Water-soluble porous completely biodegradable composite material for preparing seedling container, preparation method and seedling container based on same

A seedling raising container and biodegradation technology, applied in the field of water-soluble porosity fully biodegradable composite materials and their preparation, can solve the problems of restricted root development, slow degradation rate of biodegradable resin, etc., so as to improve production and cultivation effect and production efficiency High, maneuverable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

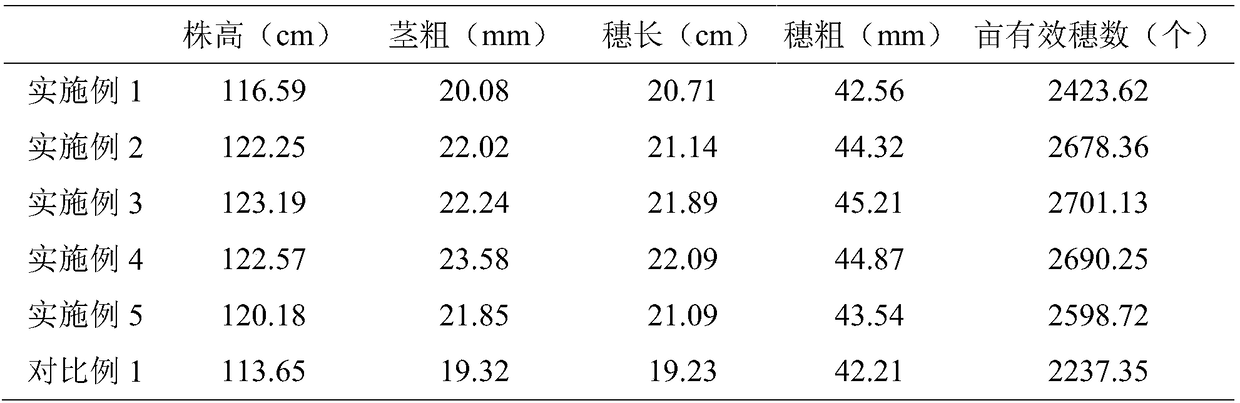

Examples

Embodiment 1

[0035] Materials: 300 parts by mass of PBAT (BASF Ecoflex), 150 parts by mass of PLA (NatureWorks 4032D), 200 parts by mass of thermoplastic starch (Wuhan Huali Environmental Technology Co., Ltd.), 200 parts by mass of KH550 modified bagasse, potassium nitrate (Tianjin Damao Chemical Reagent Company) 50 mass parts, thermoplastic polyvinyl alcohol (Weifang Huawei New Material Technology Co., Ltd.) 50 mass parts, antioxidant 1010 (Germany BASF) 10 mass parts, stearic acid (Tianjin Damao Chemical Reagent Company) 10 parts by mass, 10 parts by mass of CBT (Wuhan Hyperbranched Resin Co., Ltd.), 20 parts by mass of talcum powder (Guangzhou Huajun Talc Powder Co., Ltd.).

[0036] Premix: (1) Put thermoplastic starch and modified bagasse into a high-speed mixer and mix for 5 minutes at 200r / min; (2) Mix potassium nitrate, thermoplastic polyvinyl alcohol, antioxidant 1010, stearin Acid, CBT, and talcum powder are mixed slightly first, and then slowly added to the premix in step (1) tha...

Embodiment 2

[0040]Materials: 200 parts by mass of PBAT (BASF Ecoflex), 50 parts by mass of PLA (NatureWorks 4032D), 300 parts by mass of thermoplastic starch (Wuhan Huali Environmental Protection Technology Co., Ltd.), 300 parts by mass of KH550 modified bagasse (self-made), potassium nitrate (Tianjin Damao Chemical Reagent Company) 50 mass parts, thermoplastic polyvinyl alcohol (Weifang Huawei New Material Technology Co., Ltd.) 50 mass parts, antioxidant 1010 (Germany BASF) 10 mass parts, calcium stearate (Tianjin Damao Chemical Reagent Company) 20 parts by mass, CBT (Wuhan Hyperbranched Resin Co., Ltd.) 10 parts by mass, white carbon black (Guangzhou Huajun Talc Powder Co., Ltd.) 10 parts by mass.

[0041] Premix: (1) Put thermoplastic starch and modified bagasse into a high-speed mixer and mix for 5 minutes at 200r / min; (2) Mix thermoplastic polyvinyl alcohol, potassium nitrate, antioxidant 1010, stearin Calcium acid, CBT, and white carbon black are mixed slightly first, and then slowl...

Embodiment 3

[0045] Materials: 200 parts by mass of PBAT (BASF Ecoflex), 50 parts by mass of PLA (NatureWorks 4032D), 300 parts by mass of thermoplastic starch (Wuhan Huali Environmental Protection Technology Co., Ltd.), 300 parts by mass of KH550 modified bagasse (self-made), potassium nitrate (Tianjin Damao Chemical Reagent Company) 80 mass parts, thermoplastic polyvinyl alcohol (Weifang Huawei New Material Technology Co., Ltd.) 20 mass parts, antioxidant 1010 (Germany BASF) 10 mass parts, calcium stearate (Tianjin Damao Chemical Reagent Company) 20 parts by mass, CBT (Wuhan Hyperbranched Resin Co., Ltd.) 10 parts by mass, white carbon black (Guangzhou Huajun Talc Powder Co., Ltd.) 10 parts by mass.

[0046] Premix: (1) Put thermoplastic starch and modified bagasse into a high-speed mixer and mix for 5 minutes at 200r / min; (2) Mix thermoplastic polyvinyl alcohol, potassium nitrate, antioxidant 1010, stearin Calcium acid, CBT, and white carbon black are mixed slightly first, and then slow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com