagnetic composite materials, can solve the problems of high density and narrow absorption frequency band, and achieve the effects of enhancing absorption capacity, easy operation and good wave absorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Take a 100mL beaker, add 30mL deionized water, add 20mg graphite oxide while stirring, sonicate for 30min, stir vigorously for 2h, and prepare a graphene oxide (GO) aqueous dispersion with a concentration of 0.67mg / mL;

[0032] 2. Add 1.550g tin tetrachloride pentahydrate (SnCl 4 ·5H 2 0), vigorously stirred for 30min to make it dissolve completely;

[0033] 3. Add ammonia water drop by drop to adjust the pH of the mixed dispersion to 10, then stir vigorously for 15 minutes;

[0034] 4. Transfer the mixed dispersion to a reaction kettle with a volume of 50mL, and conduct a hydrothermal reaction at 160°C for 18h;

[0035] 5. After the reaction, cool to room temperature, repeat centrifugation, and wash with deionized water several times to make the pH of the product reach neutral;

[0036] 6. Transfer the product to a vacuum drying oven, dry at 55°C for 24 hours, and grind to obtain the final product, which is designated as S1.

[0037] The powder product and paraf...

Embodiment 2

[0039] 1. Take a 100mL beaker, add 30mL deionized water, add 20mg graphite oxide while stirring, sonicate for 30min, stir vigorously for 2h, and prepare a graphene oxide (GO) aqueous dispersion with a concentration of 0.67mg / mL;

[0040] 2. Add 1.550g tin tetrachloride pentahydrate (SnCl 4 ·5H 2 O), after stirring evenly, add 0.095g ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) Stir vigorously for 30 min to dissolve completely. Among them, iron ions (Fe 3+ ) accounted for Fe 3+ and tin ions (Sn 4 + ) mole percent 5mol.%;

[0041] 3. Add ammonia water drop by drop to adjust the pH of the mixed dispersion to 10, then stir vigorously for 15 minutes;

[0042] 4. Transfer the mixed dispersion to a reaction kettle with a volume of 50mL, and conduct a hydrothermal reaction at 160°C for 18h;

[0043] 5. After the reaction, cool to room temperature, repeat centrifugation, and wash with deionized water several times to make the pH of the product reach neutral;

[0044]6. Tr...

Embodiment 3

[0047] 1. Take a 100mL beaker, add 30mL deionized water, add 20mg graphite oxide while stirring, sonicate for 30min, stir vigorously for 2h, and prepare a graphene oxide (GO) aqueous dispersion with a concentration of 0.67mg / mL;

[0048] 2. Add 1.550g tin tetrachloride pentahydrate (SnCl 4 ·5H 2 O), after stirring evenly, add 0.190g ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) Stir vigorously for 30 min to dissolve completely. Among them, iron ions (Fe 3+ ) accounted for Fe 3+ and tin ions (Sn 4 + ) mole percent 10mol.%;

[0049] 3. Add ammonia water drop by drop to adjust the pH of the mixed dispersion to 10, then stir vigorously for 15 minutes;

[0050] 4. Transfer the mixed dispersion to a reaction kettle with a volume of 50mL, and conduct a hydrothermal reaction at 160°C for 18h;

[0051] 5. After the reaction, cool to room temperature, repeat centrifugation, and wash with deionized water several times to make the pH of the product reach neutral;

[0052] 6. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com