Magnetic rod-shaped nano-hydroxyapatite material and preparation method thereof

A nano-hydroxyapatite, magnetic rod technology, applied in nanotechnology, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of difficult size regulation, poor dispersion, and difficult to control the synthesis of HAP nanoparticles, and achieve size The effect of uniformity, good dispersion and mild reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Mix sodium oleate, ethanol and oleylamine at a ratio of 1:3:1 to obtain 20 mL of mixed solution A, add 10 mL of calcium chloride aqueous solution (concentration is 0.1 mol / L), and stir at 600 rpm for 30 minutes to obtain mixed solution B Add 10mL disodium hydrogen phosphate solution (concentration is 0.06mol / L) again, obtain mixed solution C with 600 revs / min stirring 30 minutes, keep reaction system pH value 10.0 by adding NaOH aqueous solution in stirring process. Transfer the mixed solution C to a sealed reaction kettle and react at 160°C for 8 hours; the reaction product is cooled to room temperature, precipitated by centrifugation, and washed with a mixed solution of cyclohexane and ethanol at a volume ratio of 2:1 to remove organic impurities , and finally vacuum-dried to obtain a magnetic rod-shaped nano-hydroxyapatite material.

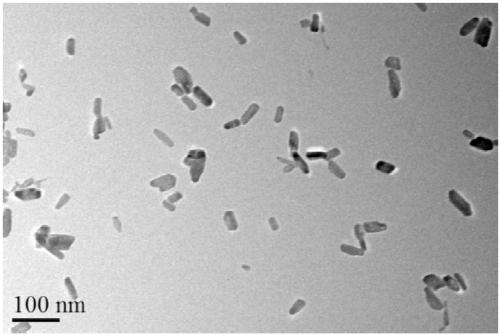

[0035] figure 1 It is the transmission electron micrograph of the magnetic rod-shaped nano-hydroxyapatite made under the process cond...

