Method for preparing lignin hydrogel

A technology of lignin and hydrogel, applied in the field of preparation of lignin hydrogel, can solve the problems of poor mechanical properties, poor dye adsorption performance, etc., achieve high compressive tensile strength, biocompatibility, environmental friendliness, and preparation short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Using the frequency of 25kHz, under the power of 800W, the lignin aqueous solution was subjected to ultrasonic treatment for 60 minutes by an ultrasonic probe (JY98-3D, Ningbo Xinzhi Biotechnology Co., Ltd.), to prepare a lignin nanoparticle suspension; 1.7g Acrylamide monomer and 0.01g N,N'-methylenebisacrylamide were mixed with 3mL lignin nanoparticle suspension, and after stirring the mixture for 15 minutes, 100μL ascorbic acid (AA, 6wt%) and 100μL Hydrogen peroxide (H 2 o 2 , 30wt%) aqueous solution as the initiator. The reaction was stirred for an additional 30 minutes in order to thoroughly mix the components. Finally, the uniformly mixed reaction solution was placed in a water bath environment at 70°C for free radical polymerization. After 9 hours of reaction, the prepared hydrogel was soaked in deionized water for 48 hours to remove unreacted monomers and other Impurities.

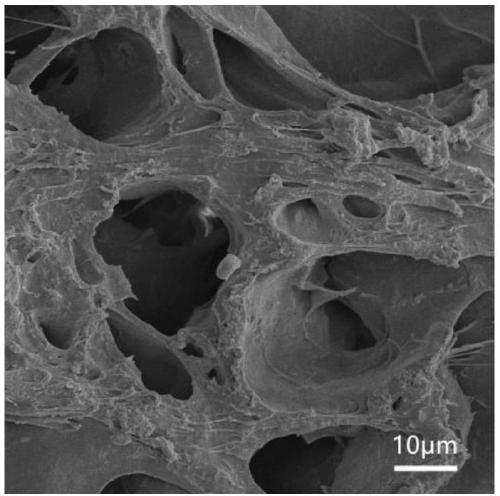

[0029] Scanning electron microscope analysis was performed on the lignin hydrogel ob...

Embodiment 2

[0032] Using a frequency of 25kHz and a power of 800W, an ultrasonic probe (JY98-3D, Ningbo Xinzhi Biotechnology Co., Ltd.) was used to ultrasonicate the lignin aqueous solution for 60 minutes to prepare multiple groups of lignin nanoparticle suspensions with different contents. liquid; mix 1.7g of acrylamide monomer and 0.01g of N,N'-methylenebisacrylamide with 3mL of lignin nanoparticle (4.5wt%) suspension, stir the mixture for 15 minutes, then add 100 μL of an aqueous solution of ammonium persulfate (6wt%) was used as an initiator; in order to fully mix the components, the reaction solution was stirred for another 30 minutes, and finally, the uniformly mixed reaction solution was placed in a water bath environment at 70°C for free radical polymerization , after reacting for 9 hours, the prepared hydrogel was soaked in deionized water for 48 hours to remove unreacted monomers and other impurities.

