Energy-saving type acetic acid or ethyl acetate hydrogenation ethyl alcohol production process and device

A technology for producing ethyl acetate and a production process, which is applied in the production process and device field of ethanol by hydrogenation of acetic acid or ethyl acetate. The effect of reduced equipment investment, simple process, and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

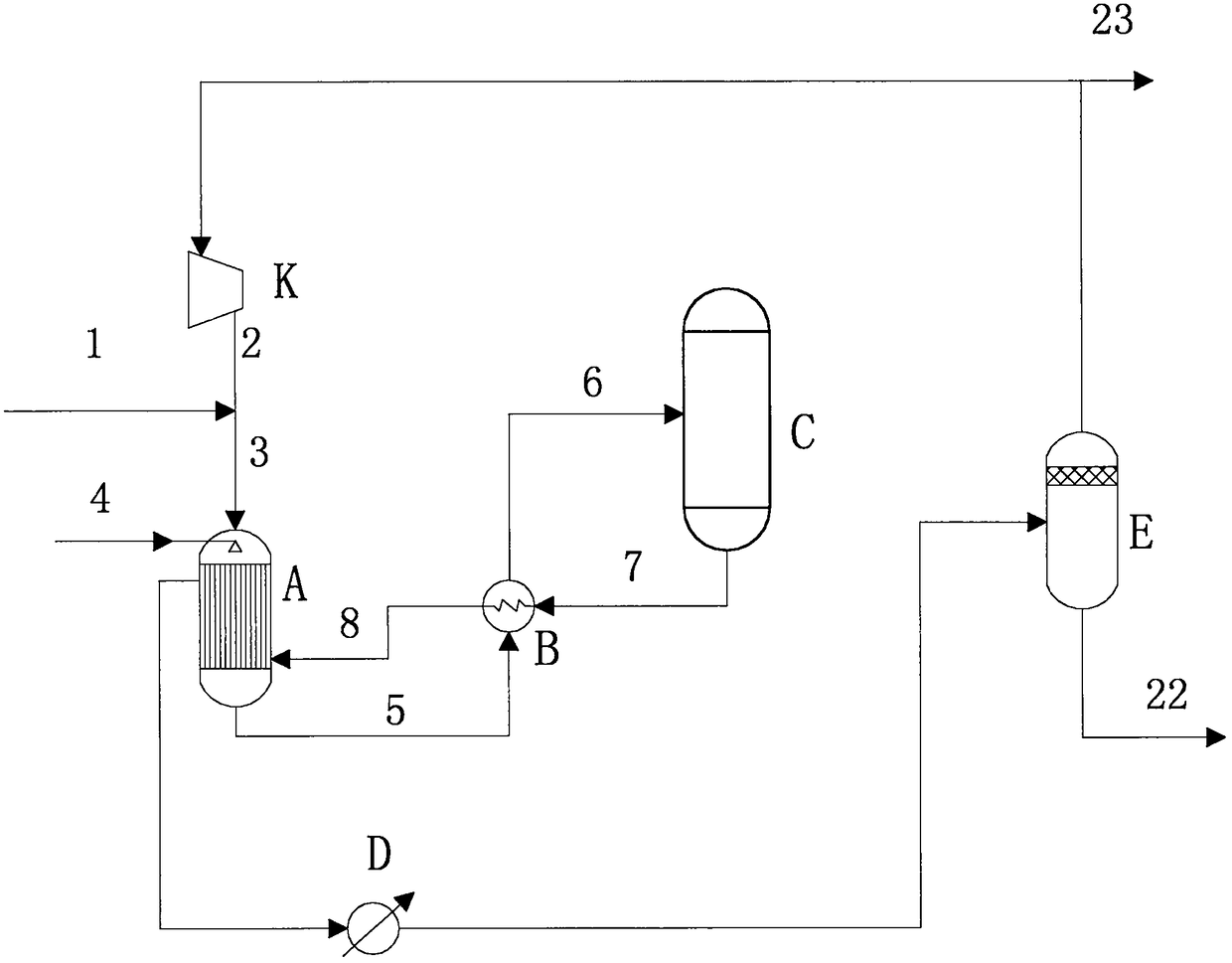

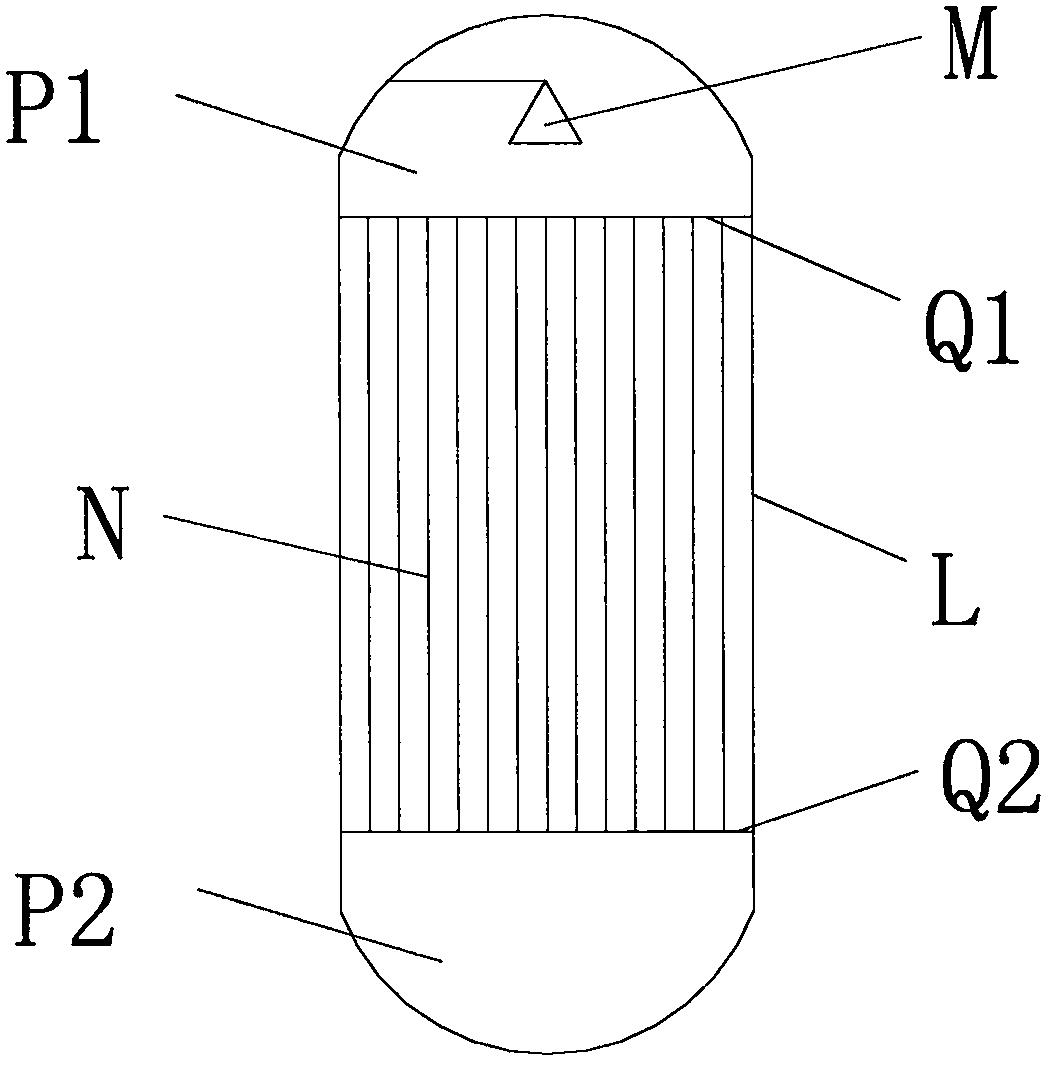

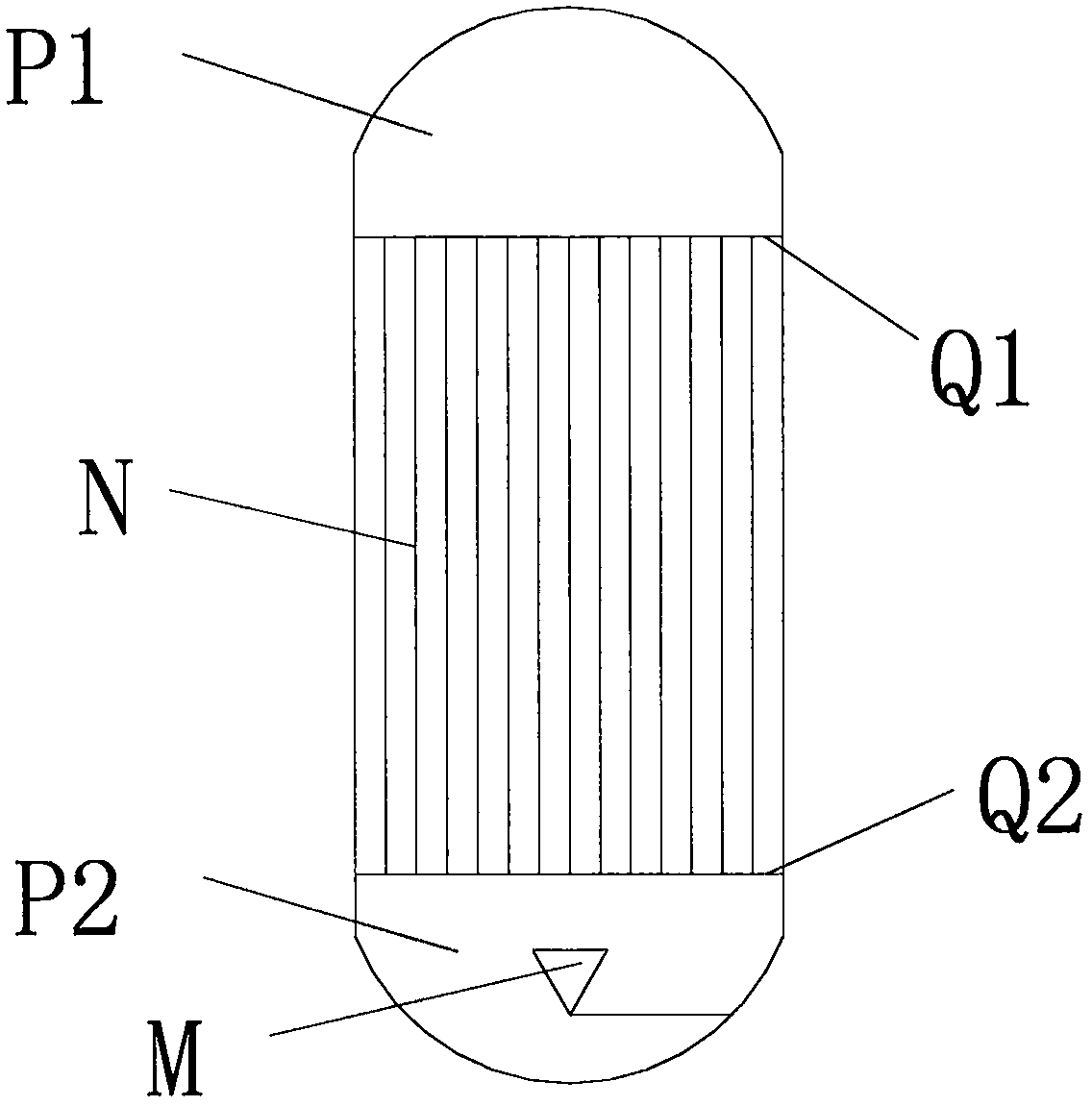

[0043] like figure 1 The energy-saving production device of the hydrogenation of acetic acid or hydrogenation of ethyl acetate to ethanol production process includes the first heating vaporizer A, the first tower gas preheater B, the first hydrogenation reactor C, The first cooler D, the first gas-liquid separator E and the cycler K, the outlet of the cycler K is communicated with the tube side inlet of the first heating vaporizer A, and the tube side outlet of the first heating vaporizer A is connected with The shell side inlet of the first tower gas preheater B is connected, the shell side outlet of the first tower gas preheater B is connected with