Yeast zinc leaf fertilizer, making method and application

A production method and technology of foliar fertilizer, which is applied in the field of yeast zinc foliar fertilizer, can solve the problems of low nutrient penetration rate absorbed by the leaf surface, waste of liquid medicine, and low leaf surface, so as to reduce root infection and disease, reduce waste, The effect of fertilizer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

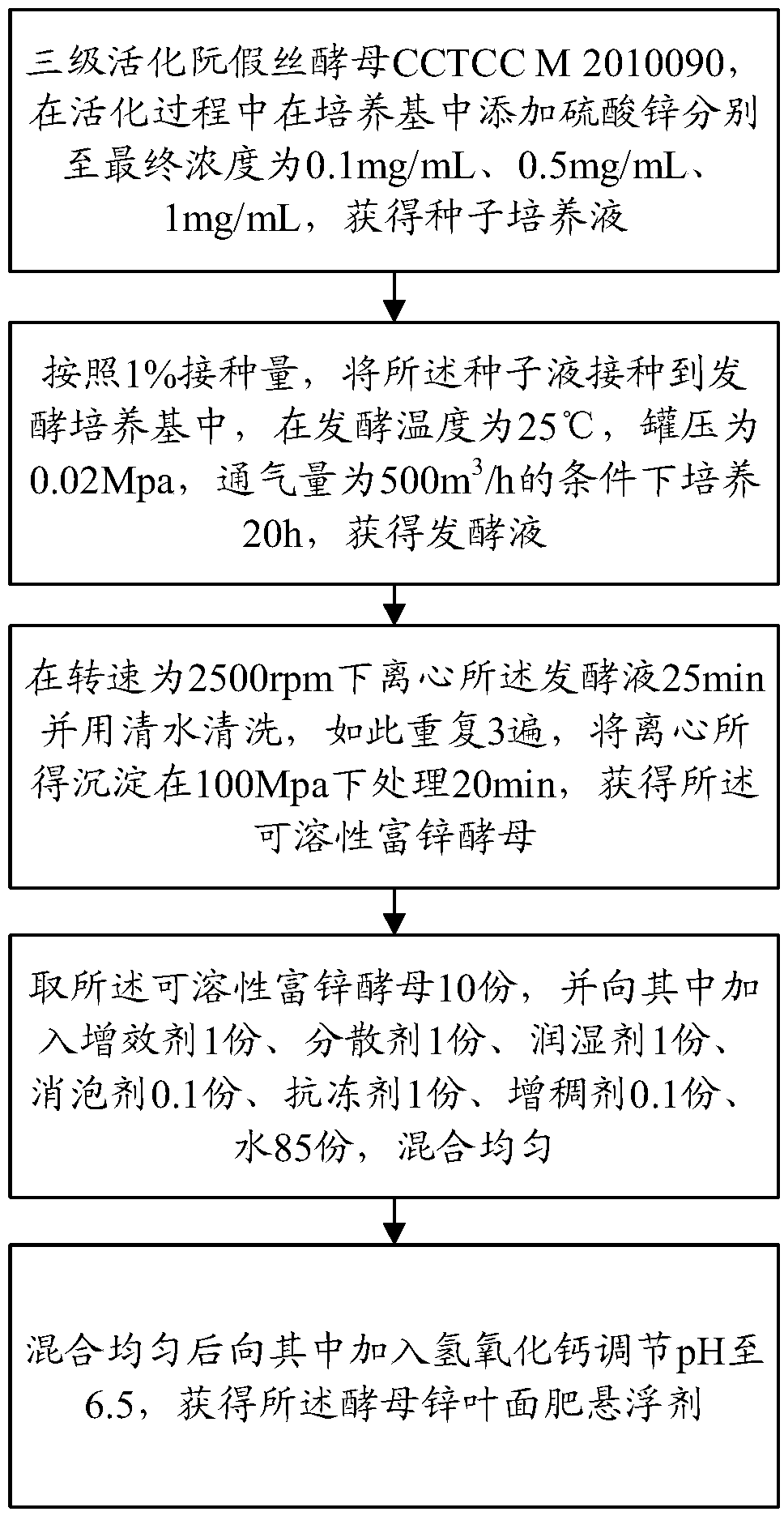

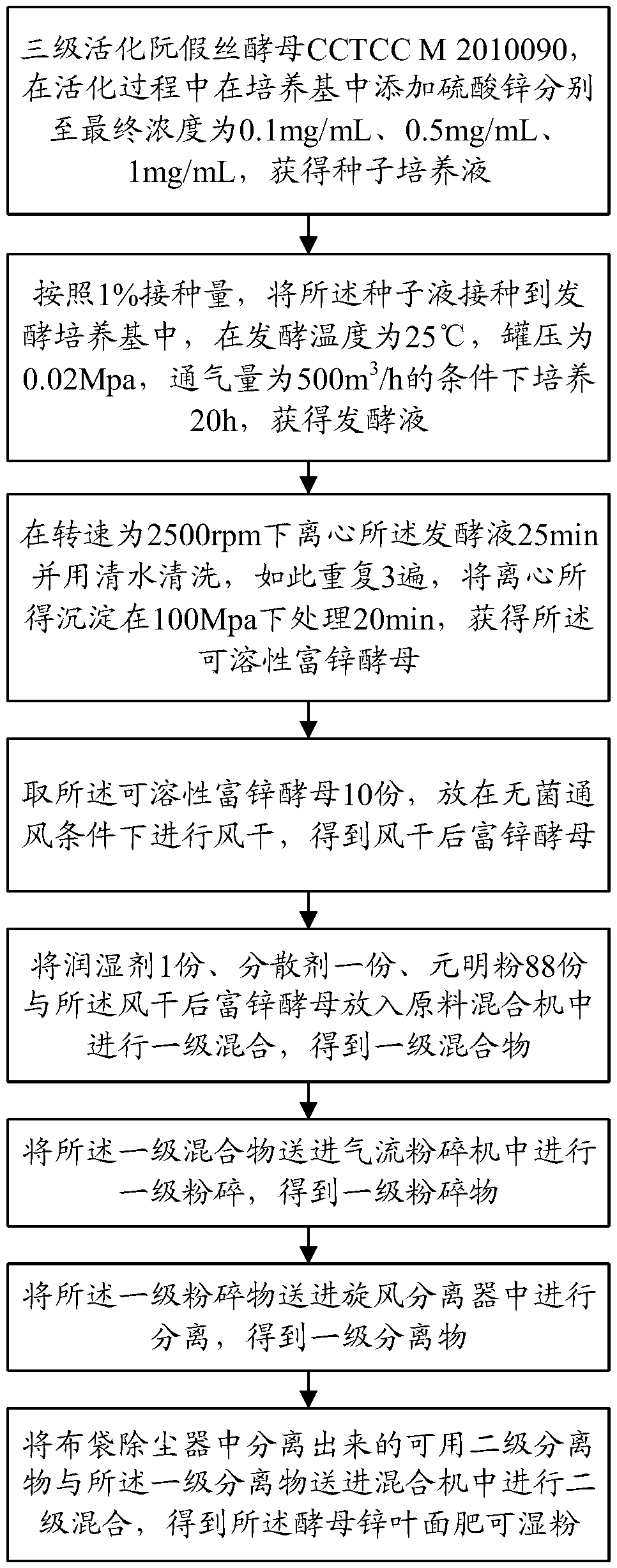

Method used

Image

Examples

Embodiment 1

[0040]Specific examples of the yeast zinc foliar fertilizer, production method and application described in the application, the raw materials in the method include the following parts by weight, wherein 10 parts of soluble zinc-rich yeast, 1 part of synergist, 1 part of dispersant, wetting 1 part of agent, 0.1 part of defoamer, 1 part of antifreeze, 0.1 part of thickener, 85 parts of water. Wherein the antifreezing agent in the present embodiment is ethylene glycol, and the antifreezing agent in another embodiment of the present invention is one or more in ethylene glycol, methanol, ethanol, water-soluble amide, calcium chloride or salt water kind of mixture. The defoamer in this embodiment is polyoxyethylene polyoxypropanol amine ether, and the defoamer in another embodiment of the present invention is emulsified silicone oil, higher alcohol fatty acid ester complex, polyoxyethylene polyoxypropylene One or more mixtures of pentaerythritol ether, polyoxyethylene polyoxypropa...

Embodiment 2