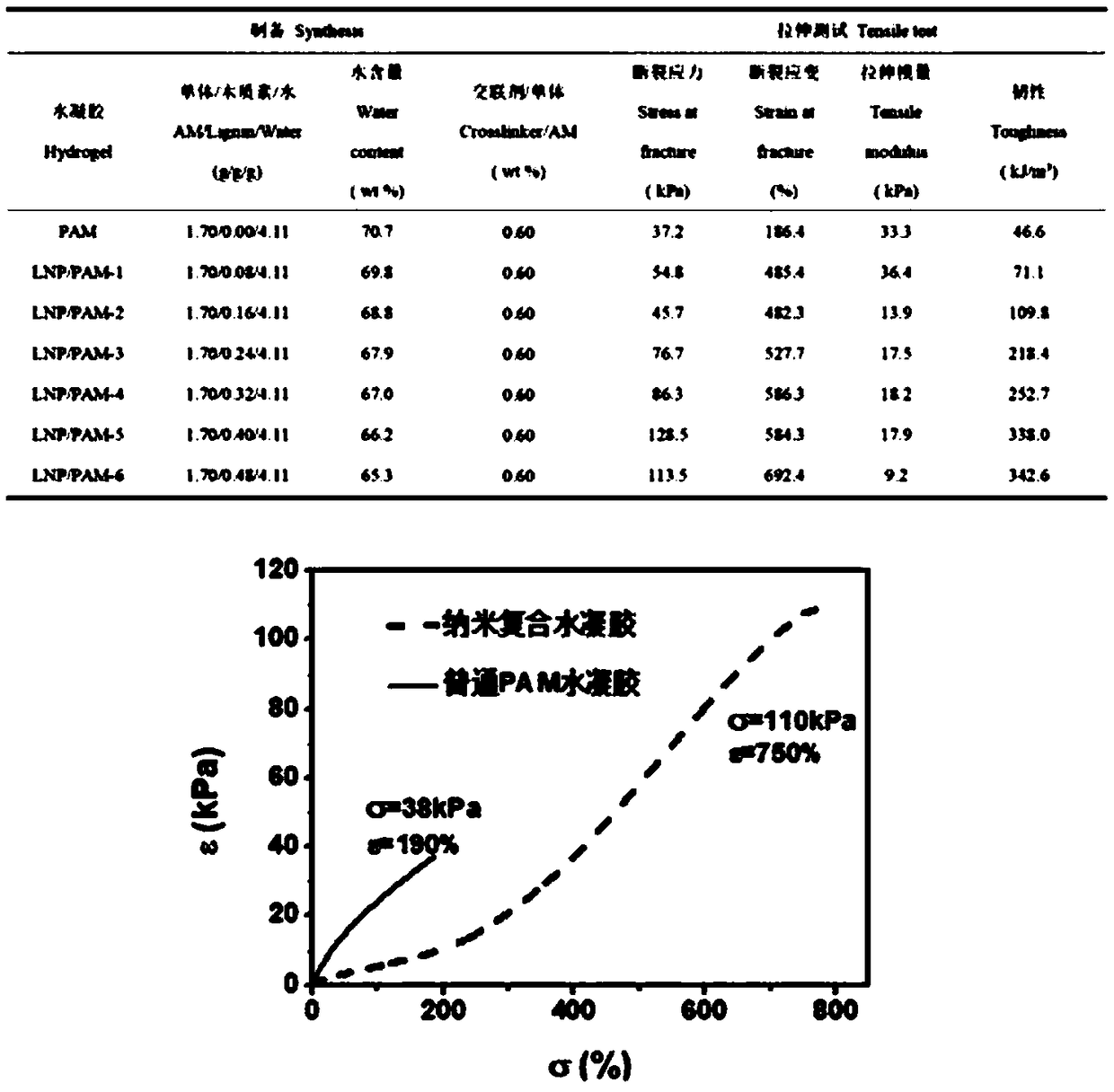

[0033] Replace the lignin nanoparticle suspensions with solid contents of 8....

Embodiment 3

[0037] Using the frequency of 25kHz, under the power of 800W, the lignin aqueous solution was subjected to ultrasonic treatment for 60 minutes by an ultrasonic probe (JY98-3D, Ningbo Xinzhi Biotechnology Co., Ltd.), to prepare a lignin nanoparticle suspension; 1.7g Acrylamide monomer and 0.01 g of N,N'-methylenebisacrylamide were mixed with 3 mL of lignin nanoparticle suspension, and after stirring the mixture for 15 minutes, 100 μL of potassium persulfate solution was added to the mixture as an initiator. The reaction was stirred for an additional 30 minutes in order to thoroughly mix the components. Finally, the uniformly mixed reaction solution was placed in a water bath environment at 70°C for free radical polymerization. After 9 hours of reaction, the prepared hydrogel was soaked in deionized water for 48 hours to remove unreacted monomers and other Impurities.

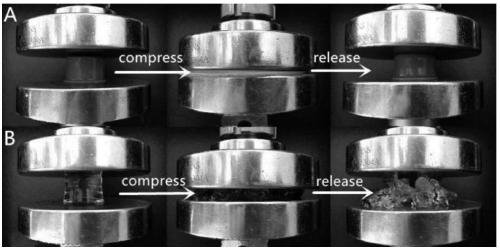

[0038]Compression performance tests were carried out on the lignin hydrogel prepared in this example and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com