A kind of preparation method of slump-retaining polycarboxylate superplasticizer mother liquor

A technology of water reducer and polycarboxylate, which is applied in the field of preparation of slump-preserving polycarboxylate water reducer mother liquor, which can solve the problems of dangerous use and low explosion limit, and achieve the effects of convenient transportation, good activity and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

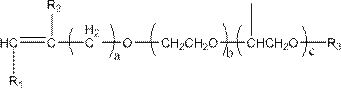

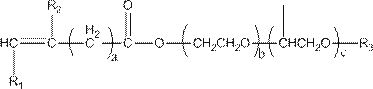

[0036]The present invention proposes a method for preparing a slump-preserving polycarboxylate superplasticizer mother liquor, which uses the by-product epoxy compound and polycarboxylate superplasticizer prepolymer in the production process of organosilane coupling agent to directly carry out Ring-opening esterification reaction (ring-opening esterification of carboxylic acid groups and epoxy groups) to generate polycarboxylate superplasticizers, thereby adjusting the length and density of the side chains of polycarboxylate superplasticizers, giving polycarboxylate water-reducing agents The effect of anti-slump agent, in which organosilane coupling agent includes but not limited to γ-(2,3-epoxypropoxy)hydrocarbyl silane coupling agent including KH560, also includes γ-(2,3-epoxy Propoxy)-Propyltriethoxysilane, γ-(2,3-Glycidoxy)-Propylmethyldimethoxysilane, γ-(2,3-Glycidoxy)-Propyl Methyldiethoxysilane. When producing these organosilane coupling agents, the by-products used fo...

Embodiment 1

[0054] (1) Preparation of polycarboxylate superplasticizer prepolymer: 0.082mol 3-methyl-3-butyl-1-polyethylene glycol (2500g / mol) and 0.115mol acrylic acid in unsaturated polyether monomer Under the action of 0.00082mol ammonium persulfate, 0.00246mol ferrous sulfate and 0.00082mol mercaptoacetic acid, keep 80°C for water phase free radical polymerization for 3 hours to obtain polycarboxylate superplasticizer prepolymer;

[0055] (2) Preparation method of slump-preserving polycarboxylate water reducer: add 23.65g (a total of 0.19mol epoxy compound) of the by-product epoxy compound in the industrial production process of organosilane coupling agent KH560 to the polycarboxylate pre- Polymer (based on carboxyl content of 0.29mol) carries out epoxy ring-opening esterification reaction with carboxyl group, wherein the molar ratio of carboxyl group contained in polycarboxylic acid prepolymer to by-product epoxy compound is 1.54, and the reaction temperature is kept at 80 ℃ for two ...

Embodiment 2

[0057] (1) Preparation of polycarboxylate superplasticizer prepolymer: 0.082mol 3-methyl-3-butyl-1-polyethylene glycol (2500g / mol) and 0.31mol acrylic acid in unsaturated polyether monomer Under the action of 0.0028mol ammonium persulfate, 0.0012mol ferrous sulfate and 0.0074mol mercaptoacetic acid, keep 60°C for water phase free radical polymerization for 4.5 hours to obtain polycarboxylate superplasticizer prepolymer;

[0058] (2) Preparation method of slump-preserving polycarboxylate water reducer: add 23.65g (a total of 0.19mol epoxy compound) of the by-product epoxy compound in the industrial production process of organosilane coupling agent KH560 to the polycarboxylate pre- Polymer (based on carboxyl content of 0.31mol) carries out epoxy ring-opening esterification reaction with carboxyl group, wherein the molar ratio of carboxyl group contained in polycarboxylic acid prepolymer to by-product epoxy compound is 100:62, keep the reaction temperature At 85°C for two hours, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com