Nanofiber gel material with synergistic functions of pollutant adsorption, catalysis and fluorescence tracking and its preparation method

A nanofiber, gel material technology, applied in gel preparation, chemical instruments and methods, fiber chemical characteristics, etc., can solve the problems of poor processing performance, complex process, complex preparation process, etc., to improve strength, achieve protection, Good structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

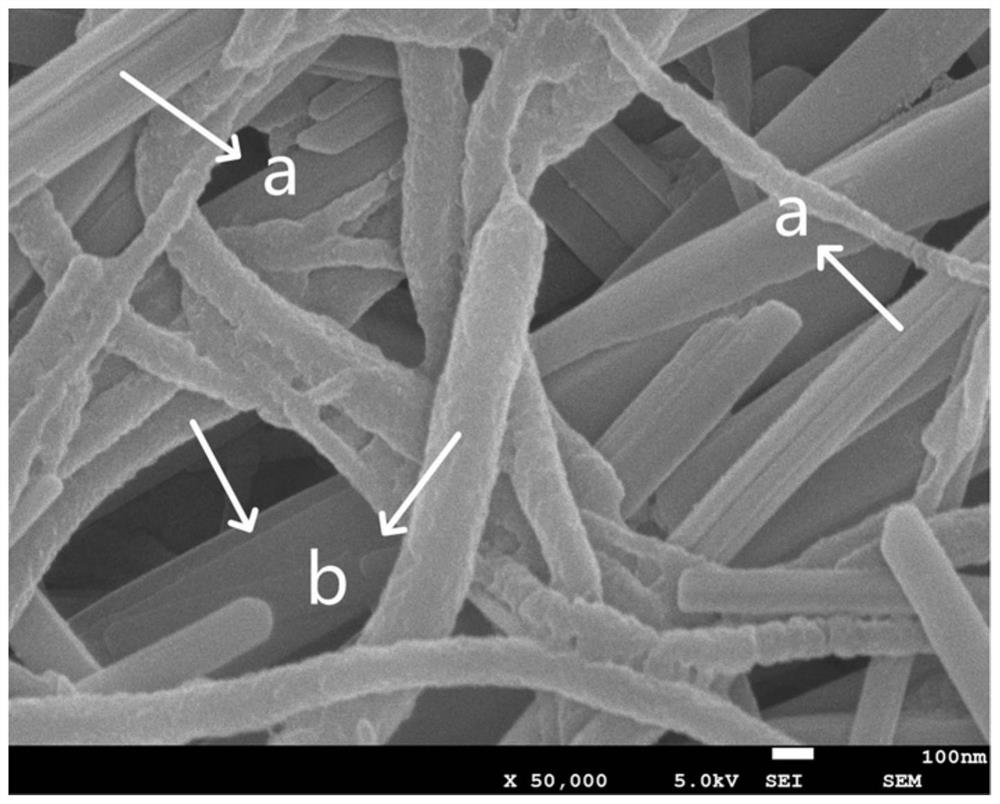

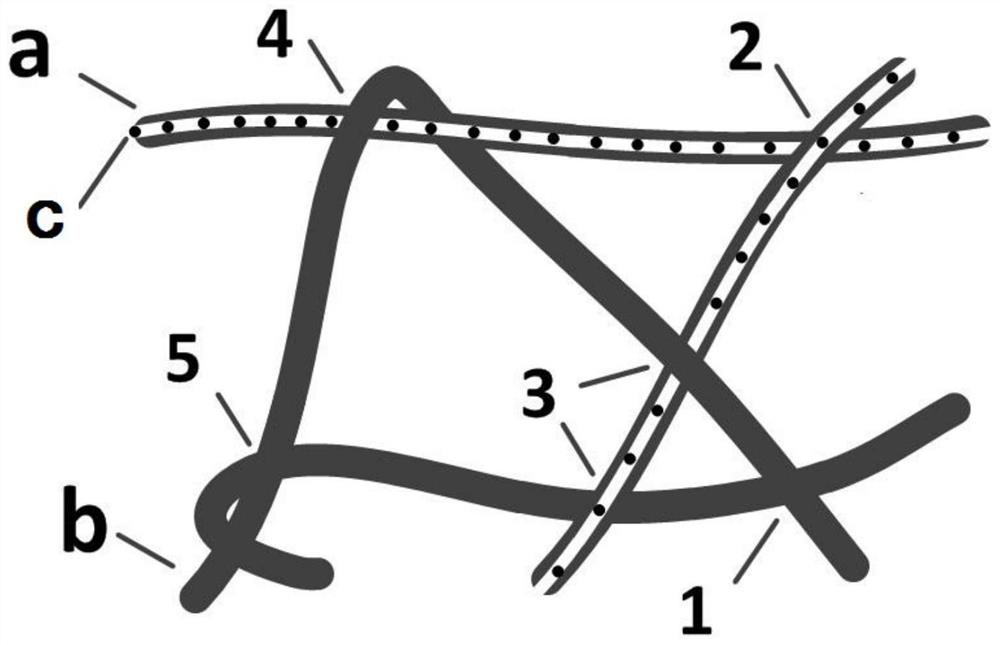

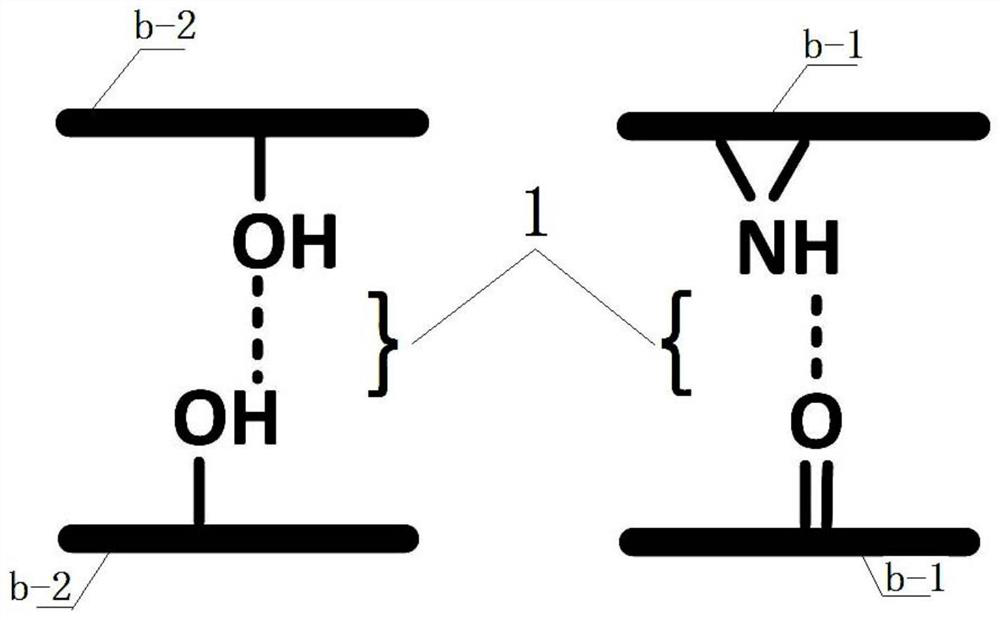

[0047] A 0.01 mol / L europium nitrate solution is configured, and the solvent composition thereof is that the mass ratio of alcohol to water is 1:1 (preferably ethanol). A 0.01 mol / L trimesic acid organic ligand solution is configured, and the solvent composition, alcohol and water mass ratio is 2:1 (preferably ethanol). The prepared metal salt europium nitrate solution and the trimesic acid organic ligand solution were blended at a volume ratio of 1:1, then placed in a water bath shaker at 20°C, and vibrated uniformly for 12 hours to prepare metal-organic framework fibers. The metal-organic framework fibers were placed in silver nitrate solution for adsorption for 30 minutes, taken out for suction filtration, washed, and then put into ethanol for 10 hours of reaction to prepare Eu(BTC)MOFS nanofibers doped with nano-metallic silver particles inside;

[0048] The thermoplastic nanofiber (polyamide) and the Eu(BTC)MOFS nanofiber doped with nano-metallic silver particles are disp...

Embodiment 2