the inlet of the first hydrogenation reactor C, and the first hydrogenation reactor The outlet of the reactor C is communicated with the tube-side inlet of the first tower-entry gas preheater B, and the tube-side outlet of the first tower-entry gas preheater B is communicated with the shell-side inlet of the first heat vaporizer A...

Embodiment 2

[0047] Taking acetic acid as an example of an ethanol synthesis device with an annual output of 1 million tons, the annual operation is 8,000 hours, and the hourly consumption of H 2 Volume 122500~125000Nm 3 / h, the total consumption of acetic acid is 164~171t / h, and the total amount of synthetic catalyst is ~200m 3 . like Figure 4 As shown, the ethanol synthesis device includes two hydrogenation reactor units connected in series, each hydrogenation reactor unit includes a heating vaporizer, a tower preheater, a hydrogenation reactor and a gas-liquid separation unit connected in series with an inlet and outlet pipeline. device. like Figure 1 As shown, the gas outlet of the first gas-liquid separator E in the first hydrogenation reactor unit communicates with the inlet pipeline of the second vaporization heater F in the second hydrogenation reactor unit, and the inlet of the circulator K is It is connected with the gas outlet of the second gas-liquid separator J, the out...

Embodiment 3

[0053] Taking ethyl acetate as an example of an ethanol plant with an annual output of 1 million tons, the annual operation is 8,000 hours, and the hourly consumption of H 2 Volume 61000~63000Nm 3 / h, the total ethyl acetate flow rate consumed is 120-125t / h, and the total amount of synthetic catalyst is 170-180m 3 . Device is the same as embodiment one.

[0054] Synthesis pressure 3.0-4.0MPa, all raw material hydrogen 1 at 40°C is mixed with 64°C cycle gas 2 at the outlet of cycler K, and the flow rate of cycle gas 2 is 440,000-510,000 Nm 3 / h, after mixing, the gas temperature is 63°C and a stream of liquid ethyl acetate with a total amount of ~50% at normal temperature is fully mixed in the first heating vaporizer A, and the moles of the mixed gas and ethyl acetate are controlled in the first heating vaporizer A Ratio 25~30:1, the molar ratio mainly comes from the catalyst requirements of ethyl acetate hydrogenation to ethanol, the mixed gas and liquid ethyl acetate are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com