Method for preparing activated sludge cuprous oxide composite material by using kandelia candel hypocotyl extract

A technology of activated sludge and cuprous oxide, which is applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc. The effect of short processes, high environmental benefits and economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

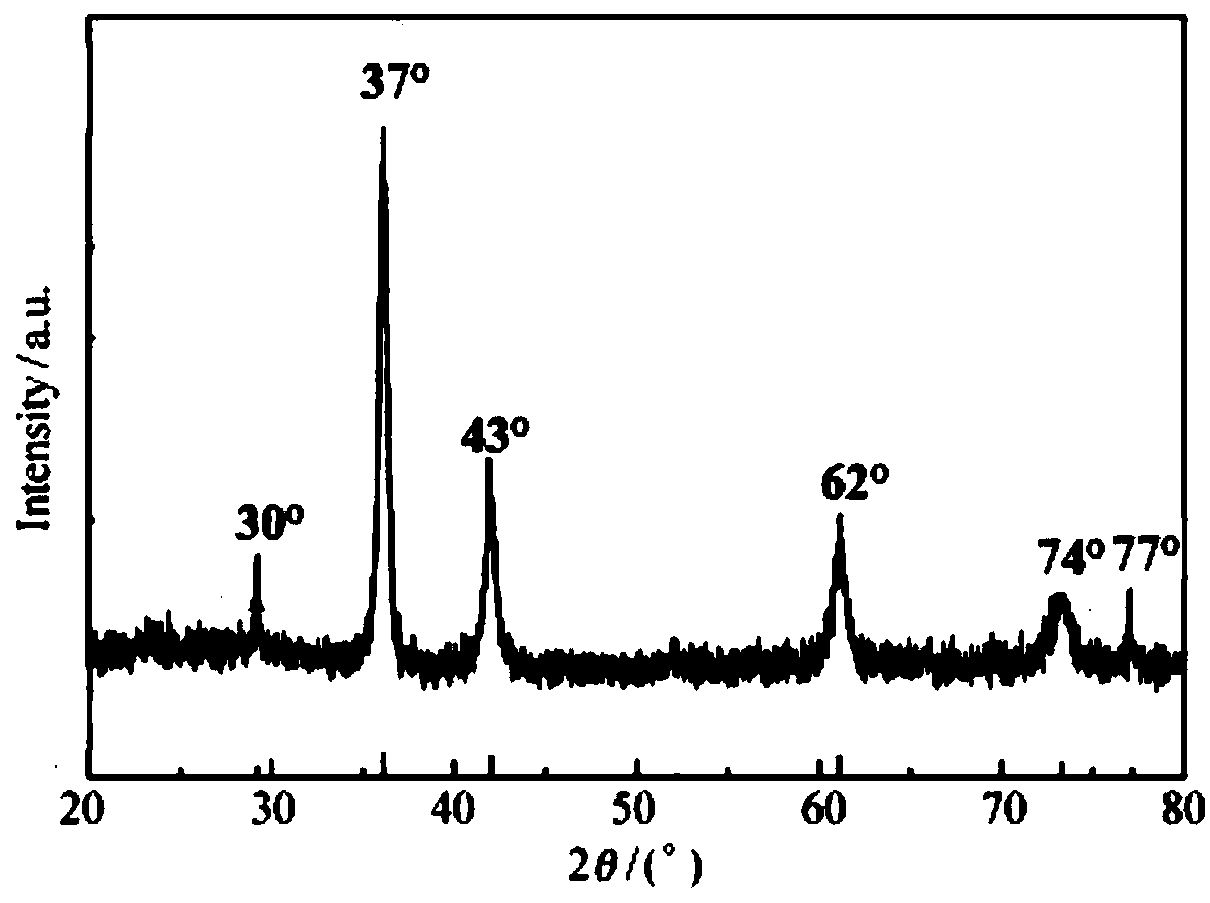

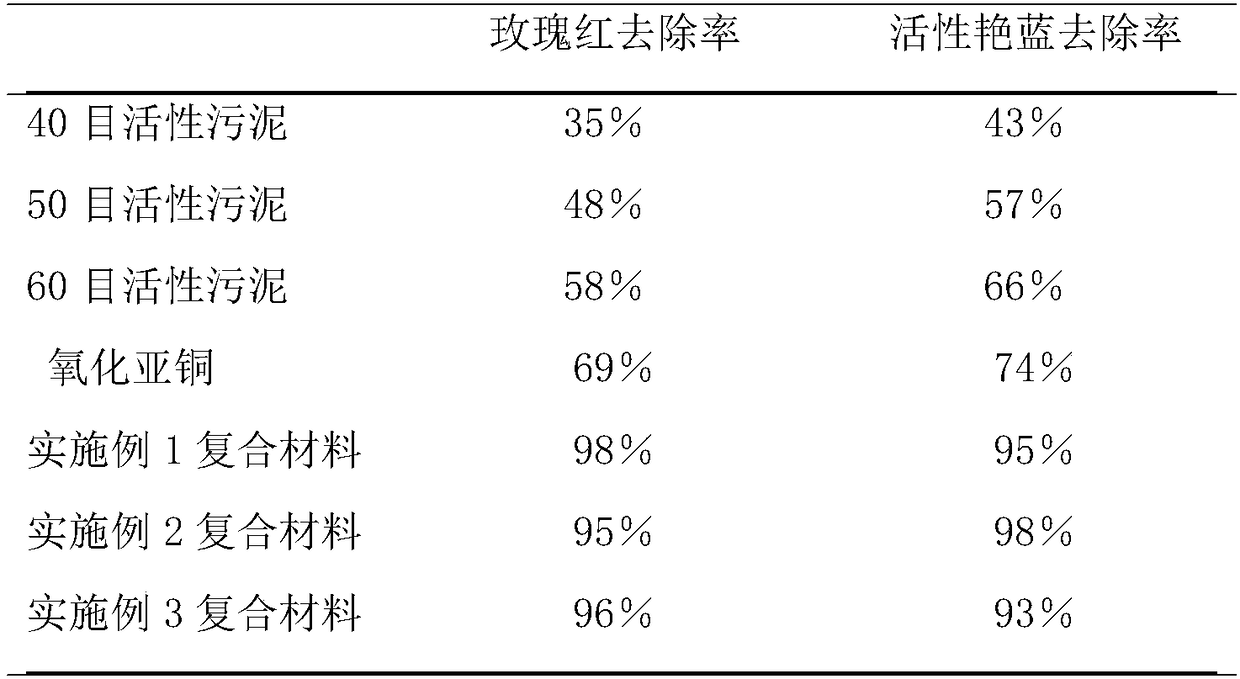

[0031] Using activated sludge as a carrier, the activated sludge cuprous oxide composite material is synthesized and prepared by using polyphenols, flavonoids, caffeine and other biologically active reducing agents contained in the candela hypocotyl extract. The specific implementation steps are:

[0032] The activated sludge from Zhangzhou domestic sewage treatment plant was dried in an oven at 105°C for 20 hours, then crushed and passed through a 60-mesh sieve. The sieved activated sludge is soaked in 2mL of 0.1mol / L nitric acid solution per gram for 20h, filtered with suction and quickly washed with distilled water until neutral, dried in an oven at 105°C for 18h, and stored for later use.

[0033] Dissolve an appropriate amount of copper chloride dihydrate and sodium hydroxide in a certain amount of deionized water to obtain 0.2 and 0.8 mol / L mixed solutions of copper chloride and sodium hydroxide. Add 15mL mixed solution per gram of 60-mesh activated sludge, stir magnetic...

Embodiment 2

[0037] The activated sludge from the Zhangzhou domestic sewage treatment plant was dried in an oven at 105°C for 22 hours, then crushed and passed through an 80-mesh sieve. The sieved activated sludge is soaked in 2 mL of 0.2 mol / L nitric acid solution per gram for 22 hours, filtered by suction and quickly washed with distilled water until neutral, dried in an oven at 110°C for 20 hours, and stored for later use.