[0058] A 0.1 mol / L europium nitrate solution is configured, and the solvent composition is that the mass ratio of alcohol to water is 1:1 (preferably methanol). A 0.1 mol / L 1,3,5-tris(4-carboxyphenyl)benzene (BTBC) organic ligand solution is prepared, and the solvent composition is an alcohol-water mass ratio of 2:1 (preferably methanol). Blend the prepared metal salt europium nitrate solution and 1,3,5-tris(4-carboxyphenyl)benzene (BTBC) organic ligand solution at a volume ratio of 1:1, and then place it on a water bath shaker at 20°C , prepared Eu(BTBC)MOFS nanofibers by shaking evenly for 12h, placed the Eu(BTBC)MOFS nanofibers in copper sulfate solution for adsorption for 30min, took them out for suction filtration and washing, and then put them into NaHBO 4 Reacting in medium for 5h, the Eu(BTBC)MOFS nanofibers doped with nano metal copper particles inside were prepared;

[0059] Disperse thermoplastic nanofibers (polyamide) and the Eu(BTBC) MOFS nanofibers doped with na...

Embodiment 3

[0062] A 0.15 mol / L europium nitrate solution is prepared, and the solvent composition is that the mass ratio of alcohol to water is 1:1. A 0.15 mol / L nitrilotriacetic acid (NTA) organic ligand solution was prepared, and the solvent composition was that the mass ratio of alcohol to water was 2:1. The prepared metal salt europium nitrate solution and nitrilotriacetic acid (NTA) organic ligand solution were blended at a volume ratio of 1:1, then placed in a water bath shaker at 20°C, and evenly shaken for 12 hours to prepare Eu(NTA) MOFs nanofibers, put the Eu(NTA)MOFs nanofibers in the palladium chloride solution for adsorption for 30min, take out the suction filtration, wash, then put in NaHBO 4 Reacting in medium for 5h, the Eu(NTA)MOFs nanofibers doped with nano metal palladium particles inside were prepared;

[0063] The thermoplastic nanofiber (polyamide) and the Eu(NTA)MOFs nanofiber doped with nano metal palladium particles are dispersed in alcohol water to form a suspe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com