A new energy hybrid ship battery system

A battery system and hybrid technology, which is applied in ship propulsion, engines combined with propulsion devices, and ship construction, can solve the problems of poor blade corrosion resistance and low power generation efficiency, and achieve improved power generation efficiency and high power generation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

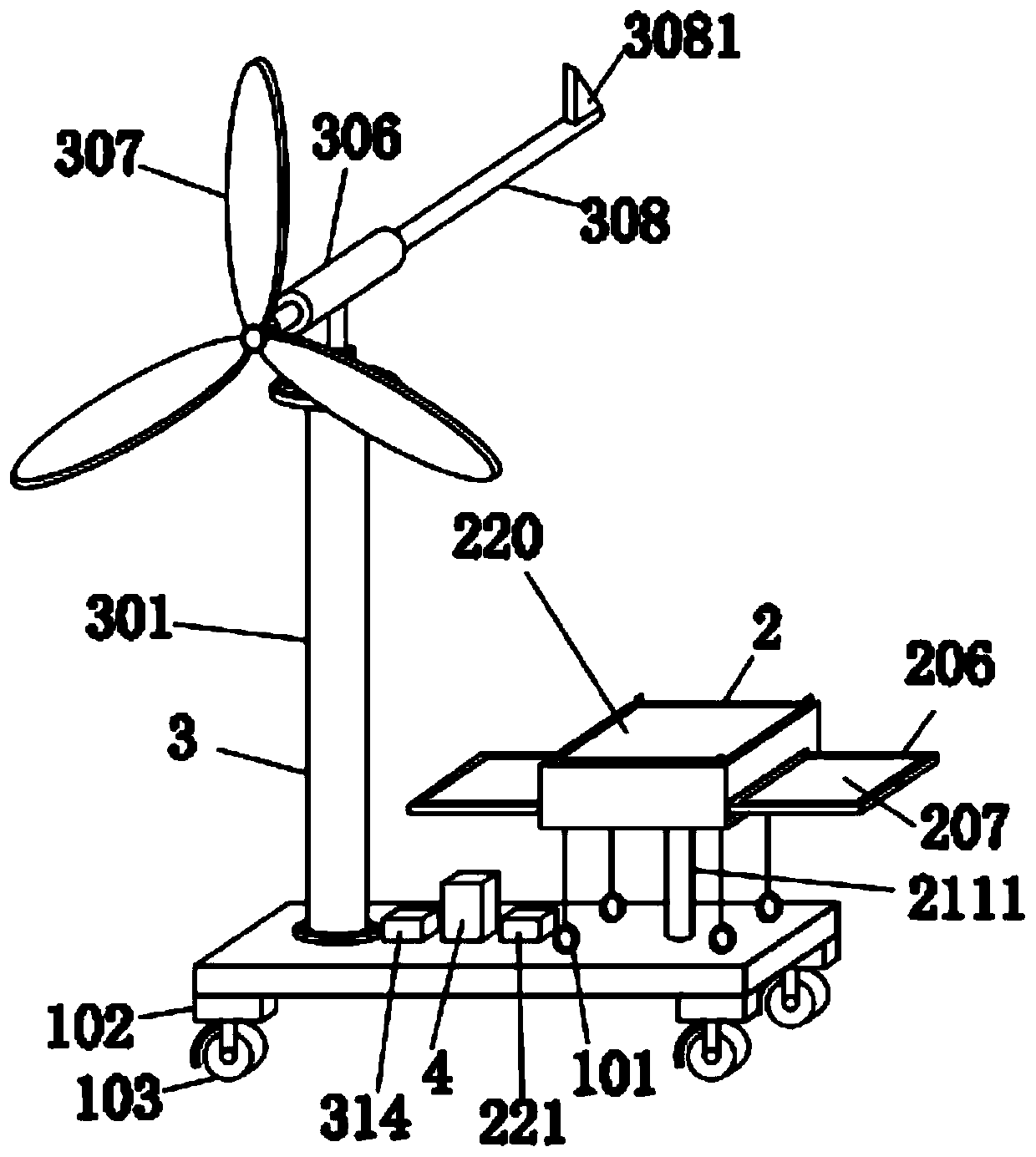

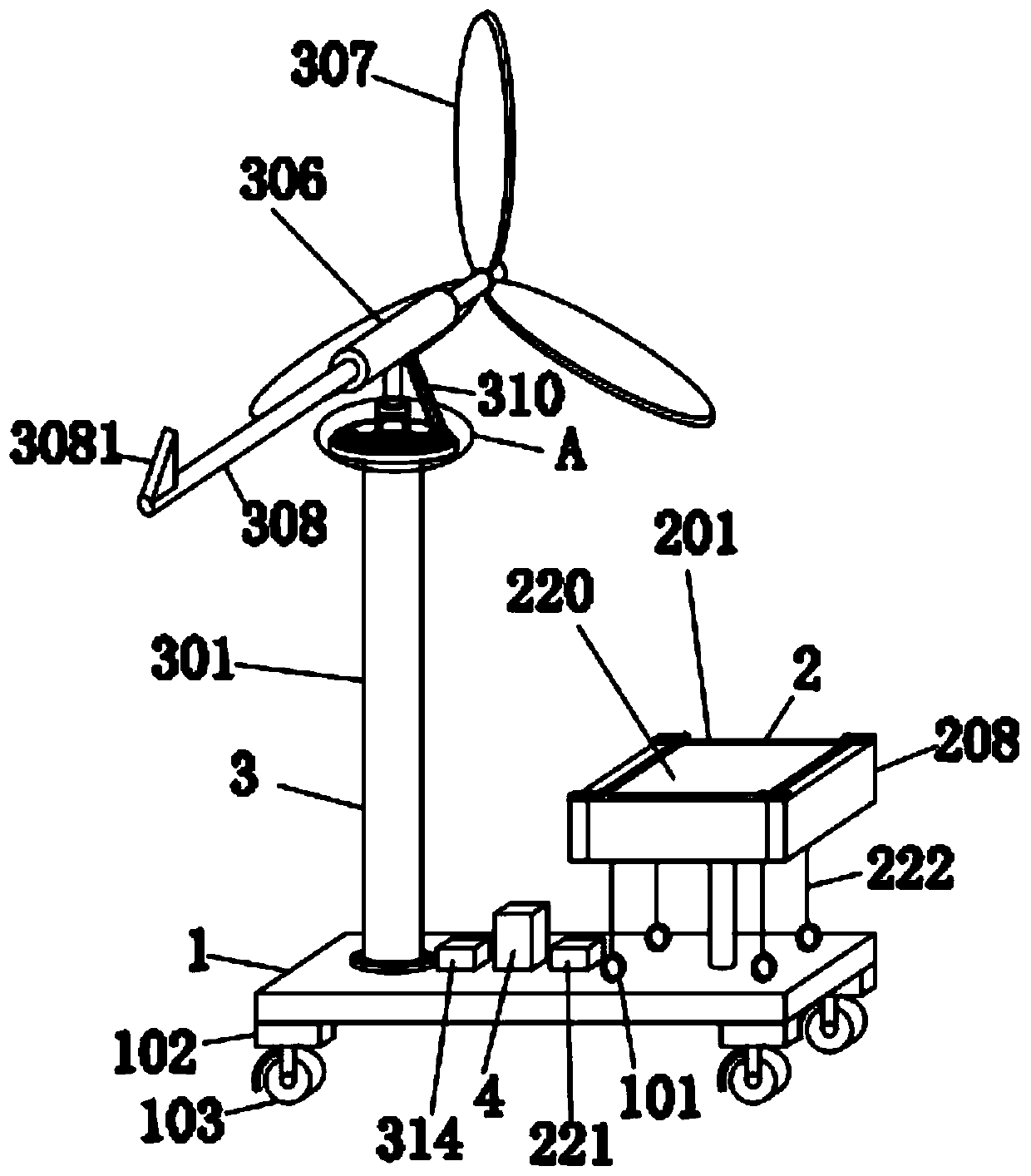

[0043] Such as figure 1 and figure 2 As shown, a new energy hybrid ship battery system includes a bottom plate 1, and a solar power generation mechanism 2 and a wind power generation mechanism 3 are arranged on the top of the bottom plate 1 in sequence from left to right;

