Multi-arc coating film electroplating primer paint

A primer and resin technology, which is applied in the field of multi-arc coating electroplating primer and its preparation, can solve the problems of insoluble coating stability, poor performance, and resistance to salt spray, etc., and achieve environmental stability and durability Outstanding, good adhesion, environmental stability, and outstanding boiling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The second aspect of the present invention provides a kind of preparation method of multi-arc coating electroplating primer, at least comprises the following steps:

[0056] (1) Add epoxy acrylate resin, urethane acrylate resin, trimethylolpropane triacrylate, solvents with a boiling point range of 60-90°C, and solvents with a boiling point range of 120-160°C into the stirring tank in proportion Stir evenly, stir for 1-3 hours, and the stirring temperature is 20-50°C;

[0057] (2) Continue to add the main leveling agent, auxiliary leveling agent and initiator with an ultraviolet wavelength range of 300-400nm, and stir for 1-3 hours to obtain the multi-arc coating electroplating primer.

[0058] In some preferred embodiments, the preparation method of the multi-arc coating electroplating primer comprises the following steps:

[0059] (1) Add epoxy acrylate resin, urethane acrylate resin, trimethylolpropane triacrylate, solvents with a boiling point range of 60-90°C, and...

Embodiment 1

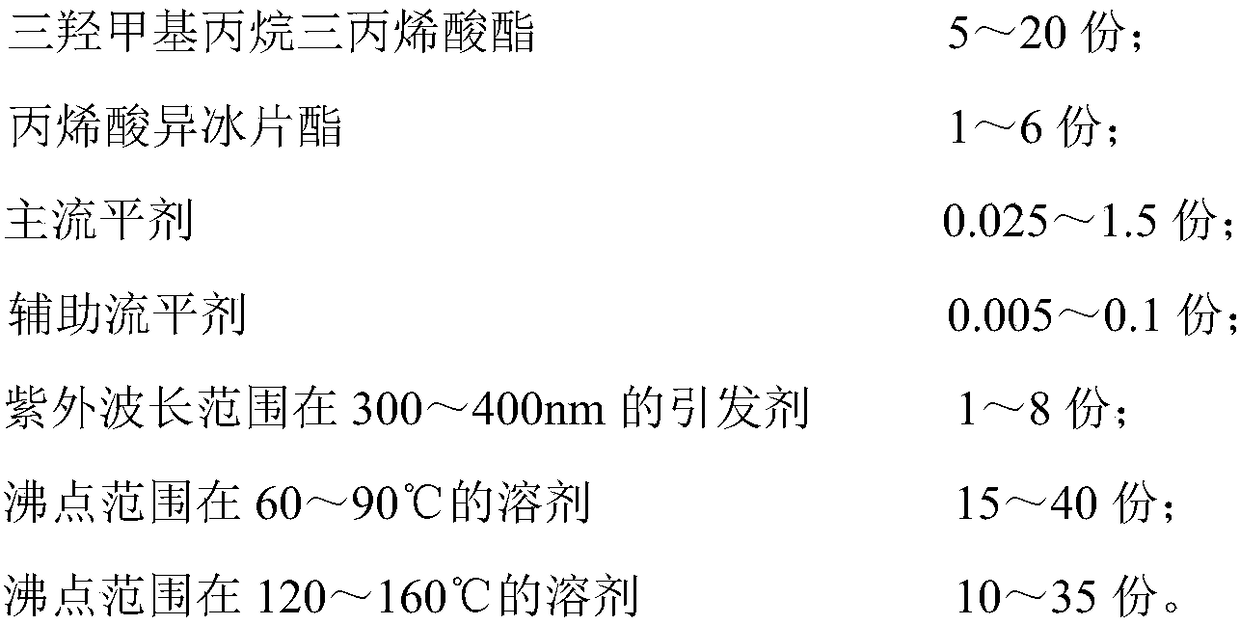

[0066] A kind of multi-arc coating electroplating primer, by weight, raw material comprises:

[0067]

[0068] In this embodiment, the main leveling agent is BYK333; the auxiliary leveling agent is TEGO-2100 leveling agent;

[0069] The initiator whose ultraviolet wavelength range is 300-400nm is a combination of 1-hydroxycyclohexyl phenyl ketone, benzyl dimethyl ether, and TPO photoinitiator, and its weight ratio is 1:1:1;

[0070] The solvent with a boiling point range of 60-90°C is ethyl acetate and butanone, and the weight ratio thereof is 0.5:1;

[0071] The solvent with a boiling point range of 120-160° C. is xylene and propylene glycol methyl ether acetate, and the weight ratio thereof is 1:1;

[0072] The preparation method of multi-arc coating electroplating primer comprises the following steps:

[0073] (1) Add epoxy acrylate resin, urethane acrylate resin, trimethylolpropane triacrylate, solvents with a boiling point range of 60-90°C, and solvents with a boilin...