[0038] Dissolve an appropriate amount of copper chloride dihydrate and sodium hydroxide in a certain amount of deionized water to obtain 0.3 and 1.0 mol / L mixed solutions of copper chloride and sodium hydroxide. Add 20mL mixed solution per gram of 80-mesh activated sludge, stir magnetically for 8 hours, filter and wash quickly with deionized water until no copper ions are detected in the filtrate, and dry in an oven at 110°C for 20 hours to obtain copper-loaded activated sludge. .

[0039] The collected candela hypocotyls were removed from impurities, cleaned with ...

Embodiment 3

[0042] The activated sludge from the Zhangzhou domestic sewage treatment plant was dried in an oven at 105°C for 24 hours, then crushed and passed through a 100-mesh sieve. The sieved activated sludge is soaked in 3 mL of 0.2 mol / L nitric acid solution per gram for 24 hours, filtered by suction and quickly washed with distilled water until neutral, dried in an oven at 105°C for 20 hours, and stored for later use.

[0043] Dissolve an appropriate amount of copper chloride dihydrate and sodium hydroxide in a certain amount of deionized water to obtain 0.4 and 1.0 mol / L copper chloride and sodium hydroxide solutions. Add 30mL mixed solution per gram of 100-mesh activated sludge, stir magnetically for 7 hours, filter with suction and wash quickly with deionized water until no copper ions are detected in the filtrate, and dry in an oven at 105°C for 19 hours to obtain copper-loaded activated sludge. .

[0044] The collected candela hypocotyls were removed from impurities, cleaned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com