Water-holding controlled-release biological compound fertilizer and preparation method thereof

A compound fertilizer and biological technology, applied in the direction of urea compound fertilizer, organic fertilizer, ammonium salt fertilizer, etc., to achieve the effect of reducing heavy metal content, excellent granulation performance and compressive strength, and improving soil structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

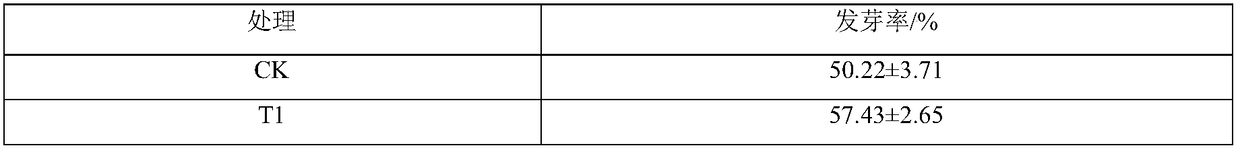

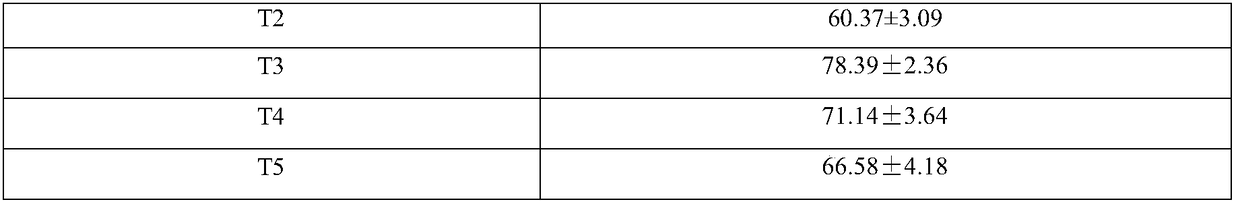

Examples

Embodiment 1

[0026] A water-retaining and controlled-release biological compound fertilizer, which is composed of the following raw materials in parts by weight: 20 parts of biomass charcoal, 0.06 parts of sodium lauryl sulfate, 0.02 parts of polyvinylpyrrolidone, 10 parts of humic acid powder, and 4 parts of medical stone powder 1 part, 8 parts of urea, 0.05 part of 2-mercaptobenzoic acid, 6 parts of modified starch adhesive, 12 parts of acrylic acid, 0.1 part of benzoin dimethyl ether, 1 part of ammonium persulfate, 7 parts of fermented organic fertilizer, 1 part of microbial powder share.

[0027] Further, the biochar is prepared by high-temperature cracking of corn stalks at 450° C. under anoxic conditions, and the particle size is 1.0-2.0 mm.

[0028] Further, the fermented organic fertilizer uses pig manure as a raw material, corn stalks as a conditioning agent, adjusts the water content, adds biochar, mixes uniformly, prepares by aeration and oxygen supply fermentation, and pulveriz...

Embodiment 2

[0036] A water-retaining and controlled-release biological compound fertilizer, which is composed of the following raw materials in parts by weight: 25 parts of biomass charcoal, 0.07 parts of sodium lauryl sulfate, 0.03 parts of polyvinylpyrrolidone, 15 parts of humic acid powder, and 6 parts of medical stone powder 11 parts of urea, 0.1 part of 2-mercaptobenzoic acid, 9 parts of modified starch adhesive, 18 parts of acrylic acid, 0.2 parts of benzoin dimethyl ether, 2 parts of ammonium persulfate, 9 parts of fermented organic fertilizer, 4 parts of microbial powder share.

[0037] Further, the biochar is prepared by high-temperature cracking of corn stalks at 450° C. under anoxic conditions, and the particle size is 1.0-2.0 mm.

[0038] Further, the fermented organic fertilizer uses pig manure as a raw material, corn stalks as a conditioning agent, adjusts the water content, adds biochar, mixes uniformly, prepares by aeration and oxygen supply fermentation, and pulverizes af...

Embodiment 3

[0046] A water-retaining and controlled-release biological compound fertilizer, which is composed of the following raw materials in parts by weight: 35 parts of biomass charcoal, 0.08 parts of sodium lauryl sulfate, 0.05 parts of polyvinylpyrrolidone, 18 parts of humic acid powder, and 9 parts of medical stone powder 15 parts of urea, 0.2 parts of 2-mercaptobenzoic acid, 13 parts of modified starch adhesive, 22 parts of acrylic acid, 0.3 parts of benzoin dimethyl ether, 3 parts of ammonium persulfate, 16 parts of fermented organic fertilizer, 5 parts of microbial powder share.

[0047] Further, the biochar is prepared by high-temperature cracking of corn stalks at 450° C. under anoxic conditions, and the particle size is 1.0-2.0 mm.

[0048] Further, the fermented organic fertilizer uses pig manure as a raw material, corn stalks as a conditioning agent, adjusts the water content, adds biochar, mixes uniformly, prepares by aeration and oxygen supply fermentation, and pulverizes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com