A PVDF-based composite material with sea-island structure and its preparation method

A technology of composite material and sea-island structure, which is applied in the field of PVDF-based composite material with sea-island structure and its preparation, can solve the problems of high dielectric constant and low dielectric loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

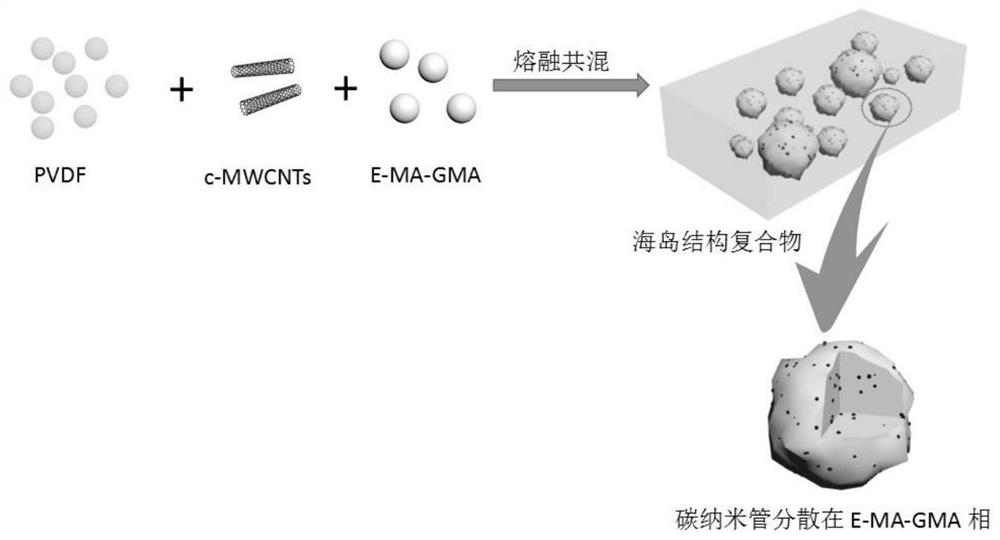

[0025] The present invention also provides a method for preparing a PVDF-based composite material with a sea-island structure, the process schematic diagram of the composite material and the sea-island structure schematic diagram of the composite material are as follows figure 1 As shown, the method includes:

[0026] Step 1: Put polyvinylidene fluoride, ethylene-methyl acrylate-glycidyl methacrylate and carbon nanotubes into a torque rheometer for melt blending to obtain polyvinylidene fluoride / ethylene-methyl acrylate- Glycidyl methacrylate / carbon nanotube composite;

[0027] Step 2: Put the polyvinylidene fluoride / ethylene-methyl acrylate-glycidyl methacrylate / carbon nanotube composite in step 1 into a mold for hot pressing, and then transfer to a cold press for cold pressing until the mold is cooled Below the deformation temperature of PVDF, the PVDF-based composite material with sea-island structure is obtained by demoulding.

[0028] According to the present invention,...

Embodiment 1

[0034] Polyvinylidene fluoride, ethylene-methyl acrylate-glycidyl methacrylate and carbon nanotubes were put into a torque rheometer at a mass ratio of 88:10:2 for melt blending, and the blending temperature was 200°C. The rotor speed is 60 rpm, and the blending time is 5 minutes to obtain polyvinylidene fluoride / ethylene-methyl acrylate-glycidyl methacrylate / carbon nanotube composite;

[0035] Put the polyvinylidene fluoride / ethylene-methyl acrylate-glycidyl methacrylate / carbon nanotube composite in a mold, heat it to 200°C, press it under a pressure of 10MPa for 5 minutes, and keep it under pressure until The mold is cooled to below the PVDF deformation temperature for demoulding to obtain a composite material.

