Preparation method and application of polyphosphazene modified black phosphorene

A technology of black phosphorene and polyphosphazene, applied in the field of black phosphorus, can solve the problems of poor compatibility and difficult dispersion, and achieve the effect of improving the flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] First, mix 500mg red phosphorus, 120mg tin powder and 30mg tin iodide according to a certain ratio, put them into a mortar, crush and mix them evenly, then seal the tube, and encapsulate the above mixed powder into a certain size ( length 10cm×diameter 1cm), then place the above-mentioned quartz tube in the tube of the tube furnace, conduct heat treatment under the condition of feeding nitrogen throughout the whole process, raise the temperature from normal temperature to 650°C, keep it for a period of time and then cool it down to 500°C , keep it for a period of time, and then drop to room temperature. After the furnace cools down, take out the black phosphorus crystal block from the quartz tube, wash the sample with hot toluene to remove the residual mineralizer, and then obtain a high-purity black phosphorus crystal block.

[0049] Disperse the black phosphorous crystal block in N-methylpyrrolidone (NMP) at a concentration of 1 mg / mL for 10 h and ultrasonically peel i...

Embodiment 2

[0055] Into a 250mL three-neck flask equipped with a mechanical stirrer, a reflux condenser, a constant pressure dropping funnel, and a nitrogen inlet, add 1g of black phosphorene, 0.505g of 4,4'-diaminodiphenyl ether, 0.672g of tris Ethylamine and 125mL acetonitrile were mixed ultrasonically for 30min, then hexachlorocyclotriphosphazene (0.268g) / acetonitrile solution (100mL) was added dropwise under nitrogen atmosphere and room temperature, and ultrasonically reacted for 30min, then the above device was transferred to an oil bath Heated to 75°C for reflux reaction for 6-10h, centrifuged the dark brown reaction solution at 8000rpm, washed the obtained precipitate with ethanol and deoxygenated water three times to obtain a dark brown product, and placed it in a vacuum oven at 60°C dry.