[0059] Another specific embodiment of yeast zinc foliar fertilizer, production method and application described in the present application, the raw materials in this embodiment include the following parts by weight, wherein 35 parts of soluble zinc-rich yeast, 10 parts of synergist, and 15 parts of dispersant , 15 parts of wetting agent, 0.5 parts of defoamer, 5 parts of antifreeze, 1.5 parts of thickener, 20 parts of water. Wherein the antifreeze in the present embodiment is ethanol, the antifreeze in another embodiment of the present invention is one or more mixtures in ethylene glycol, methanol, ethanol, water-soluble amide, calcium chloride or salt water . The defoamer in this embodiment is polyoxypropylene glyceryl ether, and the defoamer in another embodiment of the present invention is emulsified silicone oil, higher carbon alcohol fatty acid ester compound, polyoxyethylene polyoxypropylene pentaerythritol ether, polyoxypropylene One or more mixtures of oxyethylene pol...

Embodiment 3

[0069]A practical example of yeast zinc foliar fertilizer, production method and application described in the application, the raw materials in this example include the following parts by weight, wherein 60 parts of soluble zinc-rich yeast, 20 parts of synergist, and 30 parts of dispersant , 30 parts of wetting agent, 1 part of defoamer, 10 parts of antifreeze, 3 parts of thickener, 50 parts of water. Wherein the antifreezing agent in the present embodiment is calcium chloride, and the antifreezing agent in another embodiment of the present invention is one or more in ethylene glycol, methanol, ethanol, water-soluble amide, calcium chloride or salt water kind of mixture. The defoamer in this embodiment is emulsified silicone oil, and the defoamer in another embodiment of the present invention is emulsified silicone oil, higher carbon alcohol fatty acid ester complex, polyoxyethylene polyoxypropylene pentaerythritol ether, polyoxyethylene poly One or more mixtures of oxypropan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com