A method of hydrogenated silicone oil modified nano silicon dioxide

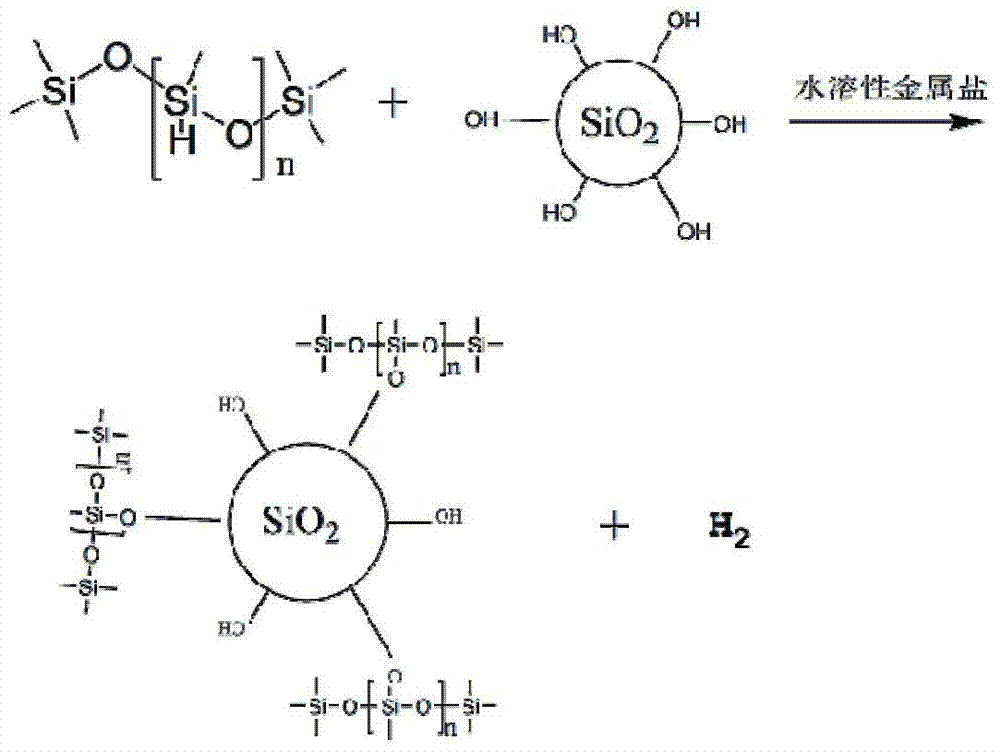

A technology of nano-silica and hydrogenated silicone oil, which is applied in the treatment of dyed organic silicon compounds, fibrous fillers, coatings, etc., to achieve the effects of inhibiting agglomeration, improving stability, and low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

