Method and application of preparing total triterpenes with hypoglycemic effect from Cyclocarya paliurus leaves

A technology for total triterpenes and hypoglycemia, which is applied in the field of medicine and food, and can solve problems such as no research or report on the preparation process of total triterpenes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

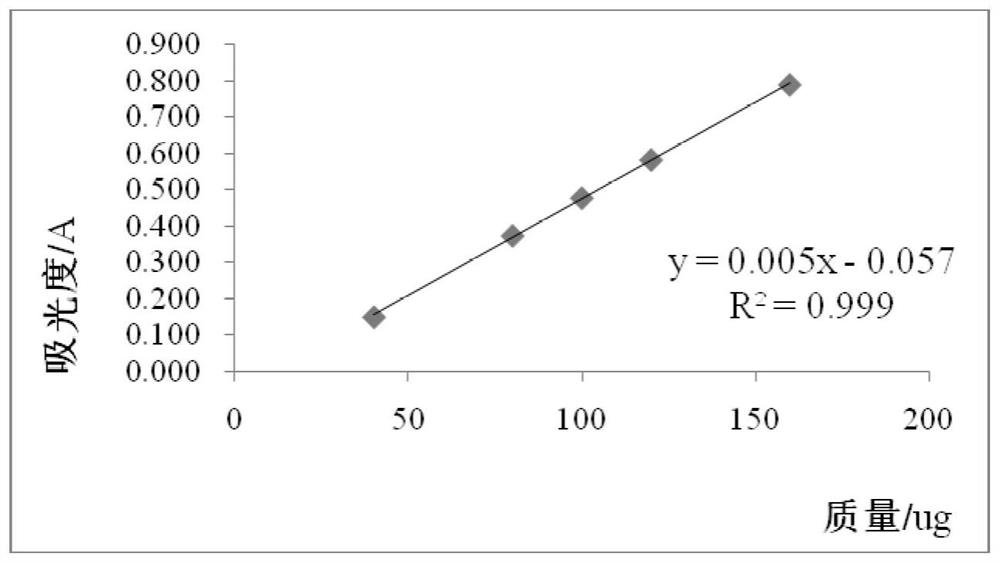

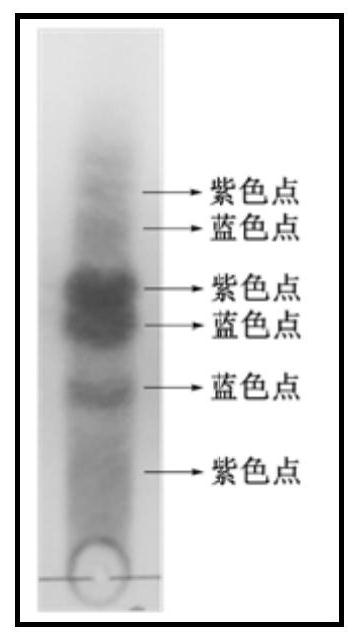

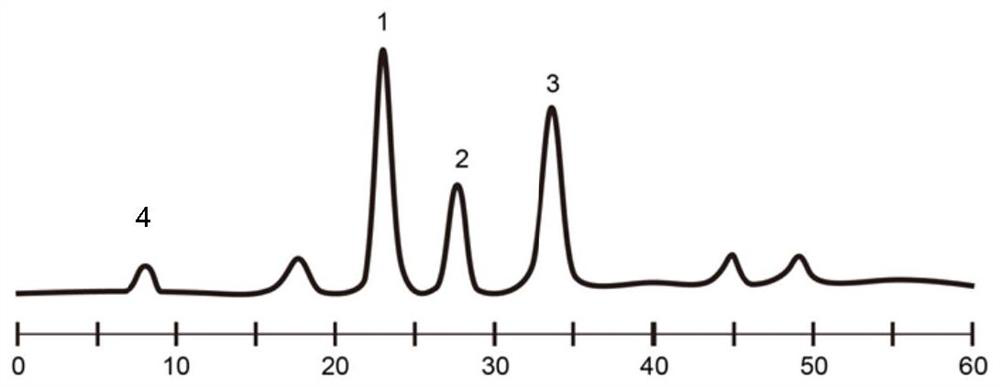

[0020] Dry 5 kg of Cyclocarya paliurus leaves, grind into powder, and extract twice at room temperature with 50 L of 80% ethanol solution, each time for 5 days. The combined extracts were concentrated under reduced pressure to dryness to obtain a total extract of 750 g. The total extract was dispersed with 1 L of water, and extracted with petroleum ether and chloroform in equal volumes respectively to obtain 280 g of the chloroform extract. The chloroform extraction part was eluted by a 60-80 mesh polyamide chromatographic column (dichloromethane: methanol = 15:1), and the eluted part was collected to obtain an extract. Then dissolve the extract with water, adsorb on the AB-8 macroporous resin column, first wash away impurities with 30% ethanol, and then elute with 60% ethanol. The 60% ethanol eluate was collected and concentrated to dryness under reduced pressure to obtain 105 g of dry powder of total triterpenes, with a total extraction rate of 2.1%. The total triterpene c...

Embodiment 2

[0022] 10 kg of dried Cyclocarya paliurus leaves were powdered and refluxed with 80 L of 70% ethanol solution twice for 2 hours each time. The combined extracts were concentrated under reduced pressure to dryness to obtain 1600 g of the total extract. The total extract was dispersed with 2L of water, extracted successively with equal volumes of petroleum ether and ethyl acetate to obtain 560 g of ethyl acetate extract. The ethyl acetate extraction part was eluted by a 100-200 mesh polyamide column (petroleum ether: acetone = 1:1), and the eluted part was collected to obtain an extract. Then dissolve the extract with water, adsorb on D101 macroporous resin column, first wash away impurities with 40% ethanol, and then elute with 70% ethanol. The 70% ethanol eluate was collected and concentrated to dryness under reduced pressure to obtain 280 g of dry powder of total triterpenes, with a total extraction rate of 2.8%. The measured triterpene content was 85.4%.

Embodiment 3

[0024] Dry 1 kg of Cyclocarya paliurus leaves, powder them, and extract twice with 10 L of 90% ethanol under reflux, each time for 100 min. The combined extracts were concentrated under reduced pressure to dryness to obtain a total extract of 182 g. The total extract was dispersed with 500 mL of water, extracted successively with equal volumes of petroleum ether and ethyl acetate: n-butanol (10:1), to obtain 65 g of ethyl acetate-n-butanol extract. The extracted part was eluted by a 100-200 mesh polyamide column (dichloromethane: ethyl acetate = 2:1), and the eluted part was collected to obtain the total triterpene extract. Then dissolve the extract with water, adsorb on the DM130 macroporous resin column, first wash away impurities with 50% ethanol, and then elute with 90% ethanol. The 90% ethanol eluate was collected and concentrated to dryness under reduced pressure to obtain 25 g of dry powder of total triterpenes with a total extraction rate of 2.5%. The measured triter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com