Method for treating wastewater with high sulfate and high COD

A high sulfate and treatment method technology, applied in water/sewage treatment, water treatment parameter control, water/sewage multi-stage treatment, etc., can solve the troublesome maintenance and cleaning of anaerobic reactors, high safety requirements, and difficult to filter sediments and other problems, to achieve the effect of facilitating anaerobic oxidation treatment, simple treatment process operation, and convenient reaction and regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment relates to the treatment of high sulfate and high COD wastewater.

Embodiment 11

[0028] For SO from the neomycin sulfate production process 4 2- The high sulfate and high COD wastewater with a concentration of 9560mg / L and a COD concentration of 30500mg / L shall be treated as follows:

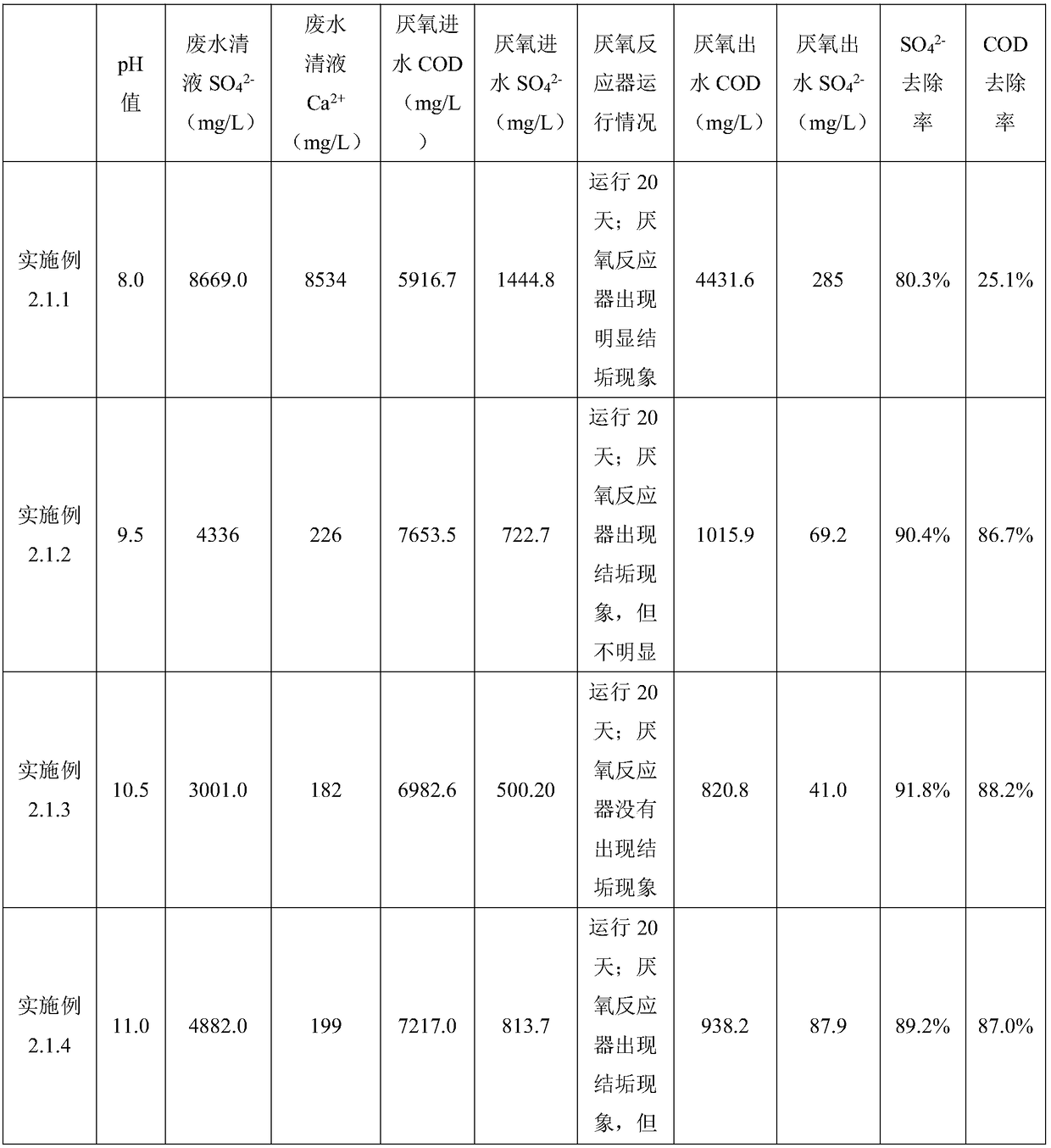

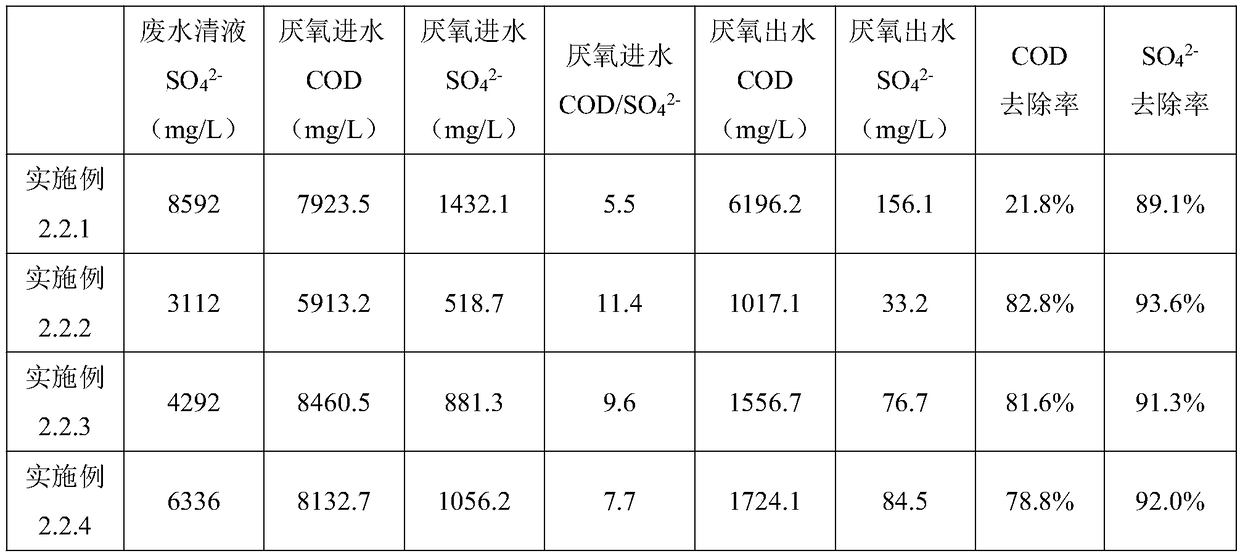

[0029] a. Precipitation: The high sulfate and high COD wastewater to be treated is transported to the reaction tank, and the alumina aqueous solution dissolved to a concentration of 4000mg / L is first added to the high sulfate and high COD wastewater in the pipeline through the pipeline mixer. Then add Ca to the wastewater in the reaction tank 2+Calcium oxide solution with a concentration of 40000mg / L, adjust the pH of the wastewater to 10.5, fully stir the reaction to form ettringite precipitation, and add the amount of alumina and calcium oxide that is about 4 2- 1.2 times the number of moles, SO in wastewater 4 2- When the concentration drops to about 3000mg / L, the wastewater is transported to the sedimentation tank for sedimentation treatment, and the wastewater clea...

Embodiment 12

[0033] For SO from streptomycin sulfate production process 4 2- The high sulfate and high COD wastewater with a concentration of 11200mg / L and a COD concentration of 35000mg / L shall be treated as follows:

[0034] a. Precipitation: The high sulfate and high COD wastewater to be treated is transported to the reaction tank, and the polymerized AlCl with a solid content of 11000mg / L 3 The solution is added to the high sulfate and high COD wastewater in the delivery pipeline through a pipeline mixer, and then Ca is added to the wastewater in the reaction tank. 2+ Calcium chloride solution with a concentration of 27000mg / L, adjust the pH of the wastewater to 10.0, stir the reaction fully to form ettringite precipitation, add polymerized AlCl 3 The amount of calcium chloride and calcium chloride is about 4 2- 1.2 times the number of moles, SO in wastewater 4 2- When the concentration drops to about 4000mg / L, the wastewater is transported to the sedimentation tank for sedimenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com