Furan resin modified silicate composite daub and preparation method thereof

A technology of furan resin and silicate, which is applied in the field of chemical anti-corrosion mastic, which can solve the problems of large consumption of mastic, corrosion and wear of the surface of mastic, and influence on bonding performance, so as to reduce physical wear consumption, improve overall mechanical properties, and resist thermal shock The effect of both performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

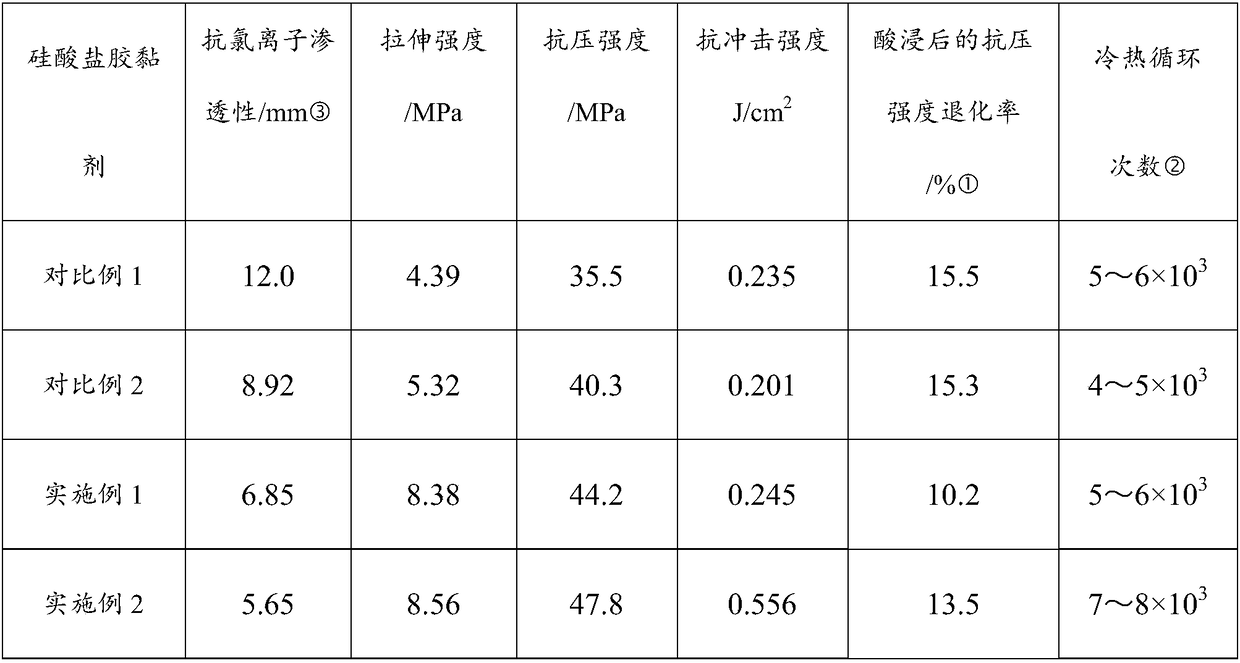

Examples

preparation example Construction

[0058] In other examples of the present invention, the preparation method of the above-mentioned silicate composite cement comprises the following steps:

[0059] 1) The liquid furfural phenol resin, reactive diluent cyclohexanone, ethyl sulfate and potassium water glass are mixed and reacted in a stirring state by weight percentage to prepare component A;

[0060] 2) Mixing the inorganic rigid particles by weight percentage to obtain component B;

[0061] 3) The component B is mixed with the component A and stirred for 10-20 minutes to obtain a silicate composite cement.

[0062] In a preferred embodiment, in step 1), the liquid furfural phenol resin is added to the reaction kettle and stirred, and the temperature is increased to 55-60°C, and then the reactive diluent cyclohexanone is added, mixed and stirred evenly, and the heat preservation reaction 1- 2 hours, such as 1.5 hours; keep the temperature constant, continue to stir and add ethyl sulfate, react for 10-15 minutes...

Embodiment 1

[0081] 1) Add 15wt% liquid furfural phenol resin in the chemical reaction kettle, start the stirring equipment, increase the temperature to 55°C, add 5wt% cyclohexanone (reactive diluent), mix and stir evenly, keep warm for 1.5 hours Keep the temperature constant and continue to stir, and add 6wt% ethyl sulfate in the chemical reaction kettle, react for 10min; add 74wt% potassium water glass and continue to stir for 15min after cooling down to room temperature, and prepare component A;

[0082] 2) Mix dry 20wt% sodium aluminosilicate, 7wt% silicon micropowder, 20wt% graphite and 30wt% asbestos powder, grind to 600 mesh and add 2wt% aluminum powder, 11wt% fluosilicic acid Sodium and 10wt% glass fiber are made into mixed filler as component B for later use;

[0083] 3) When heated to 50°C, add 50 wt% of component B to 50 wt% of component A in proportion, and stir in a mixer for 20 minutes to obtain a modified silicate composite cement;

[0084] 4) After applying the obtained si...

Embodiment 2

[0087] 1) Add 18wt% liquid furfural phenol resin in the chemical reaction kettle, start the stirring equipment, increase the temperature to 55°C, add 6wt% cyclohexanone (reactive diluent), mix and stir evenly, and keep warm for 1.5 hours Keep the temperature constant and continue to stir, and add 7wt% ethyl sulfate in the chemical reaction kettle, react for 15min; add 69wt% potassium water glass and continue to stir for 15min after cooling down to room temperature, and prepare component A;

[0088] 2) Mix dry 22wt% sodium aluminosilicate, 5wt% silicon micropowder, 18wt% graphite and 30wt% asbestos powder, grind to 600 mesh and add 3wt% aluminum powder, 12wt% fluosilicic acid Sodium and 10wt% glass fiber are made into mixed filler as component B for later use;

[0089] 3) under heating to 45°C, add 45wt% of component B to 55wt% of component A in proportion, and stir in a mixer for 20 minutes to obtain a modified silicate composite cement;

[0090] 4) After applying the obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com