Related gene for high-yield L-leucine, construction method for engineering bacteria and application

A leucine and mutant gene technology, applied in the field of microorganisms, can solve the problems of failing to meet the industrial production requirements of leucine, long fermentation acid production cycle, low acid production level, etc., to achieve convenient trait improvement, good growth traits, Produces high-intensity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Construct L-leucine high-efficiency production strain AL03, the specific method is as follows:

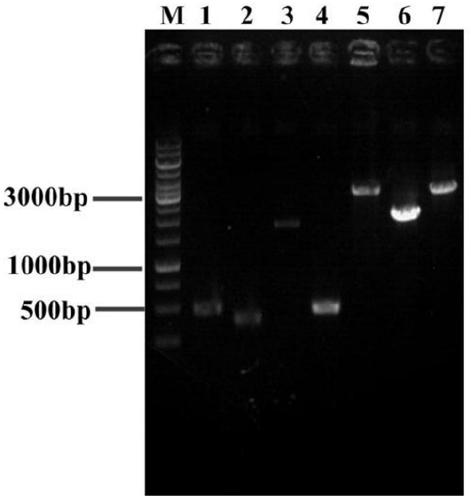

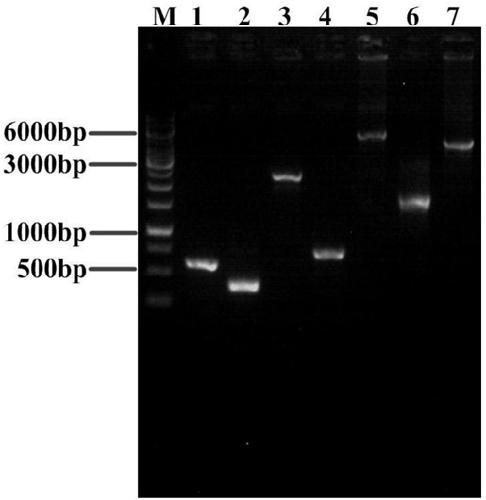

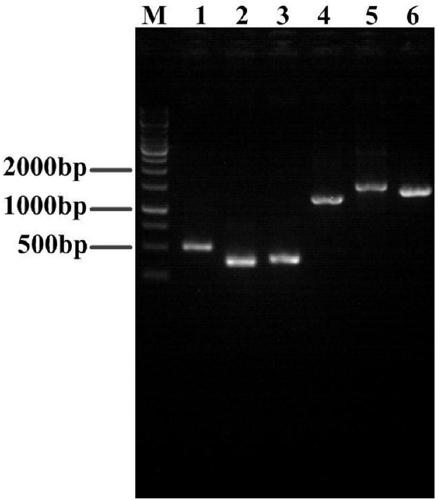

[0029] 1 Integration of isopropylmalate synthase-encoding mutant gene leuA*:

[0030] (1) The leuA mutant gene was integrated into the cgl1135 pseudogene site. Site-directed mutagenesis of the isopropylmalate synthase gene leuA was performed, and the mutant gene leuA* was obtained by PCR; using the genome of Corynebacterium glutamicum ATCC 13032 as a template, the upstream and downstream homology arm fragments of cgl1135 and glutamine were amplified acid Corynebacterium strong promoter Ptuf. PCR reaction conditions (PrimeSTAR HS enzyme): pre-denaturation (95°C) for 5 minutes; then 30 cycles: denaturation (98°C) for 10s, annealing ((Tm-3 / 5)°C) for 15s, extension at 72°C (this Enzyme activity extends about 1kb for 1min; 72°C for 10min; maintain (4°C). The PCR amplification system is shown in Table 2; the primer sequences are shown in Table 1, and have the sequence shown in ...

Embodiment 2

[0054] A method for fermenting and producing L-leucine by using genetic engineering bacteria AL03 strain is as follows:

[0055] (1) Shake flask fermentation

[0056] Slant culture: Streak inoculation of -80°C preserved strains on the activated slant, culture at 32°C for 24 hours, and passage once;

[0057] Shake flask seed culture: Scrape a ring of slanted seeds with an inoculation loop and inoculate in a 500mL Erlenmeyer flask containing 30mL seed medium, seal with twelve layers of gauze, and incubate at 32°C and 200rpm for 7-10h;

[0058] Shake flask fermentation culture: Inoculate 10-15% inoculum into a 500 mL Erlenmeyer flask containing fermentation medium (final volume is 30 mL), seal with twelve layers of gauze, 32°C, 200r / min shaking culture, during fermentation Maintain the pH at 7.0-7.2 by adding ammonia water; add 60% (m / v) glucose solution to maintain the fermentation; the fermentation period is 24-30h;

[0059] The composition of the slant medium is: glucose 5g / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com