Electrospinning dressing loading growth factor small molecule inhibitor, preparation method and applications thereof

A technology of small molecule inhibitor and growth factor, applied in the field of medical biology, can solve the problems of cumbersome preparation process, complex composition, inability to achieve slow release, etc., and achieve the effect of good hydrophilicity and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

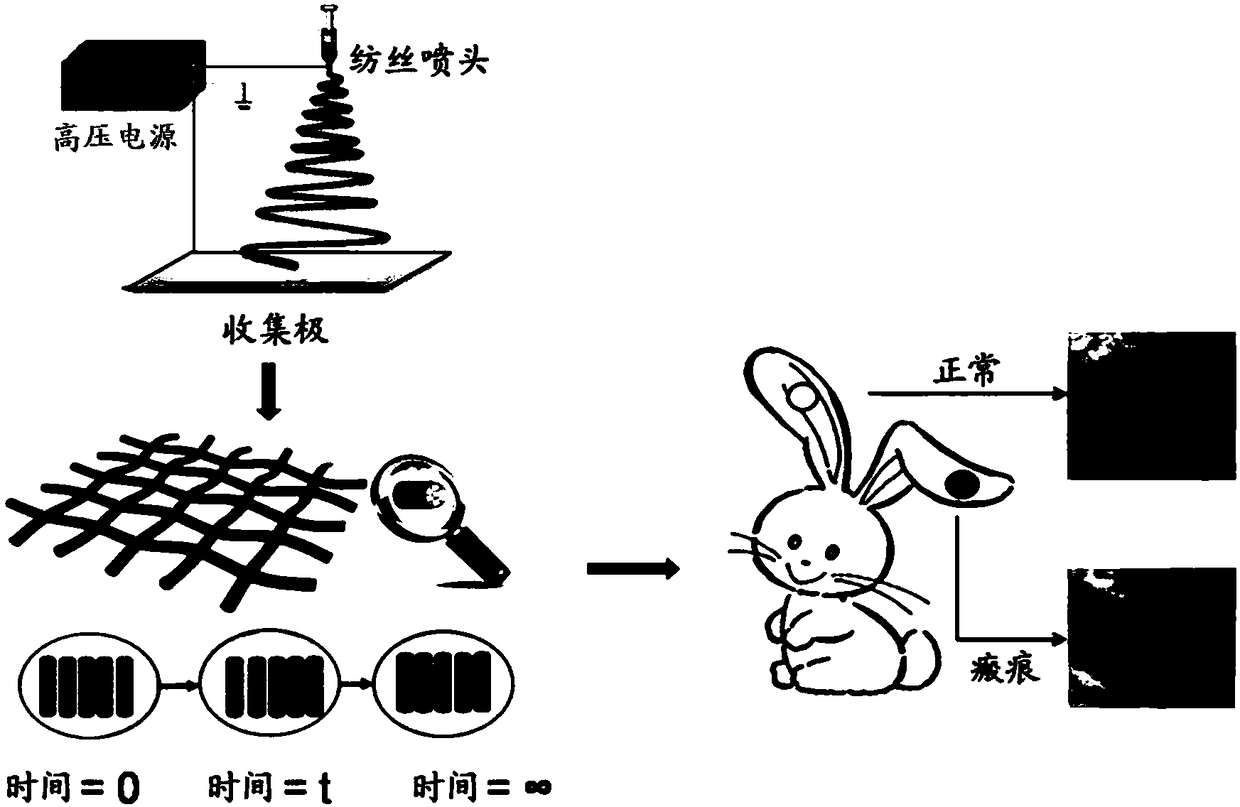

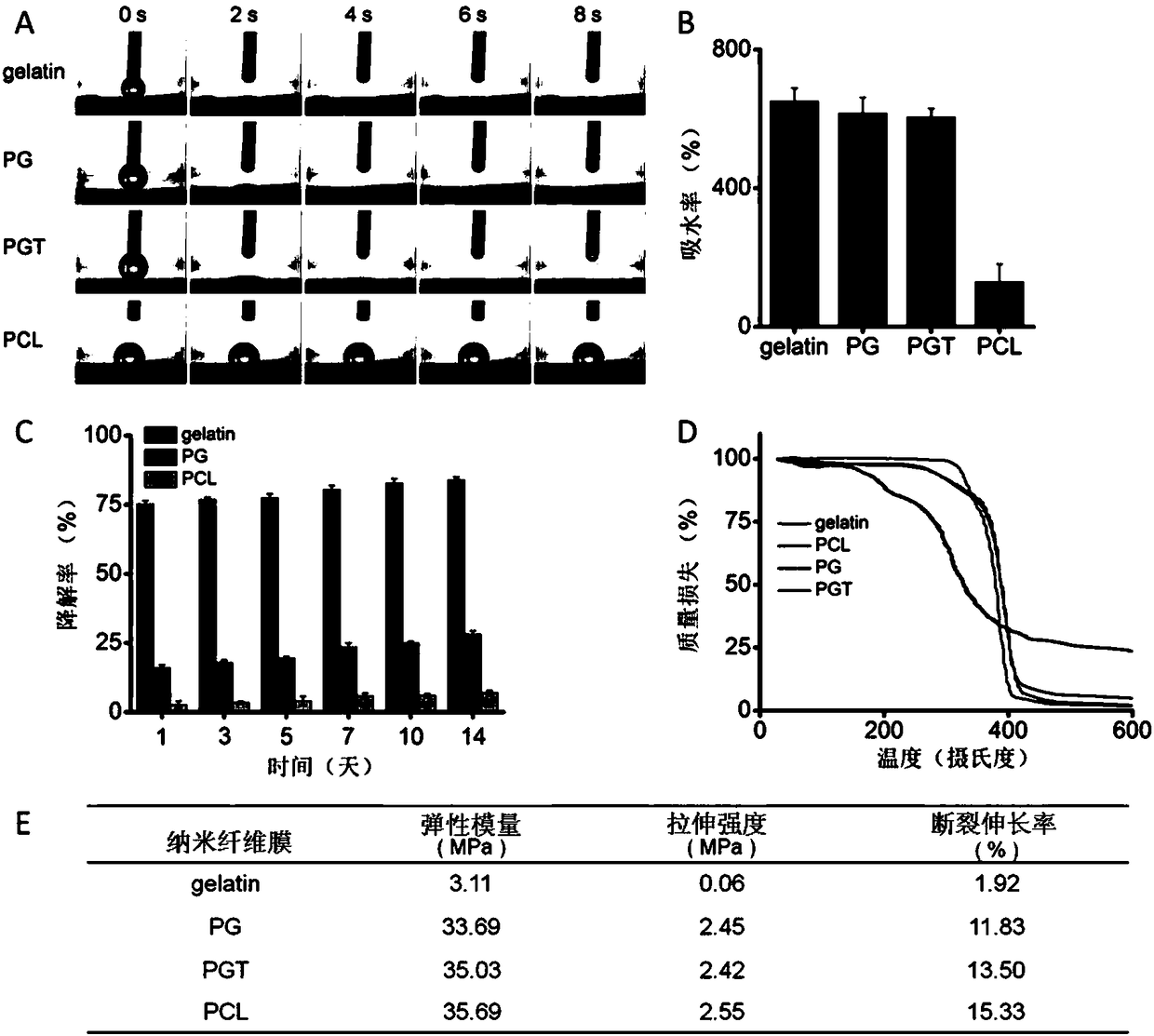

[0071] The device figure of the present invention design is as figure 1 shown. The spinning process is illustrated below by specific examples, and the steps are as follows:

[0072] (1) In a Erlenmeyer flask, 0.75 g of polycaprolactone (PCL, molecular weight 80000, Sigma), 0.25 g of gelatin (gelatin, type A powder, from pig skin, Sigma) and 5 ml of 5 μM l TGF-β1 inhibitor (TGF-β inhibitor, 6-[2-tert-butyl-5-(6-methyl-pyridin-2-yl)-1H-imidazol-4-yl]-quinoxalin, SB525334, Selleck Chemicals ), added 10 ml of hexafluoroisopropanol (1,1,1,2,2,2-Hexafluoro-2-propanol, HFIP, Sigma), and stirred for 2 hours at room temperature with a magnetic stirrer to make PCL, gelatin and TGF-β1 inhibitor were dissolved in HFIP and mixed uniformly to prepare a transparent spinning precursor solution.

[0073] (2) Inhale the configured electrospinning precursor solution into a syringe fixed on the propulsion pump, and the propulsion rate of the propulsion pump is 1.2 milliliters / hour and keep the...