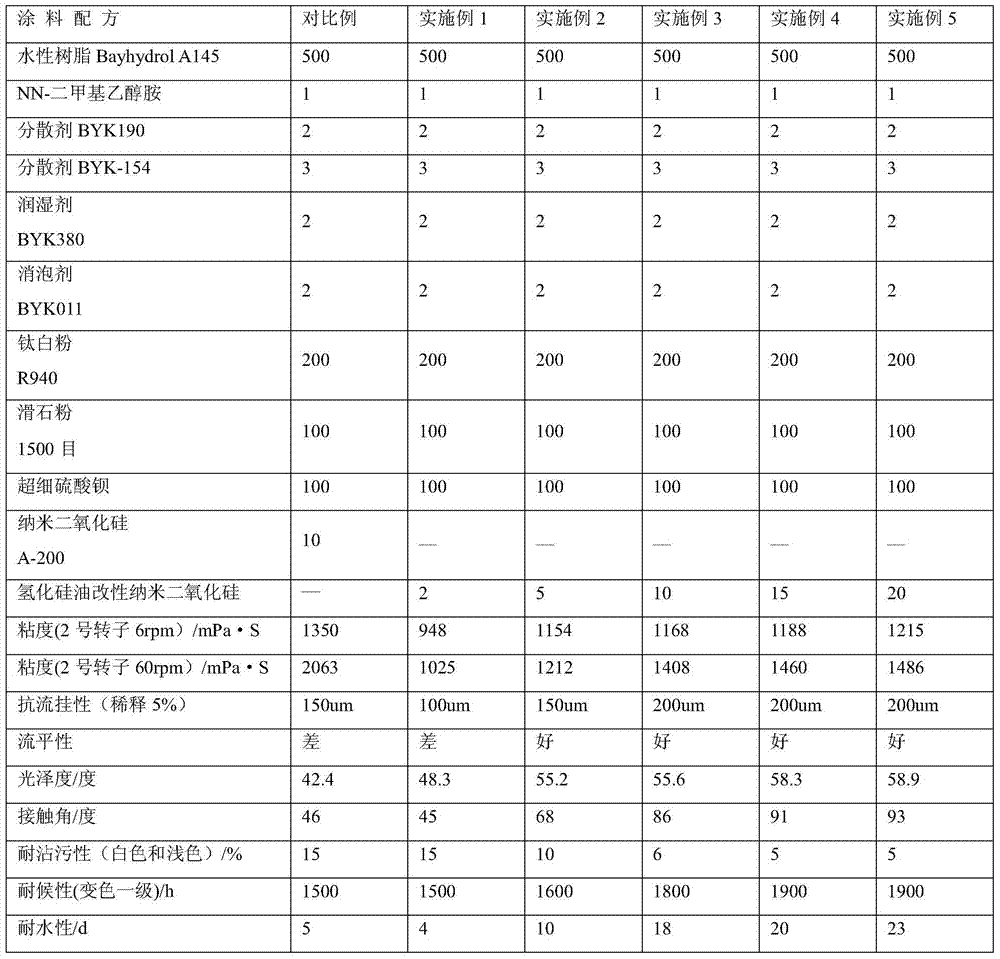

Examples

Embodiment 1

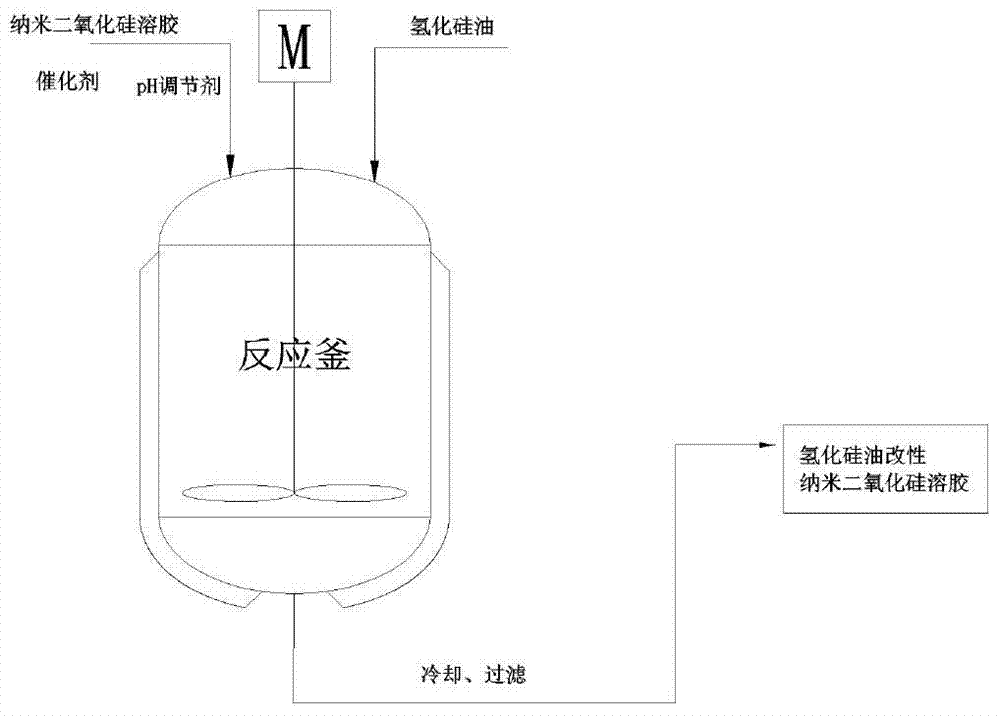

[0015] The formula and processing technology are as follows:

[0016] Add 90Kg of nano-silica sol to be treated and 0.05Kg of water-soluble metal salt stannous sulfate into a sealed kettle with a stirring and heating device, start stirring, add 0.05Kg of triethanolamine pH regulator to adjust pH = 5, and uniformly 5 Kg of hydrogenated silicon oil with a hydrogen content of 0.8% was added dropwise, stirred for 8 hours after the addition, then cooled and filtered to obtain hydrogenated silicon oil-modified nano silicon dioxide. The hydrogenated silicone oil-modified nano-silica can be used as a rheology modifier for water-based coatings. The addition amount is 1%, the high-shear viscosity of the coating is obviously increased, the fluidity is improved under low shear, and it has good splash resistance. Leveling; at the same time, the surface hydrophobicity, stain resistance, weather resistance and corrosion resistance have all been significantly improved.

Embodiment 2

[0018] The formula and processing technology are as follows:

[0019] Add 60Kg of nano-silica sol to be treated and 0.02Kg of water-soluble metal salt cobalt naphthenate in a sealed kettle with a stirring and heating device, start stirring, drop into 0.15Kg NN-dimethylethanolamine pH regulator to adjust pH=6, and At 50°C, 6Kg of hydrogenated silicone oil with a hydrogen content of 0.6% was evenly added dropwise, stirred for 6 hours after the addition, then cooled and filtered to obtain hydrogenated silicone oil-modified nano-silica. The hydrogenated silicone oil-modified nano-silica can be used as a rheology modifier for water-based coatings. The addition amount is 1%, the high-shear viscosity of the coating is obviously increased, the fluidity is improved under low shear, and it has good splash resistance. Leveling; at the same time, the surface hydrophobicity, stain resistance, weather resistance and corrosion resistance have all been significantly improved.

Embodiment 3

[0021] The formula and processing technology are as follows:

[0022] Add 70Kg of nano-silica sol to be treated and 0.1Kg of water-soluble metal salt cobalt octanoate into a sealed kettle with a stirring and heating device, start stirring, add 0.2Kg diethanolamine and 0.05Kg phosphoric acid to adjust pH = 6, and drop evenly at 50°C Add 8Kg of hydrogenated silicon oil with a hydrogen content of 0.8%, stir for 6 hours after the addition, then cool and filter to obtain hydrogenated silicon oil-modified nano silicon dioxide. The hydrogenated silicone oil-modified nano-silica can be used as a rheology modifier for water-based coatings. The addition amount is 1%, the high-shear viscosity of the coating is obviously increased, the fluidity is improved under low shear, and it has good splash resistance. Leveling; at the same time, the surface hydrophobicity, stain resistance, weather resistance and corrosion resistance have all been significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com