Casein-based packaging film, preparation method thereof and application of casein-based packaging film in preservation of cured meat

A technology for packaging film and casein, which is applied to the preservation of meat/fish with chemicals and the preservation of meat/fish with a protective layer, which can solve the problems affecting food quality and nutrition, food poisoning, etc., and achieve good biological stability , low price, excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

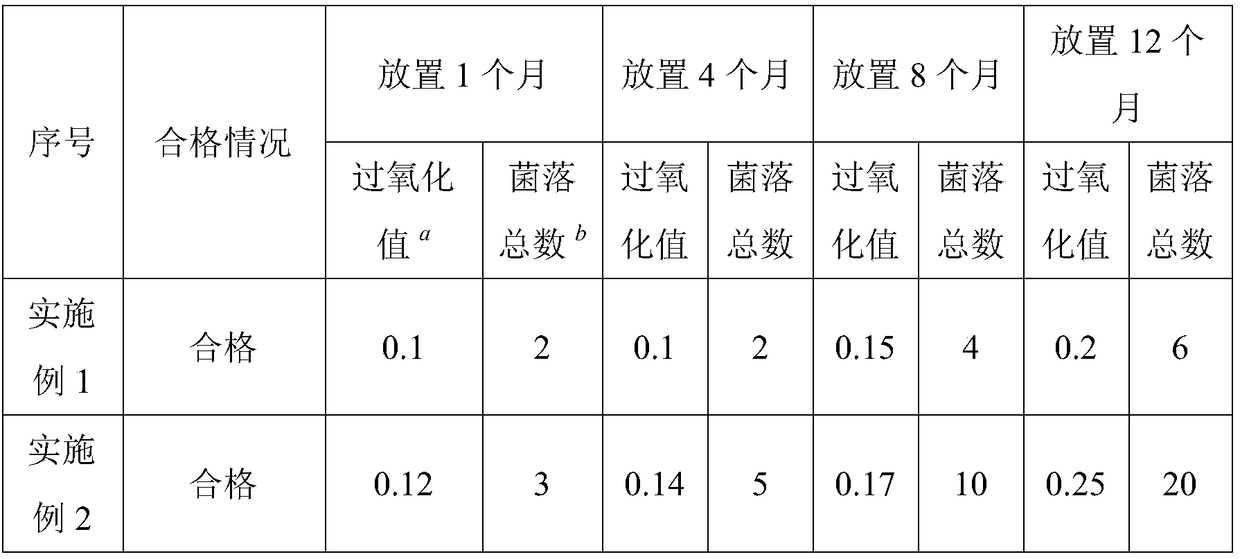

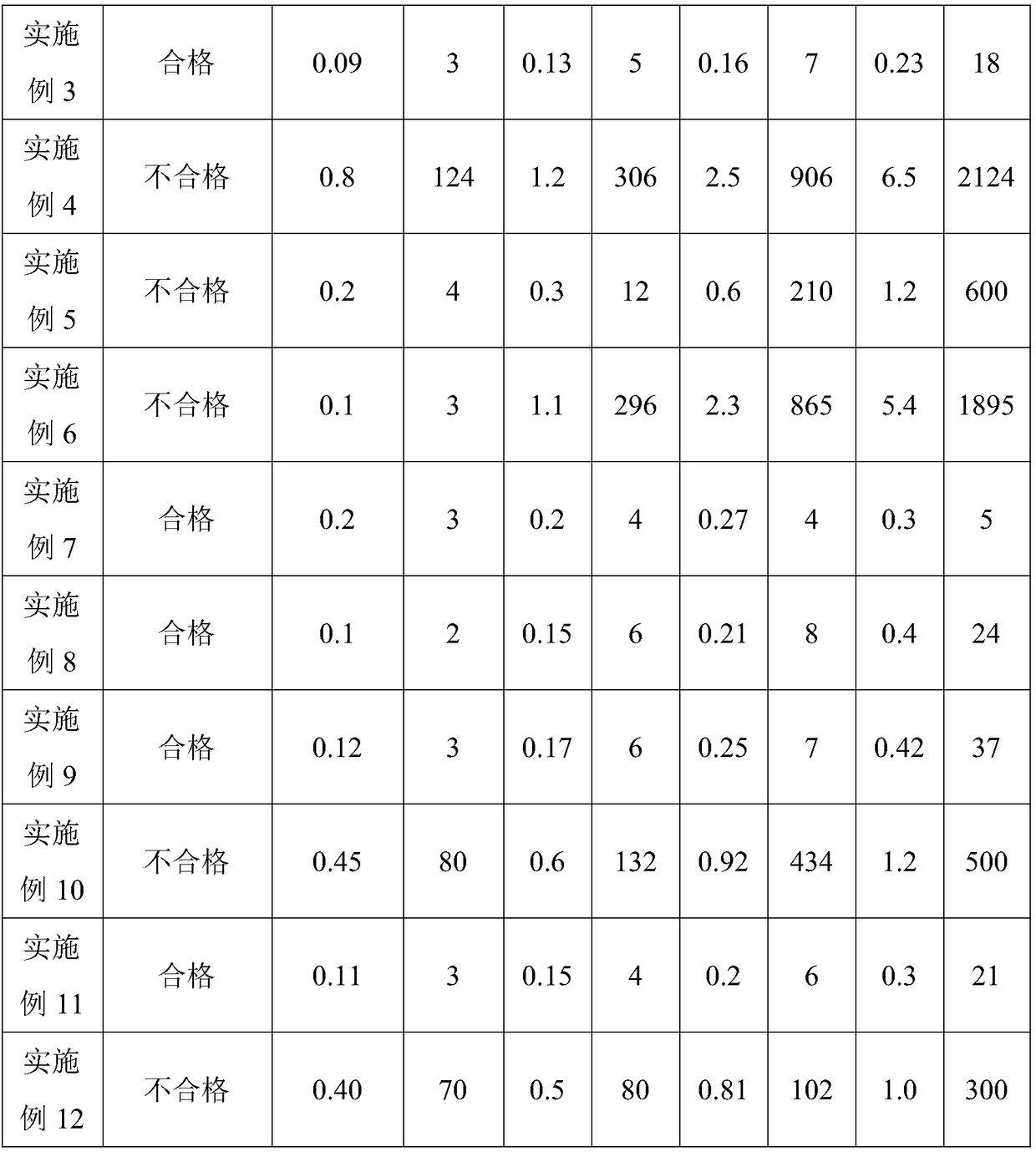

Examples

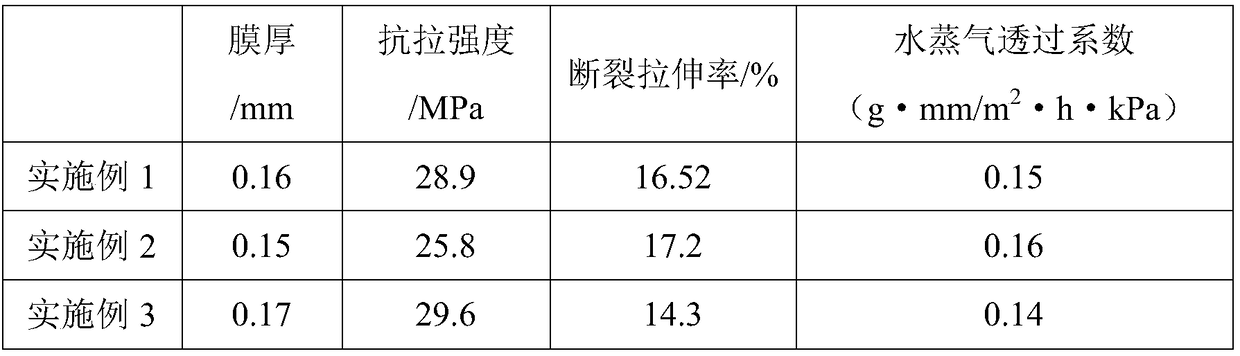

Embodiment 1

[0033]In Example 1, first, 10 g of casein powder was dispersed in 50 mL of 0.2 mol / L NaOH solution, and after mechanical stirring for 30 min, a 0.2 g / mL casein solution was prepared. In addition, 2 g of halloysite was dispersed in 10 mL of deionized water, magnetically stirred at a stirring rate of 42 r / min for 5 min, and then ultrasonicated at an ultrasonic frequency of 28 KHZ for 30 min to prepare a suspension of halloysite. Then mix the prepared clay suspension with the casein solution and stir until well mixed. Weigh 0.005g nisin and 1g glycerin and add dropwise in the mixed solution, mechanically stir for 5min, after the solution is uniformly dispersed, finally drop the mixed solution (2g of ethylene glycol diglycidyl ether and 0.5g butyl dianhydride) to prepare a coating solution.

[0034] ① Soak the smoked bacon in the film-forming solution for 1 min, take it out, and dry it at room temperature and pressure for 48 hours.

[0035] ② Take the film solution and scrape it...

Embodiment 2

