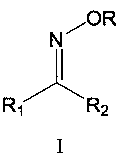

Oxime ether synthesis method

A technology for oxime ether and ketoxime, which is applied in the field of synthesizing oxime ether, can solve the problems of high production cost, high loss, high unit price, etc., and achieves the effects of avoiding corrosion, avoiding discharge, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

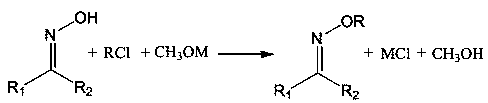

Method used

Image

Examples

Embodiment 1

[0023] In a 1000ml autoclave, add 87g (1mol) methyl ethyl ketone oxime (purity: 98%), 54g (1mol) sodium methoxide, 300ml anhydrous DMF, pass into 60g (1.2mol) methylene chloride, Sealed reaction at 30°C for 6h. Cool to room temperature after the reaction, filter the reaction liquid, wash the filter residue with DMF, combine the filtrate and washing liquid, carry out precipitation and rectification, collect the fraction at 80-83°C, and obtain the pure product butanone-O-methyloxime Ether, the yield is 80%, and the purity is 99%.

Embodiment 2

[0025] Replace 87g (1mol) of methyl ethyl ketone oxime (99% in purity) with 73g (1mol) of acetone oxime (99% in purity), and collect fractions at 75-78°C during rectification. Other conditions and operating procedures are the same as in the examples 1. Obtain the pure product acetone-O-methyl oxime ether with a yield of 83% and a purity of 99%.

Embodiment 3

[0027] Replace 87g (1mol) methyl ethyl ketoxime (99% purity) with 101g (1mol) methyl propyl ketone oxime (purity 99%), collect fractions at 127~130°C during rectification, other conditions and operations The process was the same as in Example 1, and the pure product methyl propyl ketone-O-methyl oxime ether was obtained, with a yield of 75% and a purity of 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com