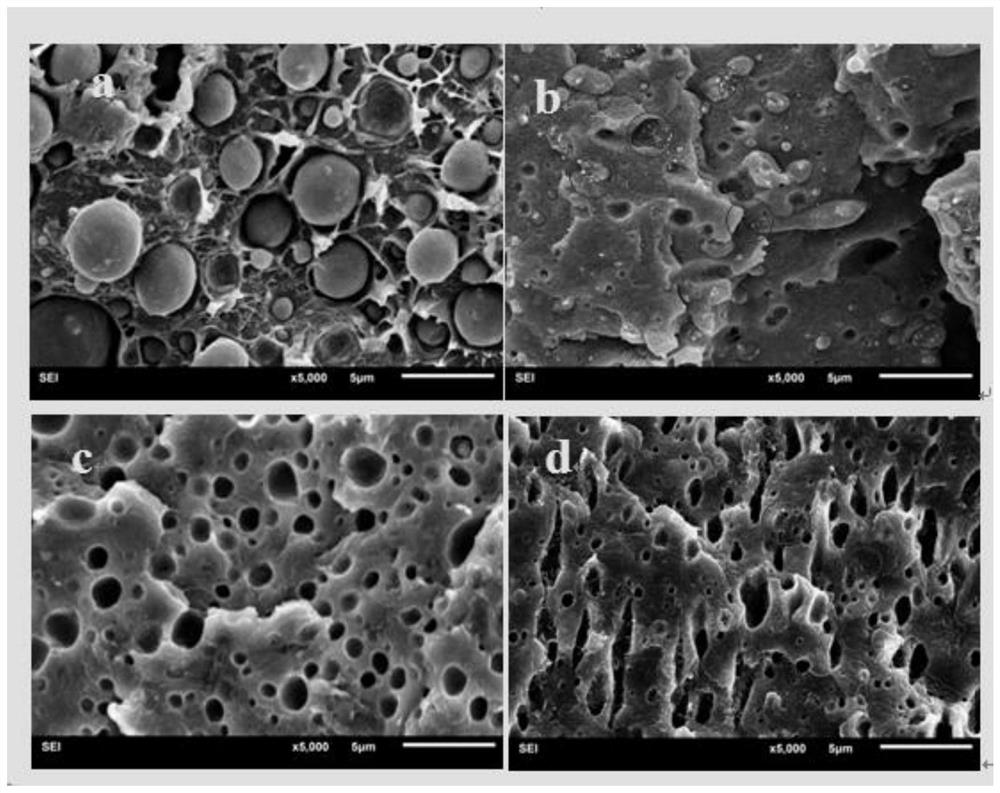

[0036] figure 2 It is the scanning electron microscope picture of the composite material that is made in embodiment 1; Wherein, (a) is the image when not adding carbon nanotube; (b) is the image when carbon nanotube mass fraction is 2wt%; (c), (d) corresponds to ...

Embodiment 2

[0039] The steps and conditions are the same as in Example 1, except that polyvinylidene fluoride, ethylene-methyl acrylate-glycidyl methacrylate and carbon nanotubes are added in a mass ratio of 89:10:1.

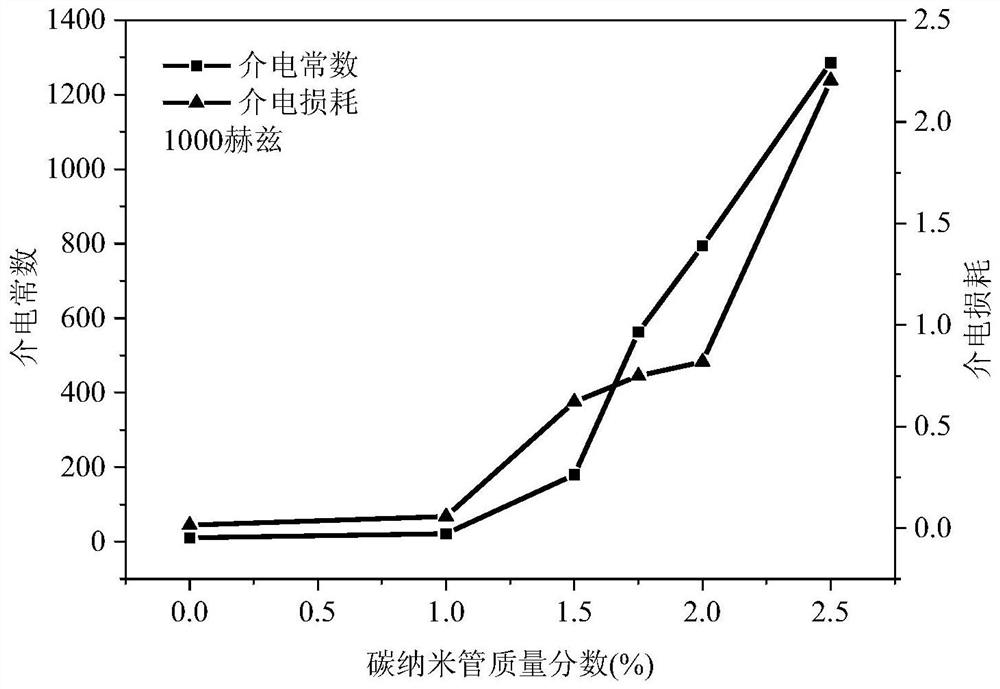

[0040] The obtained composite material permittivity and dielectric loss of embodiment 2 are obtained by alternating current impedance meter test, and its result is as follows image 3 As shown, the dielectric constant of the material is 22 at 1000 Hz, and the dielectric loss is 0.057 at this time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com