[0037] In Example 2, firstly, 10 g of casein powder was dispersed in 50 mL of 0.2 mol / L NaOH solution, and after mechanical stirring for 30 min, a 0.2 g / mL casein solution was prepared. In addition, 1 g of halloysite was dispersed in 10 mL of deionized water, stirred magnetically at a stirring rate of 42 r / min for 5 min, and then ultrasonicated at an ultrasonic frequency of 28 KHZ for 30 min to prepare a suspension of halloysite. Then mix the prepared clay suspension with the casein solution and stir until well mixed. Weigh 0.004g nisin and 1g glycerin and add dropwise in the mixed solution, mechanically stir for 5min, after the solution is uniformly dispersed, finally drop the mixed solution (1.5g of ethylene glycol diglycidyl ether and 0.5g succinic anhydride) to prepare a coating solution.

[0038] ① Soak the smoked bacon in the film-forming solution for 1 min, take it out, and dry it at room temperature and pressure for 48 hours.

[0039] ② Take the film solution and scr...

Embodiment 3

[0041] In Example 3, first, 10 g of casein powder was dispersed in 50 mL of 0.2 mol / L NaOH solution, and after mechanical stirring for 30 min, a 0.2 g / mL casein solution was prepared. In addition, 3 g of halloysite was dispersed in 10 mL of deionized water, stirred magnetically at a stirring rate of 42 r / min for 5 min, and then ultrasonicated at an ultrasonic frequency of 28 KHZ for 30 min to prepare a suspension of halloysite. Then mix the prepared clay suspension with the casein solution and stir until well mixed. Weigh 0.008g nisin and 1g glycerin and add dropwise in the mixed solution, mechanically stir for 5min, after the solution is uniformly dispersed, finally add the mixed solution dropwise at a rate of 0.07g / min (2.5g of ethylene glycol diglycidyl ether and 0.5g succinic anhydride) to prepare a coating solution.

[0042] ① Soak the smoked bacon in the film-forming solution for 1 min, take it out, and dry it at room temperature and pressure for 48 hours.

[0043] ② T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com