Method for preparing tissue repair adhesion conductive hydrogel

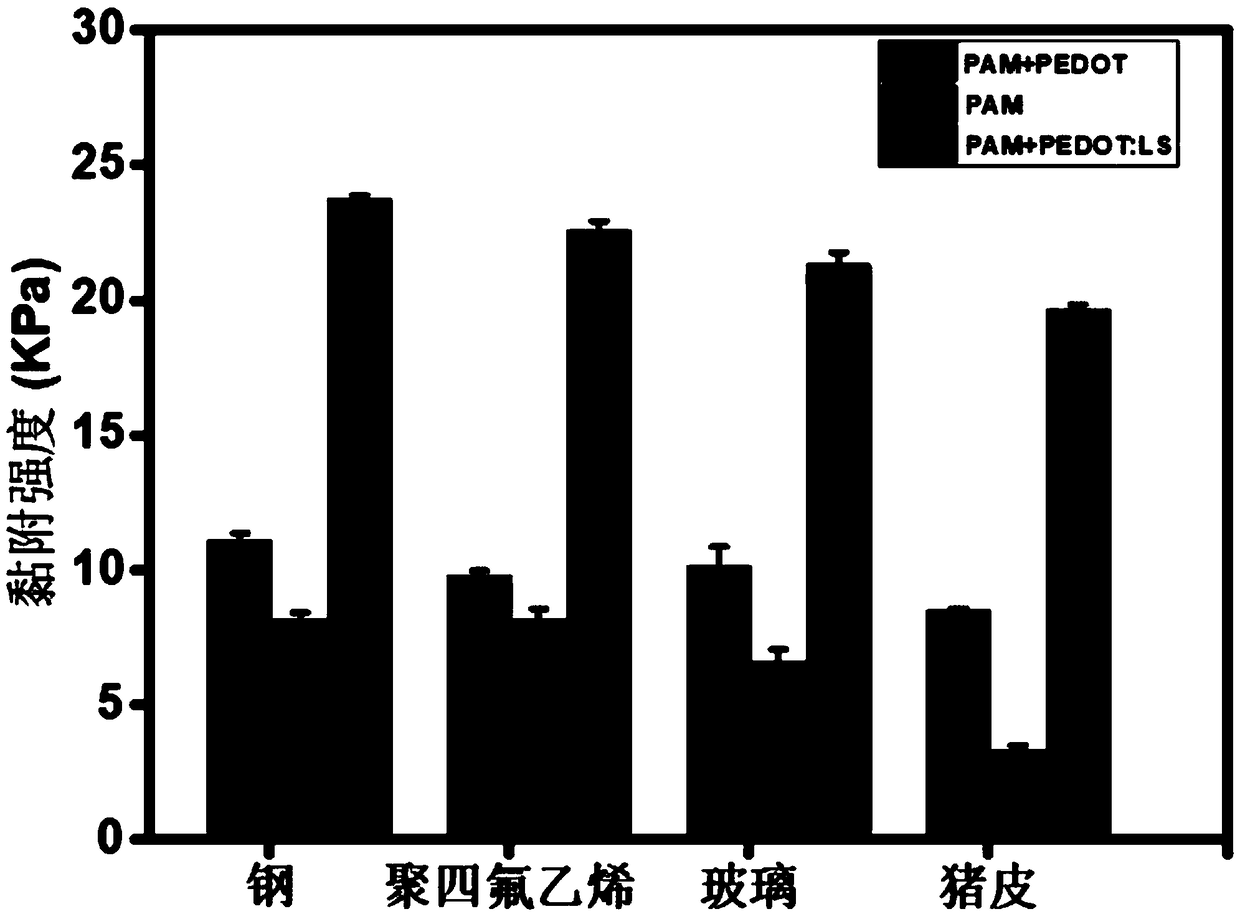

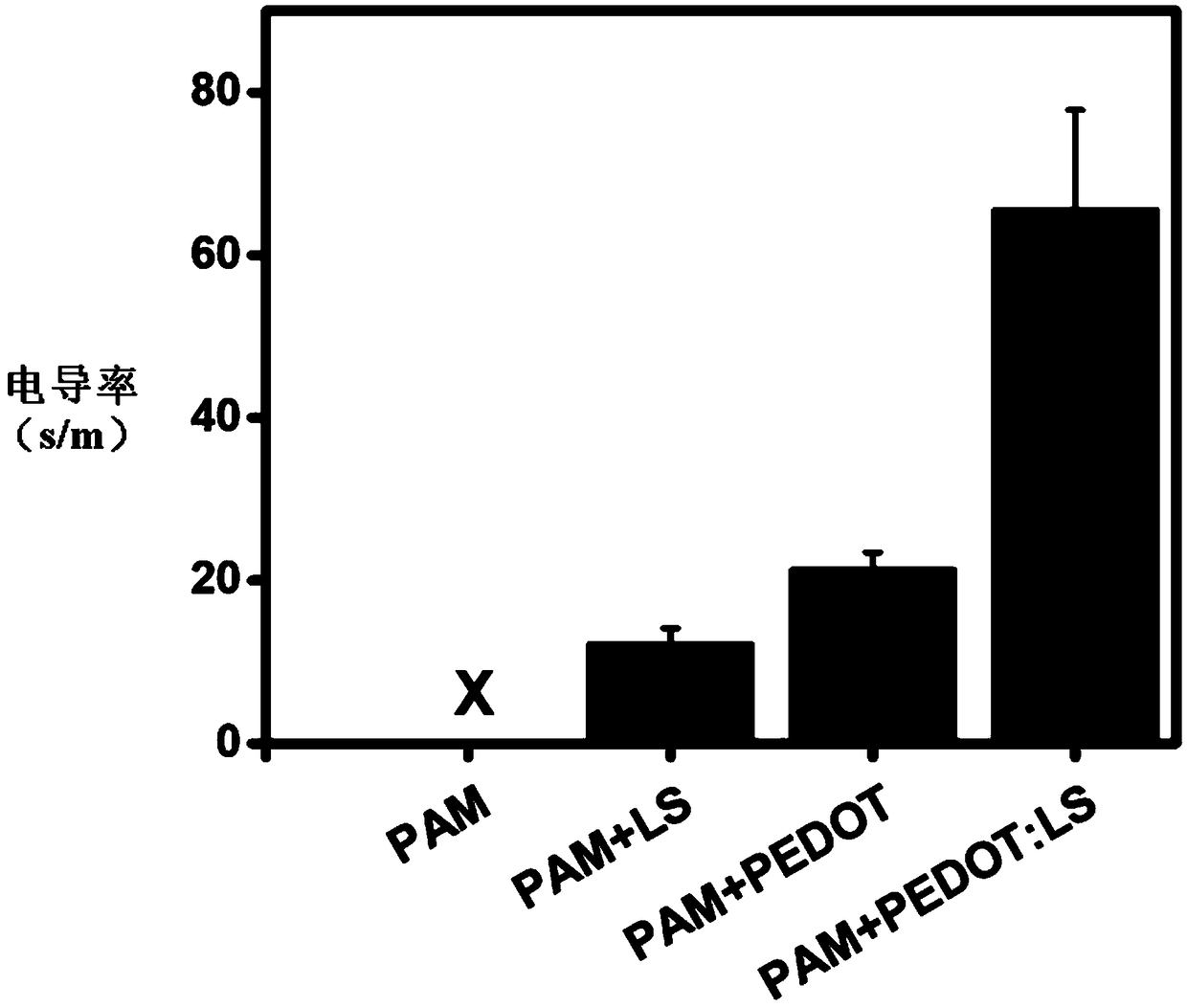

A conductive hydrogel and tissue repair technology, applied in the direction of electrotherapy, conductive adhesives, electrodes, etc., can solve the problems of unchanged application, poor adhesion performance, and decreased electrical conductivity, and achieve good biocompatibility, good Effects of adhesion ability and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing an adhesive conductive hydrogel for tissue repair, comprising the following steps:

[0026] Step 1: Dissolve a certain amount of lignin in an alkaline solution, heat the oil bath to 85-95°C, add a certain amount of persulfate or sulfite solution, and react at 85-95°C for 2-3 hours. Obtain sulfonated lignin after natural cooling;

[0027] The alkaline solution is sodium hydroxide or potassium hydroxide, the persulfate is one of potassium persulfate, sodium persulfate and ammonium persulfate, and the sulfite is one of sodium sulfite, ammonium sulfite and potassium sulfite.

[0028] Step 2: add a certain amount of sulfonated lignin and conductive polymer obtained in step 1 into deionized water, acid solution or aqueous solution, add a certain amount of oxidant, and stir at high speed for 24 to 48 hours to obtain composite nanoparticle dispersion solution; the obtained composite nanoparticles were washed with deionized water, centrifuged, and repeate...

Embodiment 1

[0033] A method for preparing an adhesive conductive hydrogel for tissue repair, comprising the following steps:

[0034] A. Sulfonation modification of natural lignin

