Porous materials incorporating carbon black thin films, their applications and methods of preparation

A technology of structural materials and thin films, applied in metal material coating process, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of limiting the popularization and application of seawater desalination technology, unsatisfactory process efficiency, low energy utilization rate, etc., to achieve Produce fresh water with high efficiency, small footprint and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

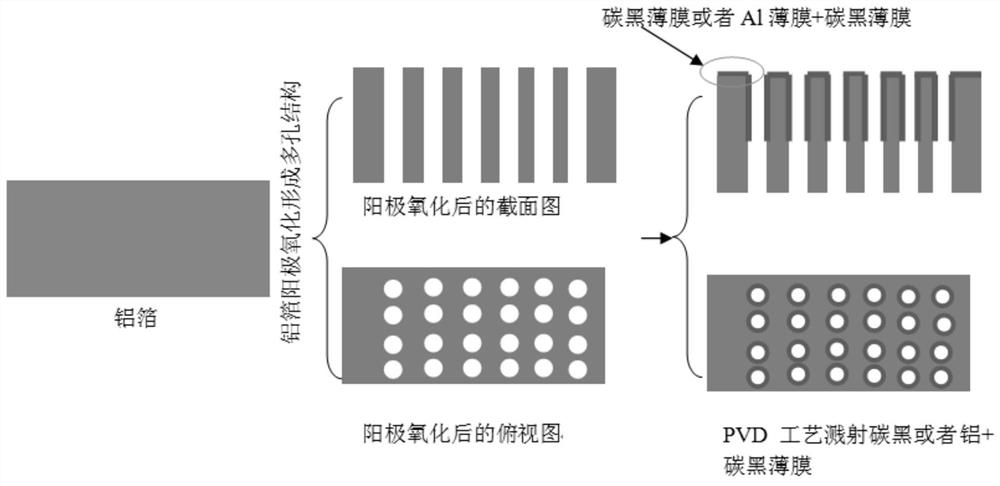

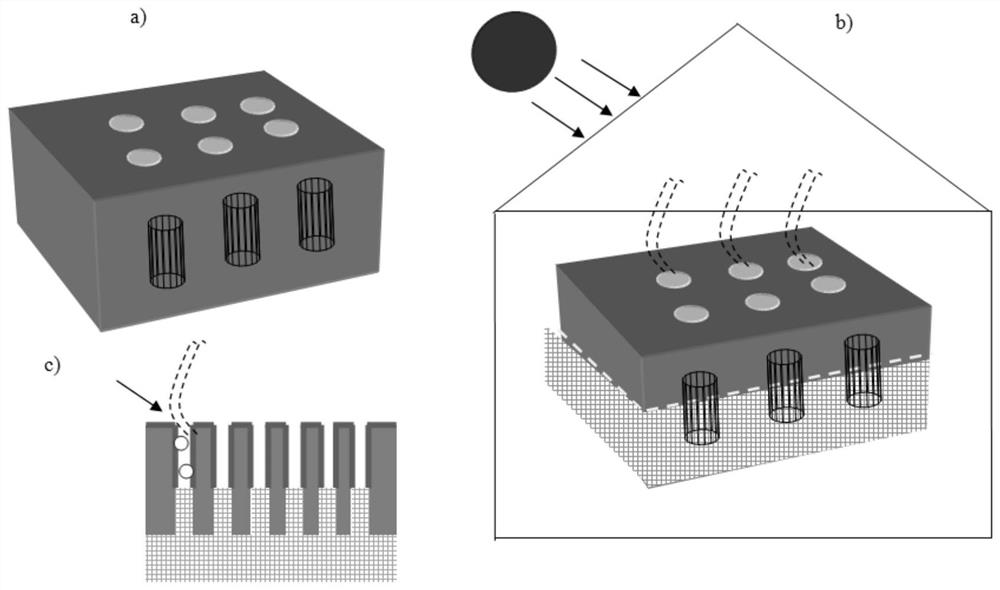

[0039] In this example, see figure 1 and figure 2 , a porous structure material with a nano-coating black film layer, using metal foil as a substrate, using anodizing process to treat the substrate, so that the surface of the substrate forms a nano-scale straight pore structure; A metal film is first deposited on the surface of the pore structure, and then a carbon black material is deposited to form a straight hole structure material having a composite material film of the metal film and the carbon black film. The metal foil used as the substrate is an Al foil made of high-purity aluminum with a purity of 99.99%. The shape of the pores of the nano-scale straight pore structure prepared by the anodization method is a vertical structure, and the size of the pores is 0.1 nanometers. The carbon black material is deposited on the surface of the straight hole to form a carbon black film with a thickness of 1 angstrom. A metal film is first deposited on the surface of the straig...

Embodiment 2

[0061] This embodiment is basically the same as the first embodiment, and the special features are:

[0062] In this embodiment, a method for preparing a porous material combined with a carbon black film includes the following steps:

[0063] a. This step is the same as the first embodiment;

[0064] b. Anodizing process is adopted. When the Al foil is treated by anodizing process, an acidic electrolyte, specifically sulfuric acid is used as the electrolyte for electrolysis; the nano-scale straight pores are formed on the surface of the Al foil by two anodic oxidation methods. Structure; when oxalic acid solution is used as electrolyte for anodic oxidation, the concentration of oxalic acid solution is 0.2~0.7mol·L -1 , the control electrolysis voltage is 40V, and the electrolysis reaction temperature is 10~25℃;

[0065] When the first anodic oxidation is carried out, the aluminum sheet is used as the anode, and the lead plate or stainless steel plate is used as the cathode. ...

Embodiment 3

[0071] This embodiment is basically the same as the previous embodiment, and the special features are:

[0072] In this embodiment, a method for preparing a porous material combined with a carbon black film includes the following steps:

[0073] a. This step is the same as the first embodiment;

[0074] b. Anodizing process is adopted. When the Al foil is treated by anodizing process, an acidic electrolyte, specifically sulfuric acid is used as the electrolyte for electrolysis; the nano-scale straight pores are formed on the surface of the Al foil by two anodic oxidation methods. Structure; when using phosphoric acid solution as electrolyte for anodic oxidation, the mass fraction of phosphoric acid solution is 10% to 30wt.%, the electrolysis voltage is controlled to be 10 to 100V, and the electrolysis reaction temperature is 10 to 20°C;

[0075]When the first anodic oxidation is carried out, the aluminum sheet is used as the anode, and the lead plate or stainless steel plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com