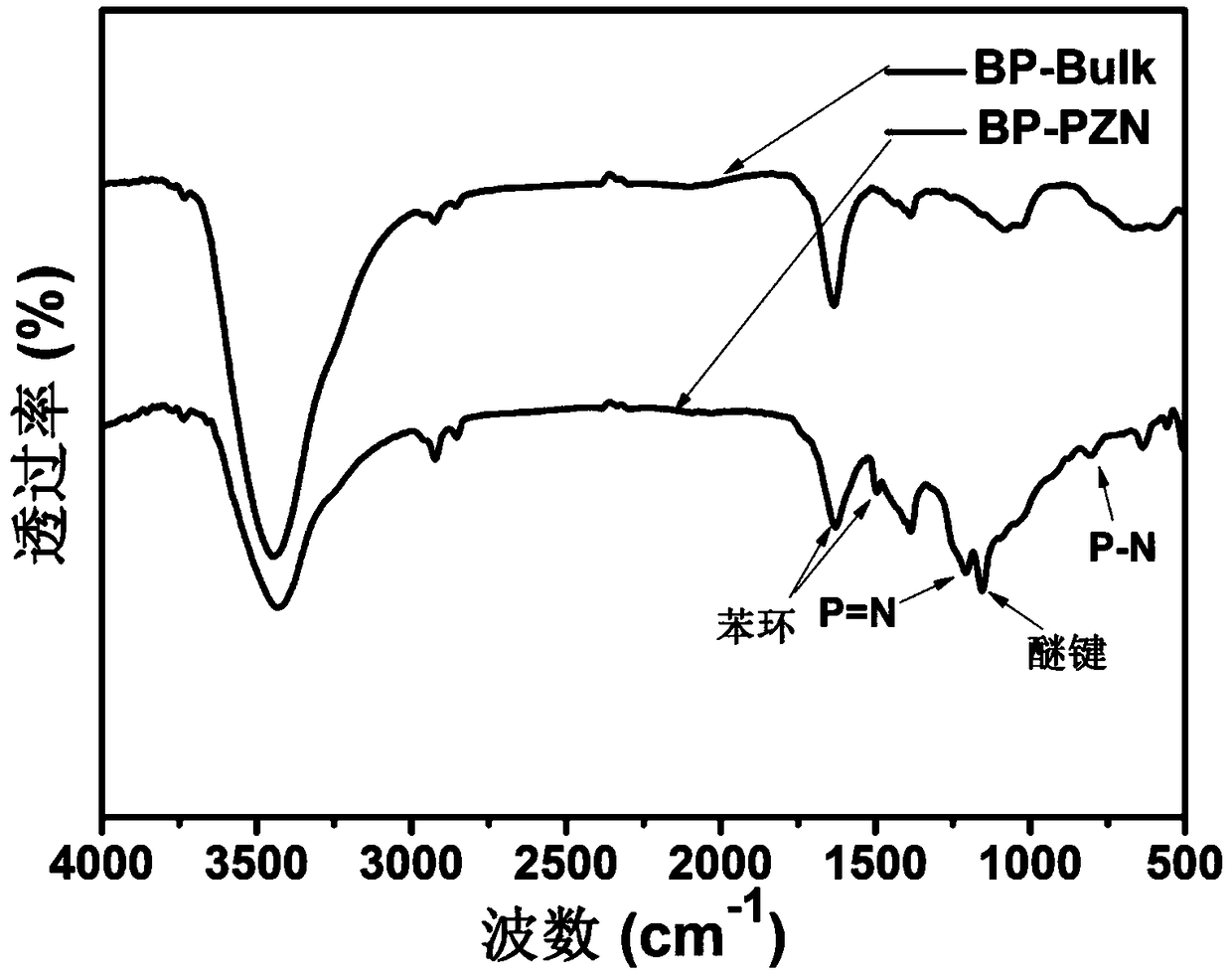

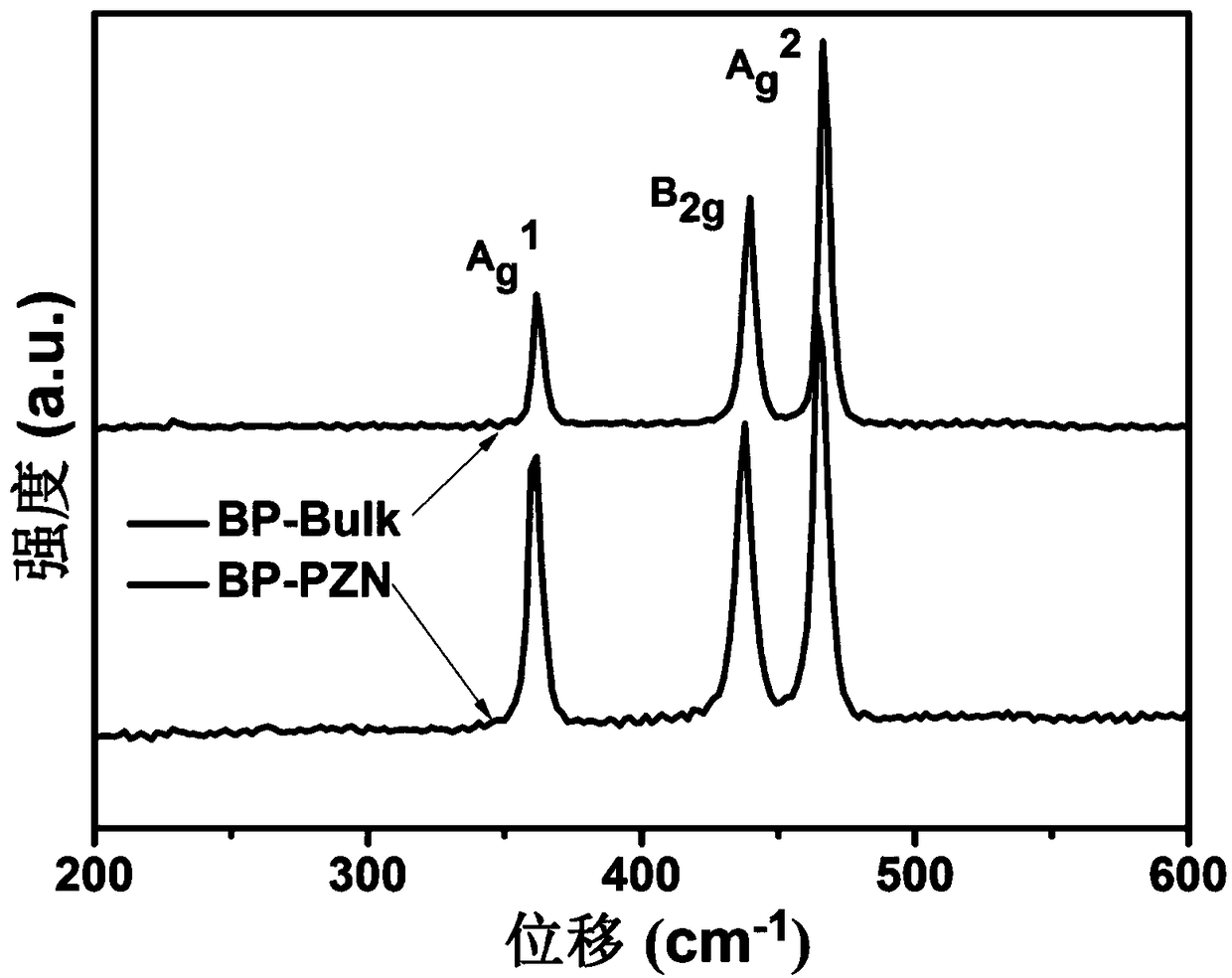

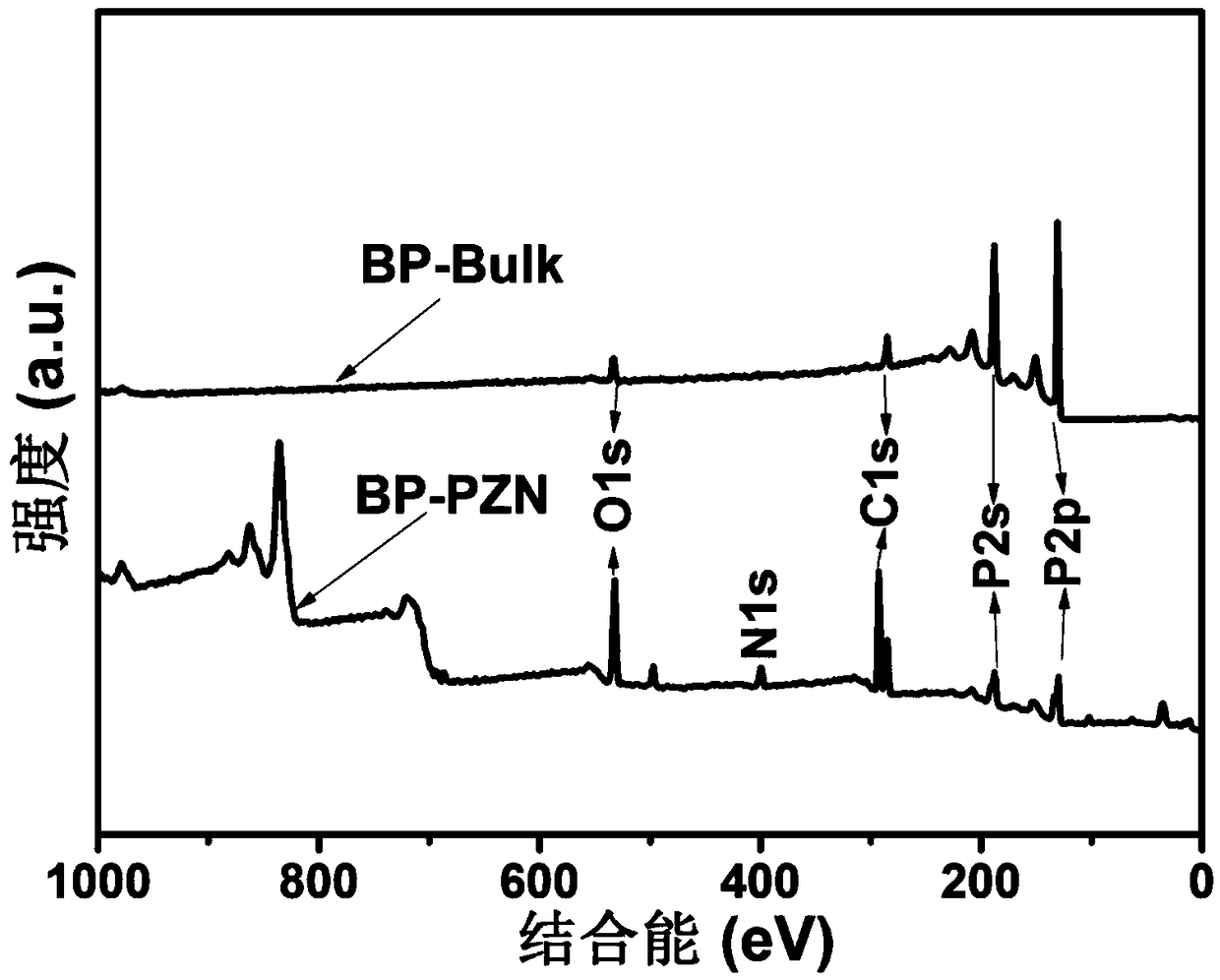

[0056] Infrared, Raman and XPS analysis are carried out to gained dark brown product, wherein, figure 1 Infrared spectra of black phosphorene provided in Example 1 and Example 2 of the present...

Embodiment 3

[0058] Disperse 0.225g of the black phosphorene obtained in Example 2 in acetone, add it into 36.76g of epoxy resin oligomer E-44 (epoxy value 0.44mol / 100g) dissolved in 20mL of acetone, and ultrasonically stir evenly, and evenly disperse Finally, place it in an oil bath to evaporate the solvent, then add the curing agent 4,4'-diaminodiphenylmethane, then pour it into a mold of 10cm×10cm×3mm and cure it at 100°C for 2 hours, then raise the temperature to 150°C and cure it for 2 hours to obtain the modified Composite materials with 0.5wt% added black phosphorene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com