Glimepiride tablet and preparation method thereof

The technology of glimepiride tablet and urea tablet is applied in the field of medicine and can solve the problems of glimepiride easily absorbing, sticky punching and splitting tablet, glimepiride tablet having low disintegration degree and being unsuitable for mass production, etc. Achieve the effect of increasing absolute bioavailability, conducive to disintegration and dissolution, and improving absolute bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

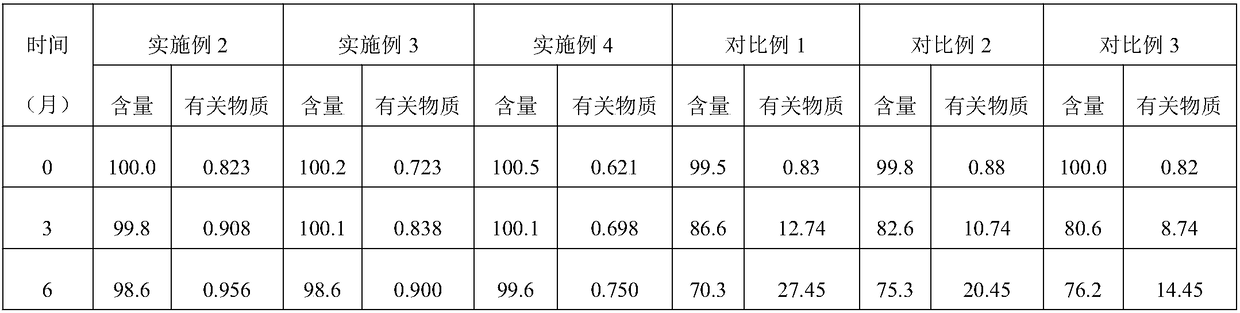

Examples

Embodiment 1

[0034] Embodiment 1, the preparation of glimepiride

[0035] S1: 3-ethyl-4-methyl-2-pyrrolidone is added in n-heptane, the mass ratio of 3-ethyl-4-methyl-2-pyrrolidone and n-heptane is 1:15, and the temperature is raised to Dissolve at 70-90°C, add phenylethyl isocyanate dropwise, the molar ratio of phenylethyl isocyanate to 3-ethyl-4-methyl-2-pyrrolidone is 1:1, heat to 90°C, react After 8 hours, it was lowered to room temperature to obtain a crude product of Compound A, and then added methyl tert-butyl ether equal in mass to n-heptane, stirred for 25 minutes, filtered, and dried to obtain a pure product of Compound A;

[0036] S2: Add the pure compound A prepared in step S1 to chlorosulfonic acid with a mass ratio of 2.8:1 to 3-ethyl-4-methyl-2-pyrrolidone, the reaction temperature is 20°C, stir for 2.5h, add 10 ℃ water, dry crystal, filter to obtain compound B;

[0037] S3: Add the compound B prepared in step S2 to 3-ethyl-4-methyl-2-pyrrolidone in saturated ammonia water...

Embodiment 2

[0039] Embodiment 2, a kind of glimepiride tablet

[0040] The glimepiride tablet comprises an immediate-release layer and a sustained-release layer:

[0041] The sustained-release layer is a hydroxypropyl-β-cyclodextrin inclusion compound, and the hydroxypropyl-β-cyclodextrin inclusion compound is composed of glimepiride and hydroxypropyl-β-cyclodextrin by weight Made with a ratio of 1:3;

[0042] The immediate-release layer is composed of the following components and parts by weight: 1 part of glimepiride, 10 parts of β-cyclodextrin, 20 parts of sodium hydroxymethyl starch, 10 parts of microcrystalline cellulose, 1 part of magnesium stearate 50 parts and lactose;

[0043] The particle size of the immediate-release layer β-cyclodextrin, sodium hydroxymethyl starch, microcrystalline cellulose, magnesium stearate and lactose is 10-90 μm;

[0044] The glimepiride is prepared from Example 1;

[0045] The weight ratio of glimepiride in the immediate-release layer and the susta...

Embodiment 3

[0049] Embodiment 3, a kind of glimepiride tablet

[0050] The glimepiride tablet comprises an immediate-release layer and a sustained-release layer:

[0051] The sustained-release layer is a hydroxypropyl-β-cyclodextrin inclusion compound, and the hydroxypropyl-β-cyclodextrin inclusion compound is composed of glimepiride and hydroxypropyl-β-cyclodextrin by weight Made with a ratio of 1:4;

[0052] The immediate-release layer is composed of the following components and parts by weight: 1 part of glimepiride, 10 parts of β-cyclodextrin, 20 parts of sodium hydroxymethyl starch, 10 parts of microcrystalline cellulose, and 1 part of magnesium stearate and lactose 50 parts.

[0053] The particle size of β-cyclodextrin, sodium hydroxymethyl starch, microcrystalline cellulose, magnesium stearate and lactose in the immediate release layer is 10-90 μm;

[0054] The glimepiride is prepared from Example 1;

[0055] The weight ratio of glimepiride in the quick-release layer and the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com