Embodiment 2

[0078] Proceed as follows:

[0079] (1) In an Erlenmeyer flask, mix 1.2 grams of polylactic-co-glycolic acid (PLGA, 50 / 50, 12000, Sigma), 0.3 grams of collagen (type I, Sigma) and 5 milliliters of 5 μmol / L The TGF-β1 inhibitor was added into 10 ml of hexafluoroisopropanol, stirred at room temperature with a magnetic stirrer for 2 hours, so that PLGA and collagen were dissolved in HFIP and mixed evenly, and prepared into a transparent spinning precursor solution.

[0080] (2) The spinning process is the same as in Example 1.

[0081] (3) The performance characterization of the composite fiber membrane is the same as in Example 1, such as Figure 5 shown.

Embodiment 3

[0083] Proceed as follows:

[0084] (1) In a Erlenmeyer flask, add 1.0 grams of PLGA, 0.5 grams of gelatin and 5 milliliters of 5 micromole / liter TGF-β1 inhibitor into 10 milliliters of hexafluoroisopropanol, and use a magnetic stirrer at room temperature Under stirring for 2 hours, PLGA and gelatin were dissolved in HFIP and mixed uniformly to prepare a transparent spinning precursor solution.

[0085] (2) The spinning process is the same as in Example 1.

[0086] (3) The performance characterization of the composite fiber membrane is the same as in Example 1, such as Image 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com