Preparation method of GaN-based low-order surface grating DFB laser

A technology of DFB lasers and surface gratings, applied in lasers, semiconductor lasers, phonon exciters, etc., can solve the problems of high cost, small grating area, large-area device preparation, etc., and achieve high side mode suppression ratio and single mode selection Good performance, improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further illustrate the technical means and functions adopted by the present invention to achieve the purpose of the invention, the specific implementation manners of the present invention will be described below in conjunction with the drawings. The following examples serve to illustrate the invention, but do not limit the scope of the invention.

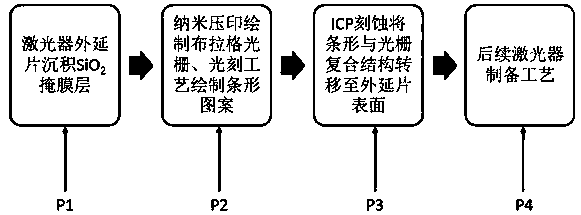

[0028] The preparation method of the GaN-based low-order surface grating DFB laser proposed by the present invention, such as figure 1 shown, including the following steps:

[0029] Step P1, prepare the GaN-based laser epitaxial wafer, use acetone, alcohol and deionized water to ultrasonically clean and then use PECVD to deposit SiO 2 The mask is used as the substrate for backup;

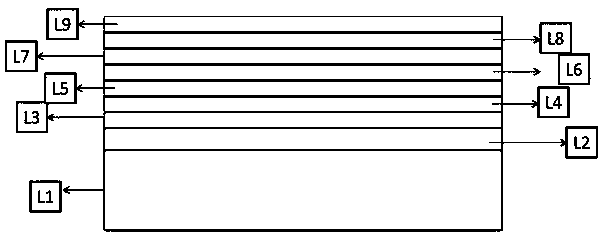

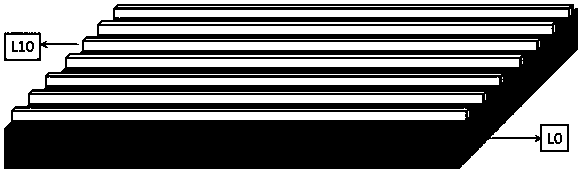

[0030] Its structure is as figure 2 As shown, the substrate used for the epitaxial wafer is an N-type GaN self-supporting substrate, and the lower confinement layer, the lower waveguide layer, the multi-quantum well active layer, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com