Embodiment 2

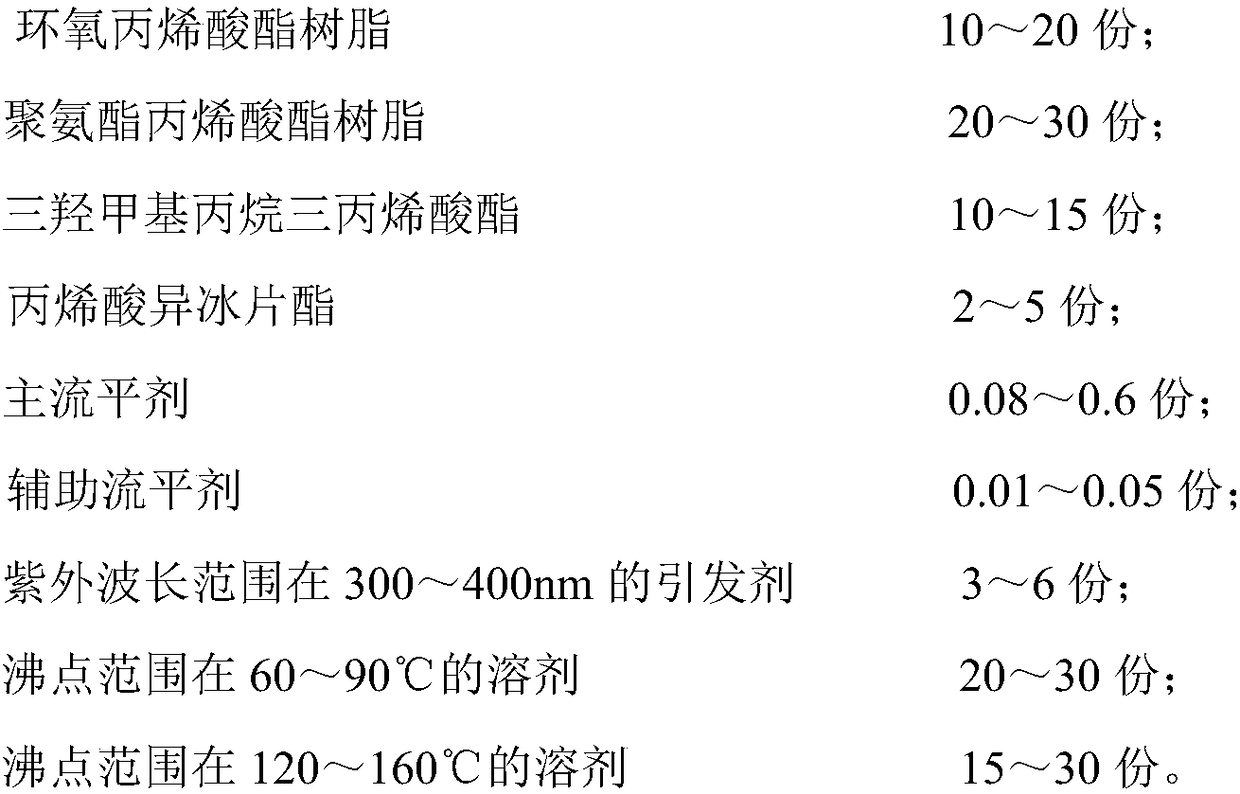

[0076] A kind of multi-arc coating electroplating primer, by weight, raw material comprises:

[0077]

[0078] In this embodiment, the main leveling agent is BYK333; the auxiliary leveling agent is TEGO-2100 leveling agent;

[0079] The initiator whose ultraviolet wavelength range is 300-400nm is a combination of 1-hydroxycyclohexyl phenyl ketone, benzyl dimethyl ether, and TPO photoinitiator, and its weight ratio is 2:1.5:1;

[0080] The solvent with a boiling point range of 60-90°C is ethyl acetate and butanone, and the weight ratio thereof is 1:1;

[0081] The solvent with a boiling point range of 120-160°C is xylene and propylene glycol methyl ether acetate, and the weight ratio thereof is 1.5:1;

[0082] The preparation method of multi-arc coating electroplating primer comprises the following steps:

[0083] (1) Add epoxy acrylate resin, urethane acrylate resin, trimethylolpropane triacrylate, solvents with a boiling point range of 60-90°C, and solvents with a boilin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com