High anti-corrosion alloy panel for industrial heat dissipator and preparation process thereof

An anti-corrosion alloy and heat sink technology, which is applied in the field of alloy casting, can solve the problems of comprehensive mechanical properties, processing properties and protection performance constraints, affecting the effective service life of radiator products, poor controllability of interlayer bonding force, etc., to achieve mechanical properties Improvement, stability, and anti-corrosion and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

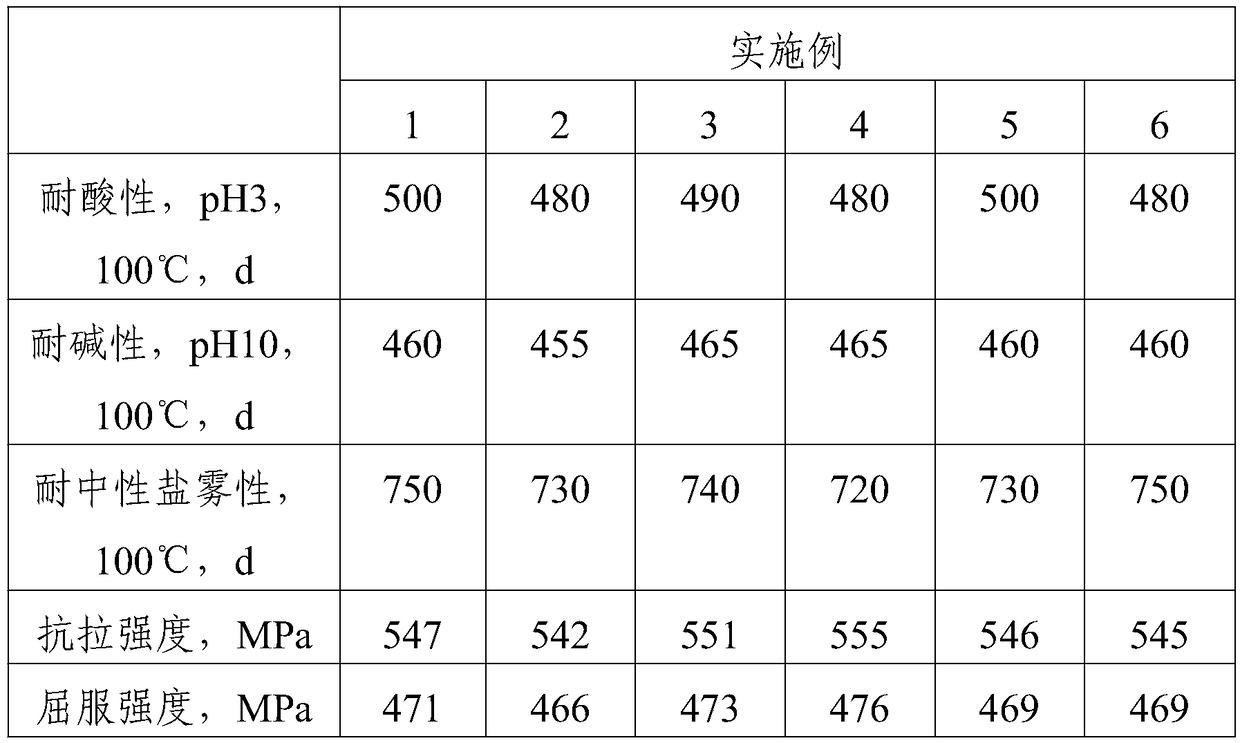

Examples

Embodiment 1

[0028] A high anti-corrosion alloy plate for industrial radiators, comprising a strengthening alloy and an outer cladding layer coated on the outside of the strengthening alloy, the strengthening alloy includes an alloy body and an anti-corrosion layer a and an anti-corrosion layer b sprayed on the outside of the alloy body, the The alloy body adopts B-Ti-Te-Co-Al alloy system, and the anti-corrosion layer a includes the following components: tantalum nitride powder, titanium nitride powder, tin bronze powder, fluorophlogopite powder, aluminum powder; The anticorrosion layer b includes the following components: titanium nitride powder, magnesium nitride powder, and zinc oxide powder; the outer coating layer is a composite coating of organic silicon-alkyd resin-S-148 aromatic alcohol unsaturated polyester resin.

[0029] in:

[0030]The thicknesses of the anti-corrosion layer a, anti-corrosion layer b and outer coating layer are respectively 0.4%, 0.5% and 0.5-1.5% of the thick...

Embodiment 2

[0039] A high anti-corrosion alloy plate for industrial radiators, comprising a strengthening alloy and an outer cladding layer coated on the outside of the strengthening alloy, the strengthening alloy includes an alloy body and an anti-corrosion layer a and an anti-corrosion layer b sprayed on the outside of the alloy body, the The alloy body adopts B-Ti-Te-Co-Al alloy system, and the anti-corrosion layer a includes the following components: tantalum nitride powder, titanium nitride powder, tin bronze powder, fluorophlogopite powder, aluminum powder; The anticorrosion layer b includes the following components: titanium nitride powder, magnesium nitride powder, and zinc oxide powder; the outer coating layer is a composite coating of organic silicon-alkyd resin-S-148 aromatic alcohol unsaturated polyester resin.

[0040] in:

[0041] The thickness of the anti-corrosion layer a, anti-corrosion layer b and outer coating layer are respectively 0.6%, 0.8% and 1.0% of the thickness ...

Embodiment 3

[0050] A high anti-corrosion alloy plate for industrial radiators, comprising a strengthening alloy and an outer cladding layer coated on the outside of the strengthening alloy, the strengthening alloy includes an alloy body and an anti-corrosion layer a and an anti-corrosion layer b sprayed on the outside of the alloy body, the The alloy body adopts B-Ti-Te-Co-Al alloy system, and the anti-corrosion layer a includes the following components: tantalum nitride powder, titanium nitride powder, tin bronze powder, fluorophlogopite powder, aluminum powder; The anticorrosion layer b includes the following components: titanium nitride powder, magnesium nitride powder, and zinc oxide powder; the outer coating layer is a composite coating of organic silicon-alkyd resin-S-148 aromatic alcohol unsaturated polyester resin.

[0051] in:

[0052] The thickness of the anti-corrosion layer a, anti-corrosion layer b and outer coating layer are respectively 0.6%, 0.8% and 1.5% of the thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com