Wash-resistant waterborne negative ion diatom ooze formula and preparation method thereof

A technology that is resistant to scrubbing and negative ions. It is applied to ceramic products, other household utensils, and other applications. It can solve the problems of easy powder loss, low adsorption efficiency, and poor air permeability of diatom mud, so as to keep the room clean, and the processing technology is simple. The effect of dedusting phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment (1

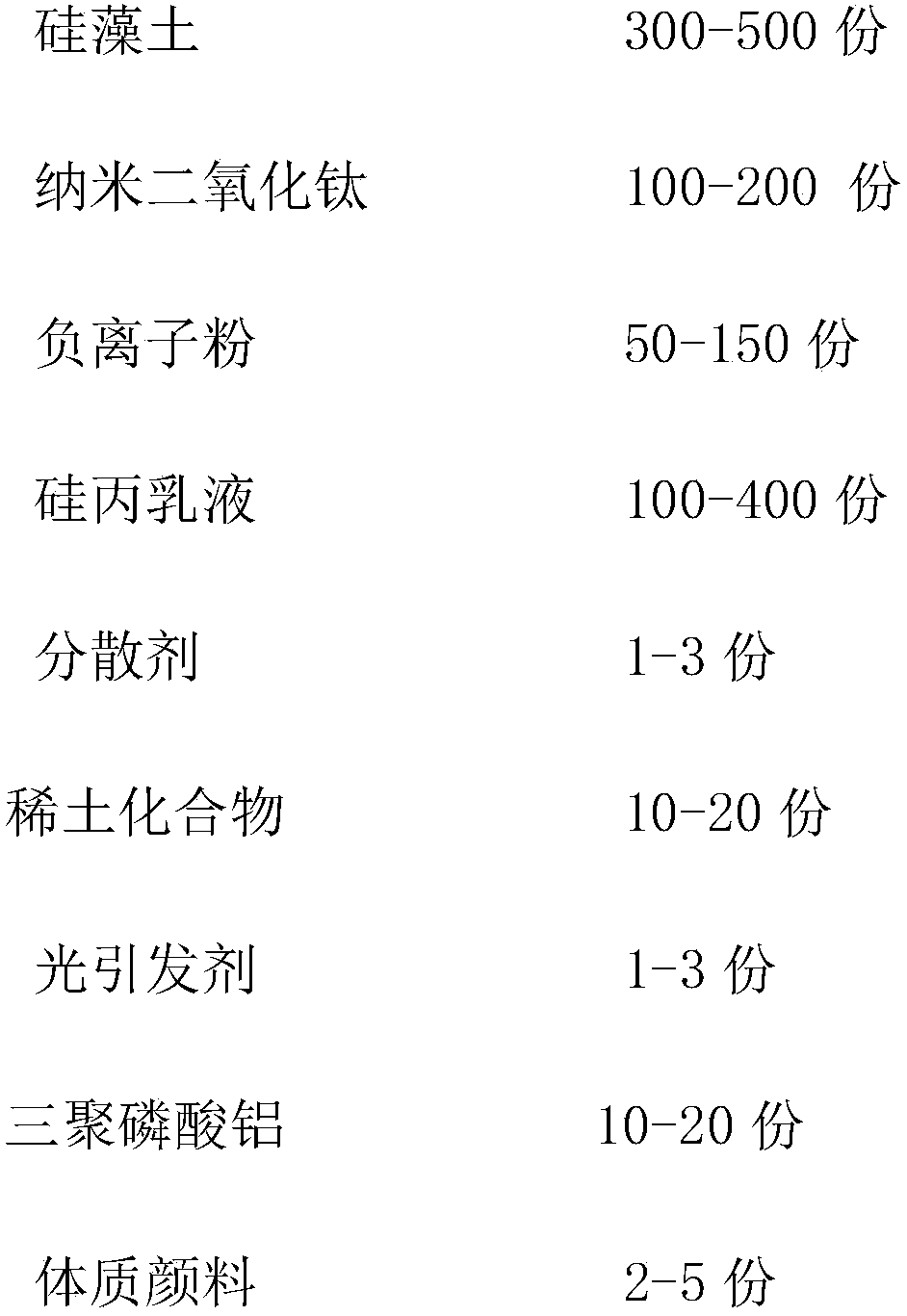

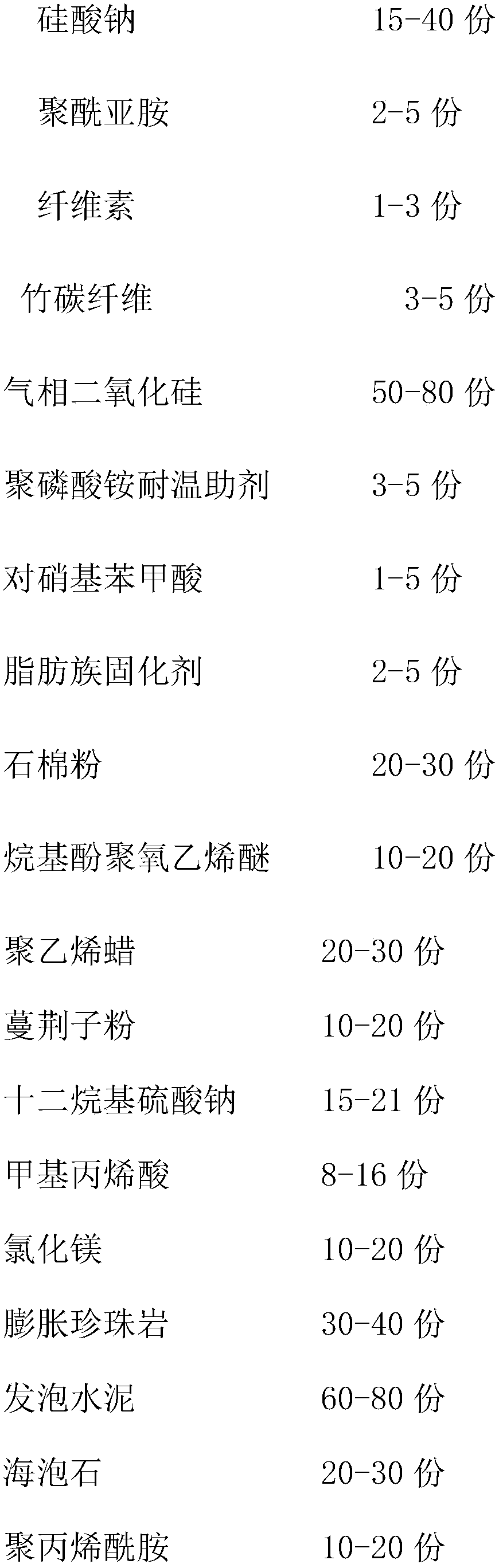

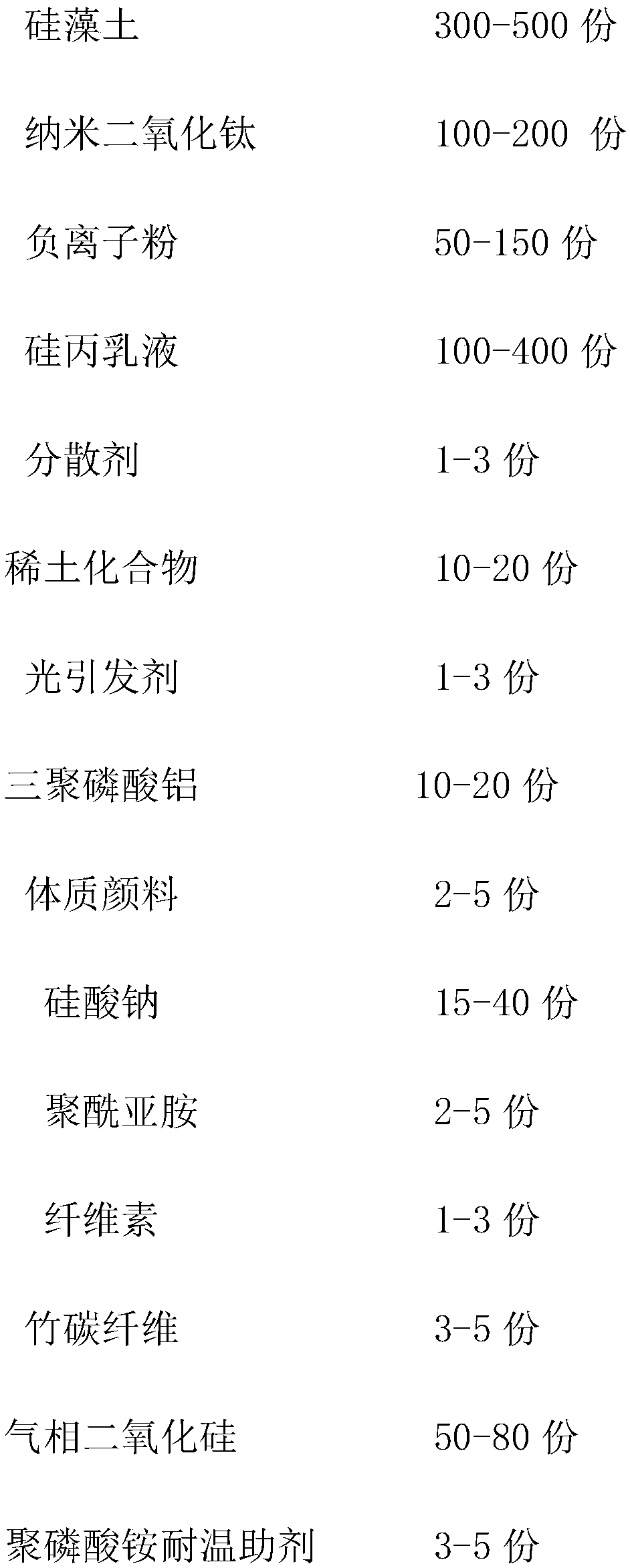

[0036] A scrub-resistant water-based negative ion diatom mud formula, characterized in that: it includes component A and component B, wherein component A is composed as follows in parts by weight: 300 parts of diatomite, 100 parts of nano-titanium dioxide, negative ion 50 parts of powder, 100 parts of silicone acrylic emulsion, 1 part of dispersant, 10 parts of rare earth compound, 1 part of photoinitiator, 10 parts of aluminum tripolyphosphate, 2 parts of extender pigment, 15 parts of sodium silicate, 2 parts of polyimide, 1 part of cellulose, 3 parts of bamboo carbon fiber, 50 parts of