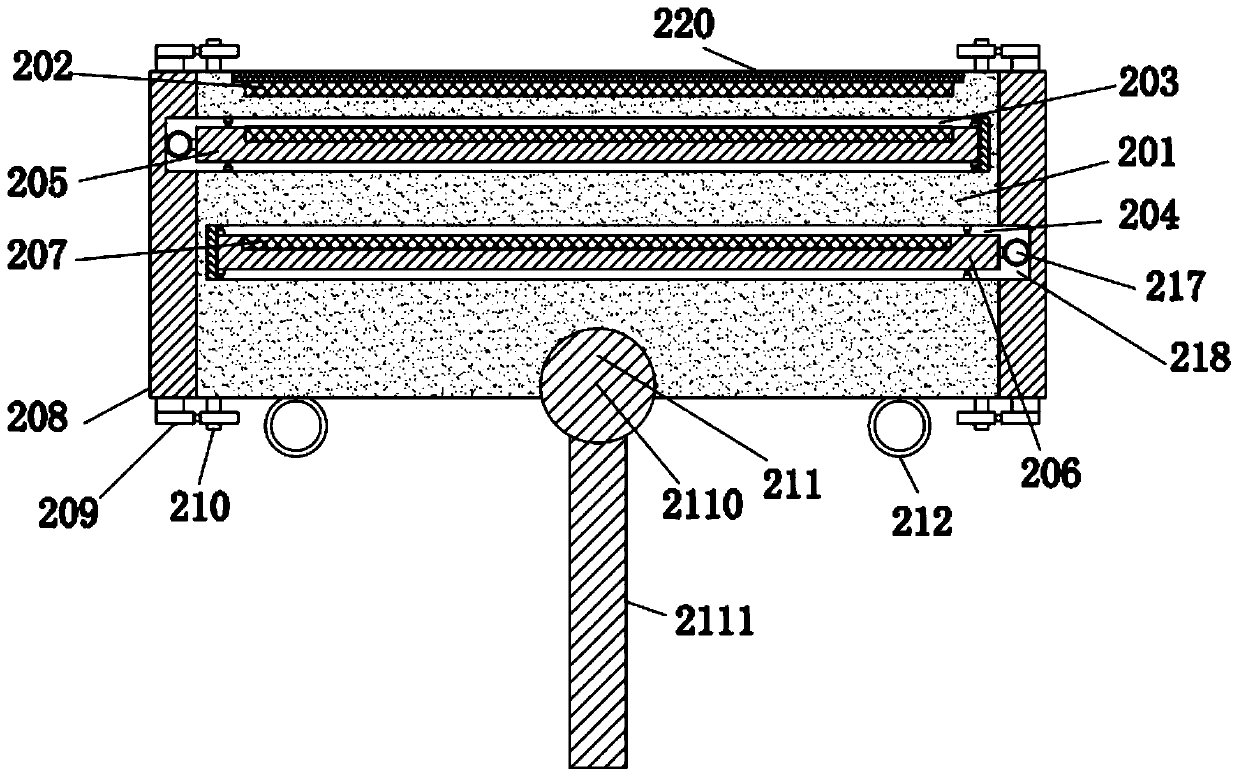

[0044] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the solar power generation mechanism 2 includes a rectangular plate 201. The inside of the rectangular plate 201 is sequentially provided with a first chute 203 and a second chute 204 from top to bottom. The first chute 203 is sealed on the left side and the right side. The second chute 204 is sealed on the left side of the opening on the right side. The inside of the first chute 203 and the second chute 204 are respectively movably inserted with a first socket board 205 and a second socket board 206. The tops of the board 205 and the second plug-in board 206 are inlaid with a second solar power generation board 207, the top of the...

Embodiment 2

[0069] The difference from Example 1 is that the outer wall of the paddle 307 is sprayed with an anti-corrosion layer, and the anti-corrosion layer is prepared by the following method:

[0070] Take the following raw materials and weigh them by weight: 3 parts of zirconia, 6 parts of boron nitride, 5 parts of silicon nitride, 6 parts of silicone modified epoxy resin, 8 parts of hydrogenated castor oil, 8 parts of talcum powder, butyl acetate 4 parts, 3 parts of defoamer, 4 parts of binder and 40 parts of distilled water;

[0071] S1, material preparation: first weigh the above-mentioned raw materials;

[0072] S2. Preliminary mixing: first add distilled water into the mixer, then pour zirconia, boron nitride, silicon nitride and silicone modified epoxy resin into the mixer in turn, and mix the materials. The mixer speed is at 30r / min, stirring at 45 degrees Celsius for 20 minutes;

[0073] S3, mixing again: after stirring with the agitator for 30 minutes, add hydrogenated ca...

Embodiment 3

[0079] The difference with embodiment 2 is the preparation of anti-corrosion layer, and its specific preparation method is as follows:

[0080] Take the following raw materials and weigh them by weight: 5 parts of zirconia, 8 parts of boron nitride, 7 parts of silicon nitride, 8 parts of silicone modified epoxy resin, 12 parts of hydrogenated castor oil, 12 parts of talcum powder, butyl acetate 6 parts, 5 parts of defoamer, 7 parts of binder and 60 parts of distilled water;

[0081] S1, material preparation: first weigh the above-mentioned raw materials;

[0082] S2. Preliminary mixing: first add distilled water into the mixer, then pour zirconia, boron nitride, silicon nitride and silicone modified epoxy resin into the mixer in turn, and mix the materials. The mixer speed is at 50r / min, the temperature was stirred at 45 degrees Celsius for 20 minutes;

[0083] S3, mixing again: after stirring with the agitator for 30 minutes, add hydrogenated castor oil, talcum powder and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com