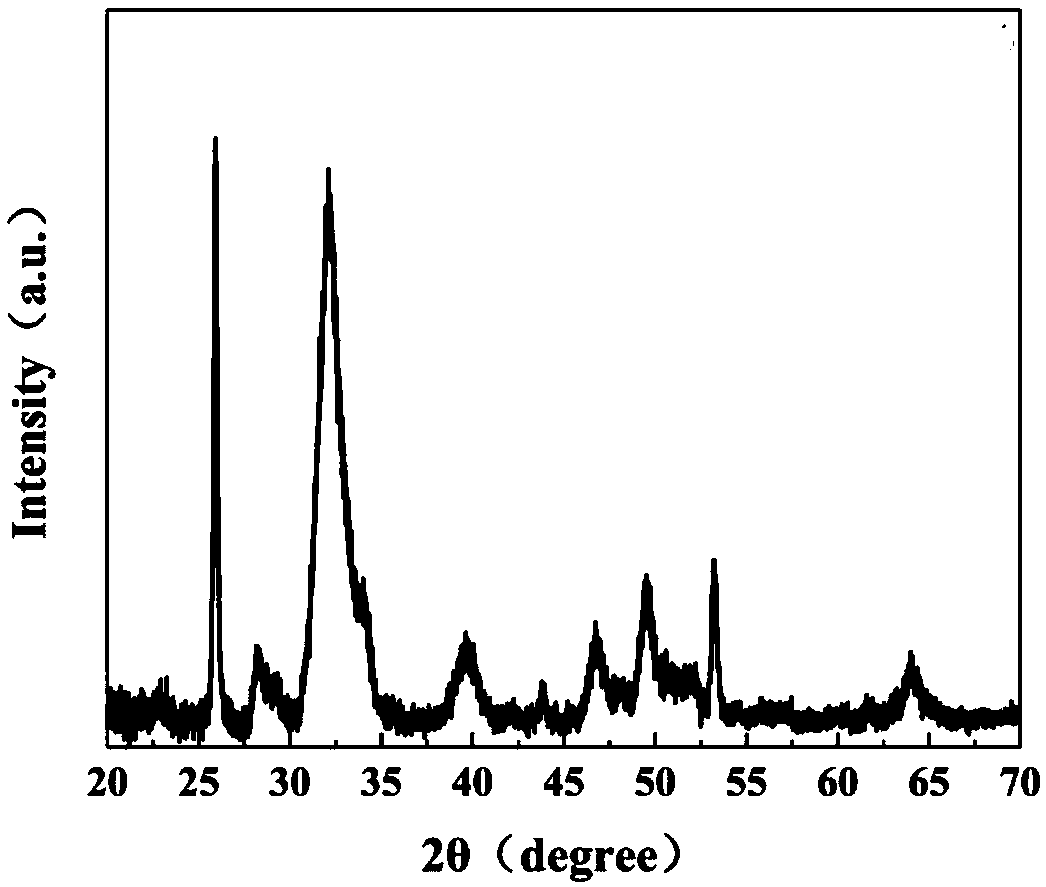

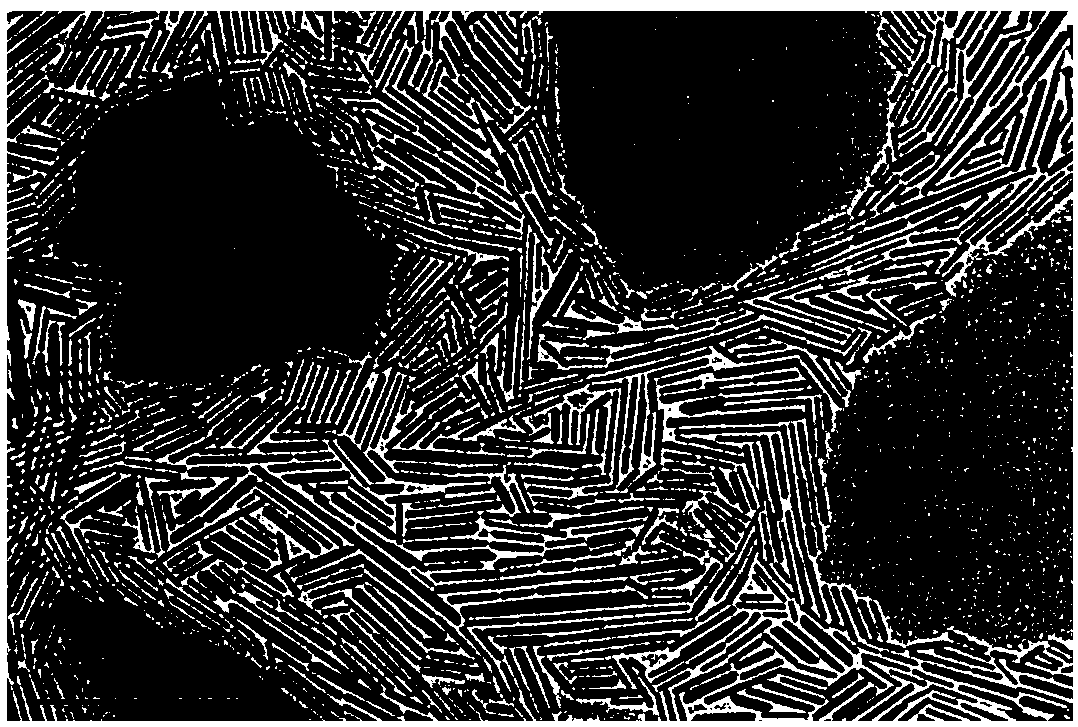

Method for preparing oil-soluble hydroxyapatite nanorod through one-step method

A hydroxyapatite, oil-soluble technology, applied in the field of one-step preparation of oil-soluble hydroxyapatite nanorods, can solve the problem of nanocrystal crystallinity, shape, size deficiency, material application can not be fully realized, oil phase dispersion effect Unsatisfactory and other problems, to achieve the effect of good shape controllability, good dispersion and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Dissolve 0.02mol calcium nitrate in 20 grams of water to obtain solution A;

[0036] 2) Dissolve 0.032 mol of ethylenediamine in a mixture of 40 g of ethanol and 0.04 mol of oleic acid to obtain solution B;

[0037] 3) Add solution B obtained in step 2) into a three-necked flask, then slowly drop solution A obtained in step 1) into solution B, and stir for 10 minutes to obtain solution C;

[0038] The mol ratio of described oleic acid and calcium is 2:1;

[0039] The molar ratio of oleic acid to ethylenediamine is 5:4.

[0040] 4) 0.012mol trisodium phosphate was dissolved in 30 grams of water to obtain solution D;

[0041] 5) Under stirring conditions, slowly drop the solution D obtained in step 4) into the solution C obtained in step 3), and continue stirring for 20 minutes after the dropwise addition to obtain a suspension;

[0042] 6) slowly drop 0.012mol sodium hydroxide solution into the suspension, and stir for 10 minutes to obtain a mixed solution;

[004...

Embodiment 2

[0047] Embodiment 2, with embodiment 1, difference is,

[0048] 1) Dissolve 0.02mol calcium nitrate in 20 grams of water to obtain solution A;

[0049] 2) Dissolve 0.016 mol of ethylenediamine in a mixture of 40 g of ethanol and 0.02 mol of oleic acid to obtain solution B;

