A magnetic core/shell structured ti 3 c 2 Alkene/ni powder and preparation method thereof

A technology of shell structure and powder, applied in metal processing equipment, liquid chemical plating, transportation and packaging, etc., to achieve the effect of easy collection and cleaning, large specific surface area and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

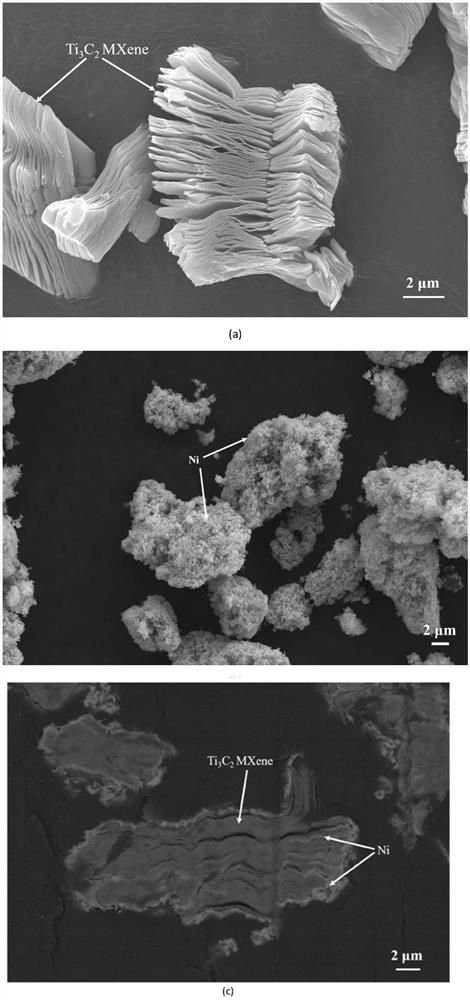

Image

Examples

Embodiment approach 1

[0029] 1. Reagent ingredients:

[0030] Activation solution: 1g / L PbCl 2 , 50g / L SnCl 2 , 5g / L NaCl, 30mL / L HCl (6M) were added into water to make a colloidal palladium solution.

[0031] Degumming solution: 5% HCl solution.

[0032]Electroless plating solution: 10g / L nickel sulfate hexahydrate, 10g / L disodium edetate, 10g / L disodium citrate, 10mg / L thiourea, adjust the pH of the plating solution to 9-10 with NaOH solution.

[0033] Reducing agent: 100ml / L 80% hydrazine hydrate.

[0034] 2. Electroless plating:

[0035] (1) Put Ti 3 C 2 Put the powder into the colloidal palladium solution, continue magnetic stirring at 60°C for 30min, and then centrifuge to separate the activated Ti 3 C 2 For the powder, use the prepared dilute HCl solution to degumming for 1min. For Ti after degelling 3 C 2 The powder was centrifugally cleaned until the pH value was about 7, and then the powder was dried in a vacuum drying oven at 60°C for 24 hours to obtain Ti 3 C 2 Activated po...

Embodiment approach 2

[0041] 1. Reagent ingredients:

[0042] Activation solution: 1g / L PbCl 2 , 100g / L SnCl 2 , 10g / L NaCl, 50mL / L HCl (6M) were added into water to make colloidal palladium solution.

[0043] Degumming solution: 8% HCl solution.

[0044] Electroless plating solution: 20g / L nickel sulfate hexahydrate, 15g / L disodium edetate, 15g / L disodium citrate, 20mg / L thiourea, adjust the pH of the plating solution to 10-11 with NaOH solution.

[0045] Reducing agent: 150ml / L 80% hydrazine hydrate.

[0046] 2. Electroless plating:

[0047] (1) Put Ti 3 C 2 Put the powder into the colloidal palladium solution, continue magnetic stirring at 60°C for 90min, and then centrifuge to separate the activated Ti 3 C 2 For the powder, use the prepared dilute HCl solution to degumming for 2 minutes. For Ti after degelling 3 C 2 The powder was centrifugally cleaned until the pH value was about 7, and then the powder was dried in a vacuum drying oven at 60°C for 24 hours to obtain Ti 3 C 2 Activ...

Embodiment approach 3

[0053] 1. Reagent ingredients:

[0054] Activation solution: 2g / L PbCl 2 , 150g / L SnCl 2 , 20g / L NaCl, 100mL / L HCl (6M) were added into water to make colloidal palladium solution.

[0055] Degumming solution: 10% HCl solution.

[0056] Electroless plating solution: 20g / L nickel sulfate hexahydrate, 10g / L disodium edetate, 10g / L disodium citrate, 10mg / L thiourea, adjust the pH of the plating solution to 10-11 with NaOH solution.

[0057] Reducing agent: 200ml / L 80% hydrazine hydrate.

[0058] 2. Electroless plating:

[0059] (1) Put Ti 3 C 2 Put the powder into the colloidal palladium solution, continue magnetic stirring at 60°C for 60min, and then centrifuge to separate the activated Ti 3 C 2 For the powder, use the prepared dilute HCl solution to degumming for 5 minutes. For Ti after degelling 3 C 2 The powder was centrifugally cleaned until the pH value was about 7, and then the powder was dried in a vacuum drying oven at 60°C for 24 hours to obtain Ti 3 C 2 Act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com