Micro-nano composite particle and mechanical load embedding preparation process thereof

A technology of composite particles and micro-nano composites, applied in the fields of aluminum compounds, inorganic chemistry, nanotechnology, etc., can solve the problems of small amount of fillers and inability to play their role

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

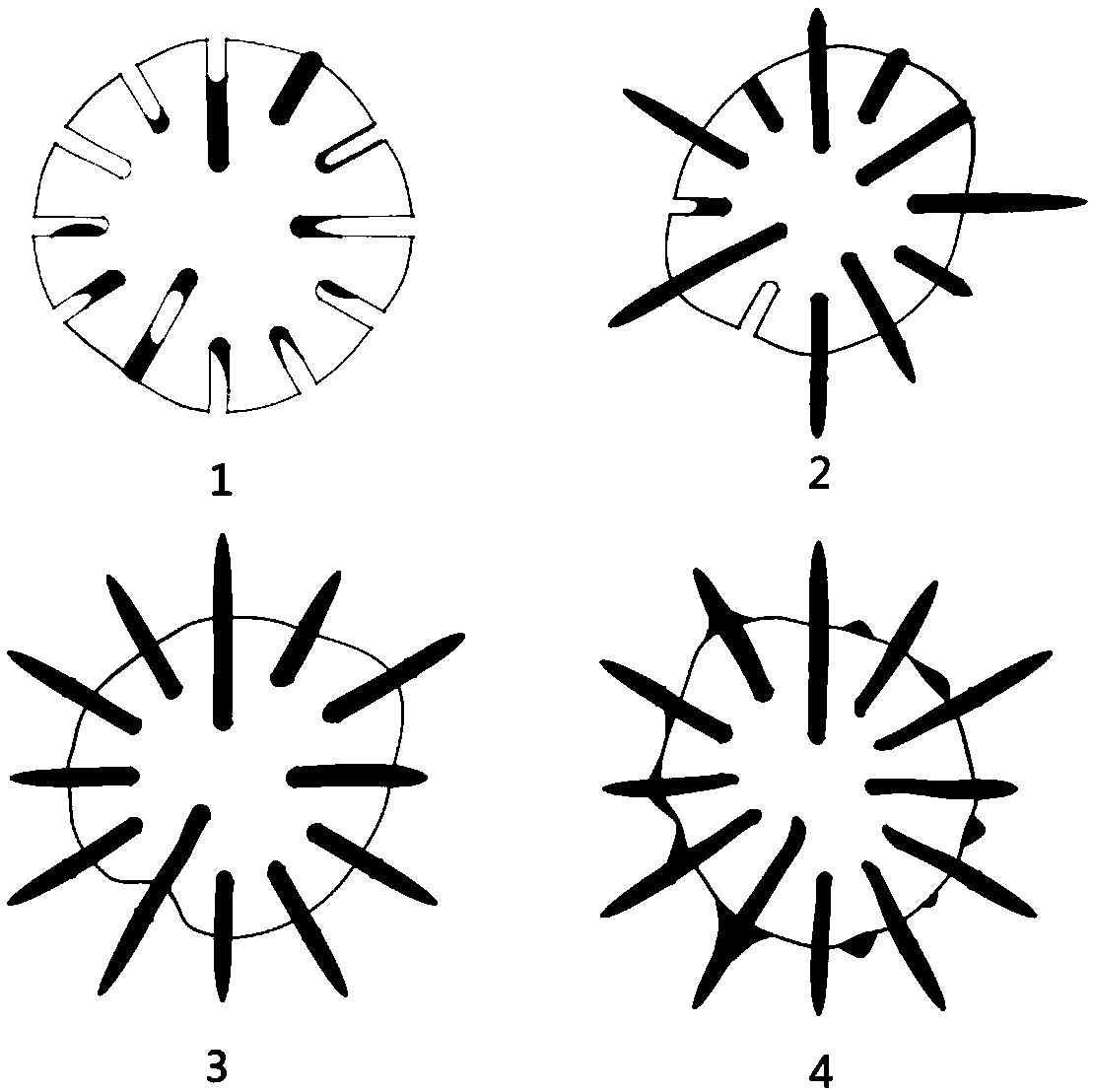

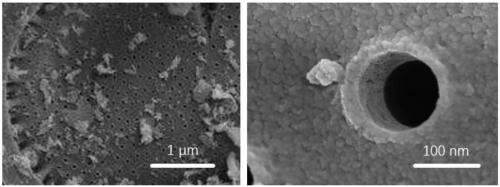

[0071] In the composite particle provided by this embodiment, nanometer and nanoscale particles smaller than the pore diameter of the porous micronanoparticle are inserted into the porous micronanoparticle to form three-dimensional porous and / or thorn-like micronanocomposite particles, three-dimensionally porous and / or the single pore embedding amount of spiny micro-nano composite particles is 5-100% of the pore volume, and the BET nitrogen adsorption specific surface area is 30m 2 / g~350m 2 / g, see figure 1 As shown, the state composition of composite particles means that the nanoscale and below-nanoscale particles may not be inserted, partially inserted, or fully inserted and become thorny, and even a certain degree of nanometer and below-nanoscale particles are attached to the surface of the matrix. figure 2 It is 10000x and 100000x scanning electron micrographs of three-dimensional porous / thorny micro-nano composite particles.