[0050] 3) Add solution B obtained in step 2) into a three-necked flask, then slowly drop solution A obtained in step 1) into solution B, and stir for 10 minutes to obtain solution C;

[0051] The mol ratio of described oleic acid and calcium is 1:1;

[0052] The molar ratio of oleic acid to ethylenediamine is 5:4.

[0053] 4) 0.012mol trisodium phosphate was dissolved in 30 grams of water to obtain solution D;

[0054]6) slowly drop 0.008mol sodium hydroxide solution into the suspension obtained in step 5), and stir for 10 minutes to obtain a mixed solution;

[0055] 7) Put the mixed solution obtained in step 6) in a high-temperature and high-pressure reactor, heat it with water at 180° C. for 3 hours,...

Embodiment 3

[0056] Embodiment 3, with embodiment 1, difference is,

[0057] 1) Dissolve 0.02mol calcium chloride in 20 grams of water to obtain solution A;

[0058] 2) Dissolve 0.016mol of sodium hydroxide in a mixed solution of 40 grams of ethanol and 0.02mol of oleic acid to obtain solution B;

[0059] 3) Add solution B obtained in step 2) into a three-necked flask, then slowly drop solution A obtained in step 1) into solution B, and stir for 10 minutes to obtain solution C;

[0060] The mol ratio of described oleic acid and calcium is 1:1;

[0061] The mol ratio of described oleic acid and sodium hydroxide is 5:4.

[0062] 4) Dissolve 0.012mol sodium dihydrogen phosphate in 30 grams of water to obtain solution D;

[0063] 6) slowly drop 0.008mol potassium hydroxide solution into the suspension obtained in step 5), and stir for 10 minutes to obtain a mixed solution;

[0064] 7) Put the mixed solution obtained in step 6) in a high-temperature and high-pressure reactor, heat it under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com