Preparation method of porous graphene/silver nanoparticle composite lithium metal secondary battery negative current collector

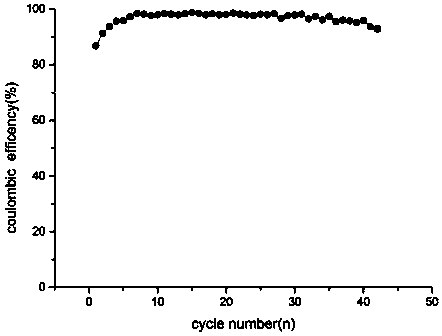

A technology of silver nanoparticles and porous graphene, which is applied in the field of preparation of lithium metal battery materials, can solve the problems of short battery cycle life, obstacles to the application of metal lithium negative electrodes, and poor safety performance, so as to reduce local current density and improve service life , The effect of reducing the overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

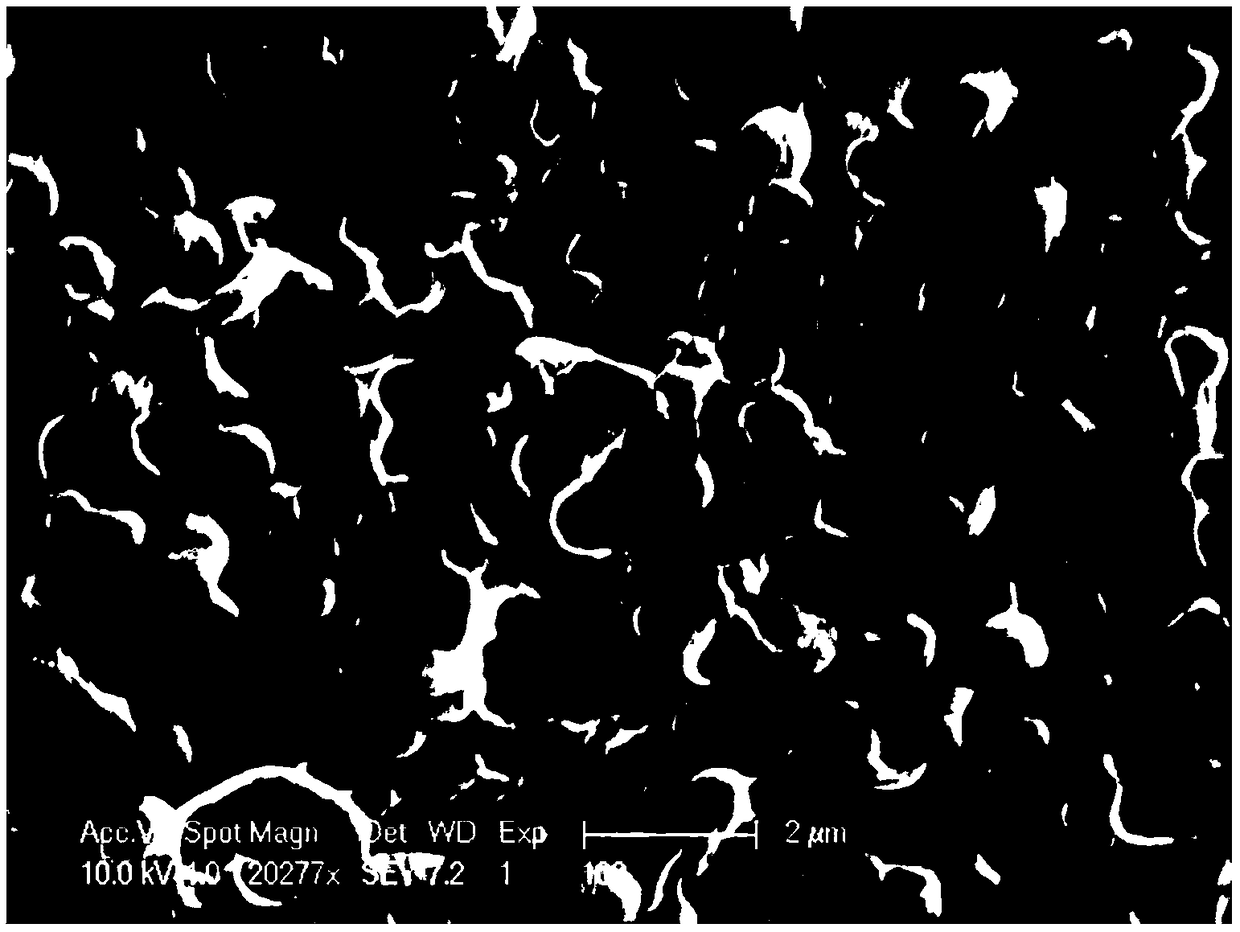

[0027] a) Ultrasonicate graphene oxide in aqueous solution for 1h to form a uniform graphene oxide solution with a concentration of 0.5mg / ml

[0028] b) adding 0.1% silver nanoparticles of graphene oxide to the polystyrene microsphere (particle size: 720nm) solution with a mass fraction of 0.5%, magnetically stirring for 20min under ultraviolet light irradiation

[0029] c) Fully mix the solutions in steps a and b and stir on a magnetic stirrer for 20min

[0030] d) The solution in step c is vacuum filtered to obtain a graphene oxide / polystyrene microsphere / silver nanoparticle composite material

Embodiment 2

[0032] a) Ultrasonicate graphene oxide in aqueous solution for 1 h to form a uniform graphene oxide solution with a concentration of 1 mg / ml

[0033] b) adding silver nanoparticles with 0.2% graphene oxide amount to the silica microsphere (particle diameter: 280nm) solution with a mass fraction of 0.5%, and magnetic stirring for 30min under ultraviolet light irradiation

[0034] c) Fully mix the solutions in steps a and b and stir on a magnetic stirrer for 30min

[0035] d) vacuum filter the solution in step c to obtain a graphene oxide / silicon dioxide microsphere / silver nanoparticle composite material

[0036] e) Soak the material in step d in hydrogen fluoride solution for 30 minutes to remove the silica template, and then treat it at 800°C for 6h (5°C / min) to obtain the desired material

Embodiment 3

[0038] a) Ultrasonicate graphene oxide in aqueous solution for 1 h to form a uniform graphene oxide solution with a concentration of 2 mg / ml

[0039] b) adding silver nanoparticles with 0.3% graphene oxide amount to the solution of polystyrene microspheres (particle size: 320nm) with a mass fraction of 1%, and magnetic stirring for 40min under ultraviolet light irradiation

[0040] c) Fully mix the solutions in steps a and b and stir on a magnetic stirrer for 40min

[0041] d) The solution in step c is vacuum filtered to obtain a graphene oxide / polystyrene microsphere / silver nanoparticle composite material

[0042] e) Treat the material in step d at 400°C for 3h (2°C / min) to remove the polystyrene template, and then treat it at 900°C for 4h (5°C / min) to obtain the desired material

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com