fumed silica, 3 parts of ammonium polyphosphate temperature resistance additive, 1 part of p-nitrobenzoic acid, 2 parts of aliphatic curing agent, 20 parts of asbestos powder, alkylphenol 10 parts of polyoxyethylene ether, 20 parts of polyethylene wax, 10 parts of vitex powder, 15 parts of sodium lauryl sulfate, 8 parts of methacrylic acid, 10 parts of magnesium chloride, 30 parts of expanded p...

Embodiment (2

[0039] A scrub-resistant water-based negative ion diatom mud formula, characterized in that: it includes component A and component B, wherein component A is composed as follows in parts by weight: 400 parts of diatomite, 150 parts of nano-titanium dioxide, negative ion 100 parts of powder, 250 parts of silicone acrylic emulsion, 2 parts of dispersant, 15 parts of rare earth compound, 2 parts of photoinitiator, 15 parts of aluminum tripolyphosphate, 3.5 parts of extender pigment, 27.5 parts of sodium silicate, 3.5 parts of polyimide , 2 parts of cellulose, 4 parts of bamboo carbon fiber, 65 parts of fumed silica, 4 parts of ammonium polyphosphate temperature-resistant additive, 3 parts of p-nitrobenzoic acid, 3.5 parts of aliphatic curing agent, 25 parts of asbestos powder, alkyl 15 parts of phenol polyoxyethylene ether, 25 parts of polyethylene wax, 15 parts of vitex powder, 18 parts of sodium lauryl sulfate, 12 parts of methacrylic acid, 15 parts of magnesium chloride, 35 part...

Embodiment (3

[0042] A scrub-resistant water-based negative ion diatom mud formula, characterized in that: it includes component A and component B, wherein component A is composed as follows in parts by weight: 500 parts of diatomite, 200 parts of nano-titanium dioxide, negative ion 150 parts of powder, 400 parts of silicone acrylic emulsion, 3 parts of dispersant, 20 parts of rare earth compound, 3 parts of photoinitiator, 20 parts of aluminum tripolyphosphate, 5 parts of extender pigment, 40 parts of sodium silicate, 5 parts of polyimide , 3 parts of cellulose, 5 parts of bamboo carbon fiber, 80 parts of fumed silica, 5 parts of ammonium polyphosphate temperature resistance additive, 5 parts of p-nitrobenzoic acid, 5 parts of aliphatic curing agent, 30 parts of asbestos powder, alkyl 20 parts of phenol polyoxyethylene ether, 30 parts of polyethylene wax, 20 parts of vitex powder, 21 parts of sodium lauryl sulfate, 16 parts of methacrylic acid, 20 parts of magnesium chloride, 40 parts of ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com