[0072]Specifically, the matrix of the ab...

Embodiment 2

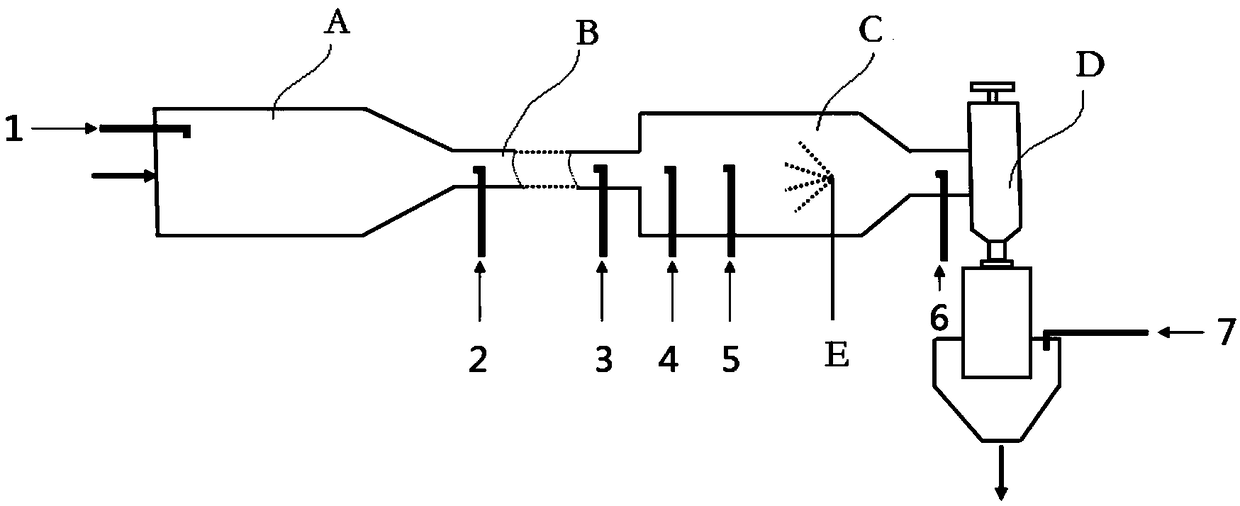

[0075] This embodiment provides a preparation process for the above-mentioned composite particles, comprising the following steps:

[0076] S1. Dissolve zinc nitrate hexahydrate in deionized water to form a 10g / ml zinc nitrate solution, stir for 2 minutes and set aside;

[0077] S2. Mix silicon dioxide and aluminum oxide porous micro-nano composite substrate with methanol to obtain a solution of porous micro-nano particles, place it in an ultrasonic instrument for ultrasonic dispersion, the ultrasonic frequency is 60Hz, the temperature is below 50°C, and the ultrasonic time is For 0.1h, the concentration obtained is 20g / ml porous micro-nano particle suspension; in the present embodiment, the composite substrate is made of 20% silicon dioxide and 80% aluminum oxide in parts by weight;

[0078] S3. Take ammonia water and dissolve it in deionized water, and prepare ammonia water with a concentration of 30% for subsequent use;

[0079] S4. Mix the porous micro-nano particle suspe...

Embodiment 3

[0085] This embodiment provides a preparation process for the above-mentioned composite particles, comprising the following steps:

[0086] S1. Dissolve copper sulfate in deionized water to form a 20g / ml copper sulfate solution, stir for 2 minutes and set aside;

[0087] S2. Mix calcium carbonate and aluminum oxide porous micro-nano composite substrate with ethanol to obtain a solution of porous micro-nano particles, place it in an ultrasonic instrument for ultrasonic dispersion, the ultrasonic frequency is 30 Hz, the temperature is below 80 ° C, and the ultrasonic time is 2h, the obtained concentration is 1g / ml porous micro-nano particle suspension; in the present embodiment, the composite substrate is made of 95% calcium carbonate and 5% aluminum oxide in parts by weight;

[0088] S3. Take urea and dissolve it in deionized water, and configure it as a buffer solution with a concentration of 50% for later use (ammonium and copper ions will produce complexes that cannot be pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Hole depth | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com