Low-aldehyde high-temperature-resistant polyurethane material and preparation method thereof

A technology of polyurethane material and high temperature resistance, which is applied in the field of polyurethane materials, can solve the problems of high temperature resistance and poor flame retardancy, and achieve the effects of increased rigidity, improved environmental protection performance, and increased content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

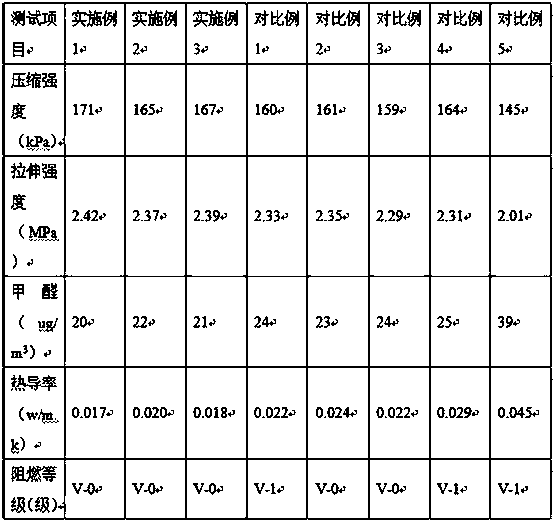

Examples

preparation example Construction

[0026] The preparation method of polyurethane base thing is:

[0027] Take formaldehyde and add deionized water according to the mass ratio of 1~3:3~5 to obtain a mixed solution, add diethanolamine to the mixed solution according to the mass ratio of 4~9:3~7, stir and mix at 25~30°C for 30~40min to obtain a mixed solution Mixture, take the stirred mixture and add it dropwise to lignin according to the mass ratio of 3~7:10~15, control the dropping time for 30~50min, heat up to 30~40°C, stir and mix for 2~4h, and distill under reduced pressure to obtain Take the vacuum distillate and add phthalic anhydride polyester polyol PS-400A and polymer polyol TPOP36 / 28 in a mass ratio of 10~20:3~7:2~5 and mix to obtain a polyurethane matrix.

[0028] The preparation method of polyurethane modified active agent is:

[0029] Take 4(4-hydroxy-phenyl)-2,3-diazepinone, add sodium hydroxide and deionized water in a mass ratio of 2~5:1~3:8~10, heat up to 55~60°C and stir Mix for 30-50 minutes,...

Embodiment 1

[0040] Brucite powder: 2500 mesh.

[0041] The preparation method of polyurethane base thing is:

[0042] Take formaldehyde and add deionized water at a mass ratio of 1:3 to obtain a mixed solution, add diethanolamine to the mixed solution at a mass ratio of 4:3, stir and mix at 25°C for 30 minutes to obtain a stirred mixture, take the stirred mixture at a mass ratio of 3:10 drops Add it to lignin, control the dropping time for 30 minutes, heat up to 30°C, stir and mix for 2 hours, distill under reduced pressure to obtain a reduced-pressure distillate, take the reduced-pressure distillate and add phthalic anhydride polyester polyol PS at a mass ratio of 10:3:2 Mix -400A and polymer polyol TPOP36 / 28 to obtain polyurethane matrix.

[0043] The preparation method of polyurethane modified active agent is:

[0044] Take 4(4-hydroxy-phenyl)-2,3-diazepinone, add sodium hydroxide and deionized water at a mass ratio of 2:1:8, heat up to 55°C and stir for 30 minutes, then add sodium h...

Embodiment 2

[0055] Brucite powder: 2500 mesh.

[0056] The preparation method of polyurethane base thing is:

[0057] Take formaldehyde and add deionized water at a mass ratio of 2:4 to obtain a mixed solution, add diethanolamine to the mixed solution at a mass ratio of 6:5, stir and mix at 28°C for 35 minutes to obtain a stirred mixture, take the stirred mixture at a mass ratio of 5:13 drops Add it to lignin, control the dropping time for 40 minutes, raise the temperature to 35°C, stir and mix for 3 hours, distill under reduced pressure to obtain a reduced-pressure distillate, take the reduced-pressure distillate and add phthalic anhydride polyester polyol PS at a mass ratio of 15:5:4 Mix -400A and polymer polyol TPOP36 / 28 to obtain polyurethane matrix.

[0058] The preparation method of polyurethane modified active agent is:

[0059] Take 4(4-hydroxy-phenyl)-2,3-diazepinone, add sodium hydroxide and deionized water in a mass ratio of 4:2:9, heat up to 58°C and stir for 40 minutes, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com