Method for purifying crude sodium pyrophosphate to produce disodium hydrogen phosphate and sodium chloride

A technology of disodium hydrogen phosphate and sodium pyrophosphate, applied in chemical instruments and methods, phosphorus compounds, alkali metal chlorides, etc., can solve the problems of slow dissolution of crude sodium pyrophosphate, low device processing capacity and high sodium chloride content , to achieve the effect of reducing the amount of waste water produced, treating a large amount of water, and having a high treatment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

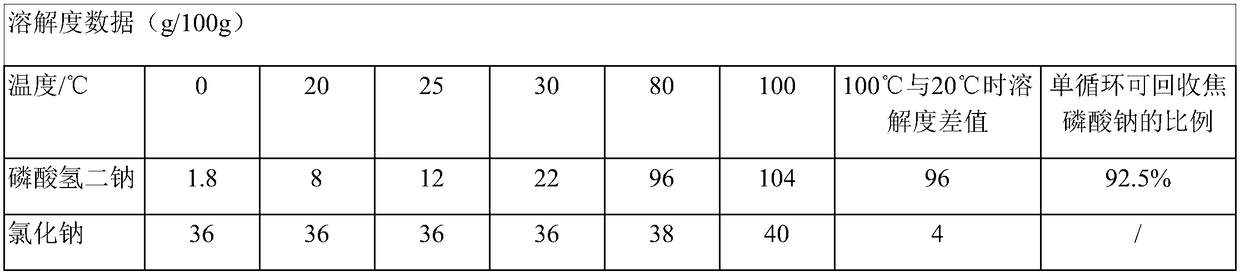

[0035] A method for purifying crude product sodium pyrophosphate to produce disodium hydrogen phosphate and sodium chloride, comprising the steps:

[0036] 1. Ingredients: During the initial start-up, mix the crude sodium pyrophosphate and water in the hydrolysis tank (hydrolysis tank) according to the mass ratio of 1:1, and add phosphoric acid dropwise to control the pH value of the mixed material within the range of 7.0.

[0037] During continuous operation, mix the crude sodium pyrophosphate and mechanically applied process water (filtrate B2, washing solution A and other process water described in the implementation steps) in the hydrolysis kettle (hydrolysis tank) according to the mass ratio of 1:1, and add dropwise Phosphoric acid controls the pH value of the mixed material in the range of 7.0.

[0038] After the crude product sodium pyrophosphate is partially dissolved, add an oxidizing auxiliary agent to carry out oxidation and sol reaction in the hydrolysis kettle (hy...

Embodiment 2

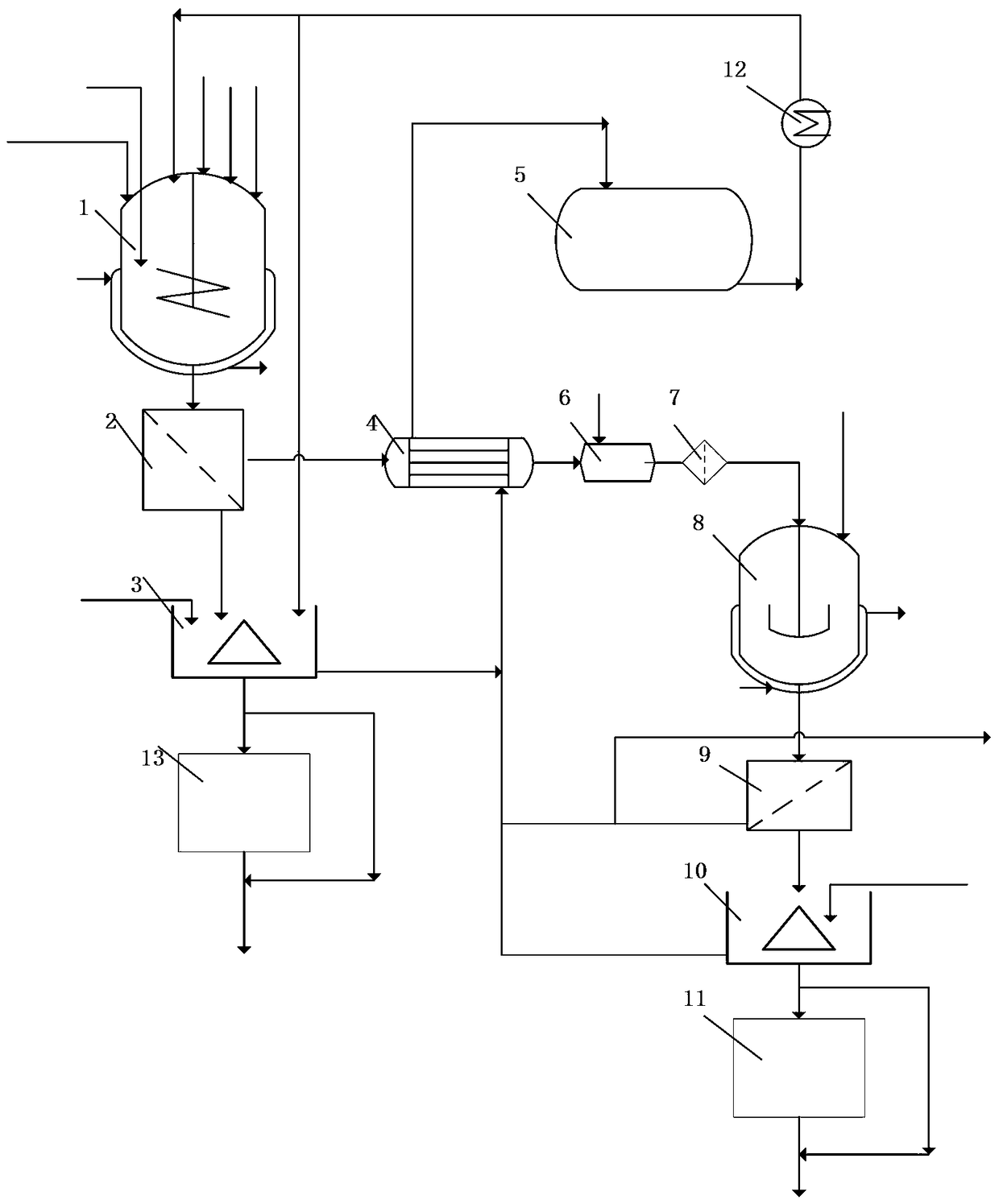

[0056] A device for purifying crude sodium pyrophosphate to produce sodium pyrophosphate and sodium chloride, the bottom of hydrolysis kettle 1 is connected to filter A2; filter device A2 is connected to heat exchanger 4, heat exchanger 4 is connected to mixer 6, and mixed Device 6 is connected to filter C 7, filter C 7 is connected to crystallization kettle 8, crystallization kettle 8 is connected to filter B 9, filter B 9 is connected to material washing device B 10, and material washing device B 10 is connected to pyrophosphoric acid Sodium deep refining device 11.

[0057] The filter B 9 and the material washing device B 10 are respectively connected to the heat exchanger 4 through pipelines, and the heat exchanger 4 is connected to the heater 12 through the water storage tank 5, and the heater 12 is connected to the hydrolysis kettle 1.

[0058] The bottom of the filter A 2 is connected to the material washing device A 3 through a pipeline, and the material washing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com