Embodiment 2

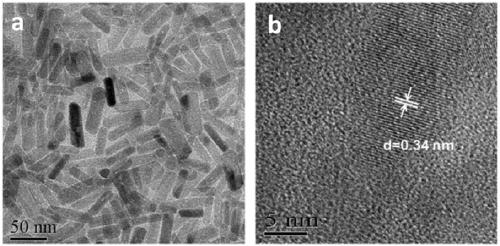

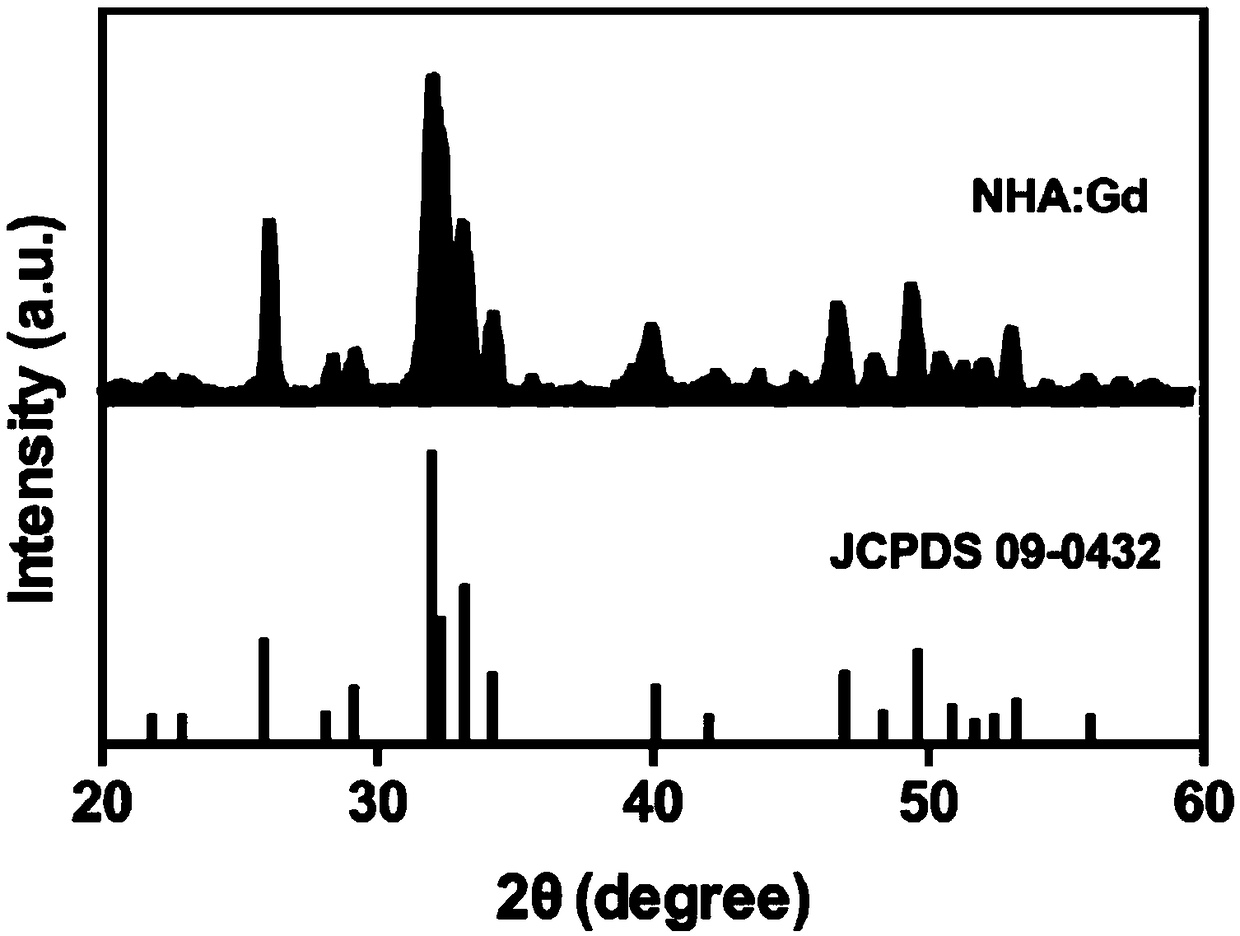

[0037] Mix sodium oleate, ethanol and oleylamine in a ratio of 1:3:1 to obtain 20mL mixed solution A; prepare an aqueous solution of calcium chloride and gadolinium salt, wherein the concentration of calcium chloride is 0.1mol / L, and the concentration of gadolinium chloride Is 0.002mol / L (the molar ratio of gadolinium ion and calcium ion is 0.02), the aqueous solution 10mL of calcium chloride and gadolinium salt is added in the mixed solution A, stirs 30 minutes with 600 rev / min to obtain mixed solution B; 10 mL of disodium hydrogen phosphate solution (concentration is 0.06 mol / L), was stirred at 600 rpm for 30 minutes to obtain mixed solution C, and the pH value of the reaction system was kept at 10.0 by adding NaOH aqueous solution during the stirring process. Transfer the mixed solution C to a sealed reaction kettle and react at 160°C for 8 hours; the reaction product is cooled to room temperature, precipitated by centrifugation, and washed with a mixed solution of cyclohexa...

Embodiment 3

[0042]Mix sodium oleate, ethanol and oleylamine in a ratio of 1:3:1 to obtain 20mL mixed solution A; prepare an aqueous solution of calcium chloride and gadolinium salt, wherein the concentration of calcium chloride is 0.1mol / L, and the concentration of gadolinium chloride Is 0.005mol / L (the molar ratio of gadolinium ion and calcium ion is 0.05), the aqueous solution 10mL of calcium chloride and gadolinium salt is added in the mixed solution A, stirs with 600 revs / min for 30 minutes to obtain mixed solution B; 10 mL of disodium hydrogen phosphate solution (concentration is 0.06 mol / L), was stirred at 600 rpm for 30 minutes to obtain mixed solution C, and the pH value of the reaction system was kept at 10.0 by adding NaOH aqueous solution during the stirring process. Transfer the mixed solution C to a sealed reaction kettle and react at 160°C for 8 hours; the reaction product is cooled to room temperature, precipitated by centrifugation, and washed with a mixed solution of cyclo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com