[0035] Add sodium hydroxide and lignin with a mass ratio of 2:5 to deionized water in sequence to obtain a lignin solution with a mass concentration of 10%; heat the oil bath to 90°C; then add ammonium persulfate 1.5 times the mass of lignin , Ammonium persulfate is configured into a solution with a concentration of 30%; react for 2 hours, and after natural cooling, the sulfonated lignin is formed.

[0036] B. Poly(3,4-ethylenedioxythiophene / sulfonated lignin nanoparticles)

[0037] Dissolving 3,4-ethylenedioxythiophene and the sulfonated lignin obtained in step A in deionized water at a mass ratio of 2:1 to obtain a mixed solution;

[0038] Ammonium persulfate of 1.5 times the mass of 3,4-ethylenedioxythiophene was added to the mixed solution, and the reaction was stirred at high speed for 48 hours to obtai...

Embodiment 2

[0048] A method for preparing an adhesive conductive hydrogel for tissue repair, comprising the following steps:

[0049] A. Sulfonation modification of natural lignin

[0050] Add sodium hydroxide and lignin with a mass ratio of 2:5 to deionized water in sequence to obtain a lignin solution with a mass concentration of 10%; heat the oil bath to 90°C; then add ammonium persulfate 1.5 times the mass of lignin , Ammonium persulfate is configured into a solution with a concentration of 30%; react for 2 hours, and after natural cooling, the sulfonated lignin is formed.

[0051] B. Poly(3,4-ethylenedioxythiophene / sulfonated lignin nanoparticles)

[0052] Adding 3,4-ethylenedioxythiophene and the sulfonated lignin obtained in step A to deionized water in a mass ratio of 2:1 to obtain a mixed solution;

[0053] Add iron sulfate twice the mass of 3,4-ethylenedioxythiophene to the mixed solution, and react with high-speed stirring for 48 hours to obtain blue-black poly-3,4-ethylenedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com