Preparation method of biostimulant and application thereof

A biostimulant and crop technology, applied in the direction of fertilizers, applications, and fertilizer mixtures made from biological waste, can solve the problems of rare invention patents, achieve low application costs, simple cultivation and production processes, and improve plant resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A biostimulant obtained by the following steps: taking 3% to 5% EM stock solution, 2% to 5% brown sugar, 5% to 10% 20% calcium magnesium phosphate fertilizer suspension, 0.5% to 1 % of protein powder and 79% to 89.5% of deionized water are mixed evenly, and placed in a rotary shaker at a speed of 120r / min to 180r / min under airtight conditions at room temperature for anaerobic fermentation at 35 to 37°C for 5-7 days. Stand still, take the supernatant and further filter to separate the solid from the liquid, concentrate the filtrate for 35 to 60 minutes at a temperature of 50 to 75°C and a pressure of -1.5 to -0.5 MPa, and spray dry the concentrate to obtain biostimulant.

[0028] The 20% calcium magnesium phosphate fertilizer suspension is to weigh 200 grams of industrial calcium magnesium phosphate fertilizer in a 500 milliliter beaker, add deionized water and heat to dissolve, and finally settle to a 1000 milliliter volumetric flask.

[0029] The brown sugar and prote...

Embodiment 2

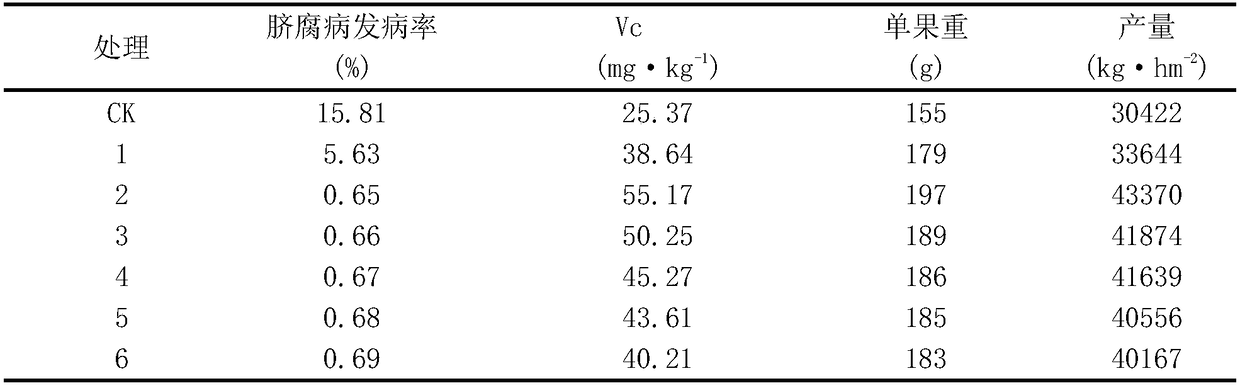

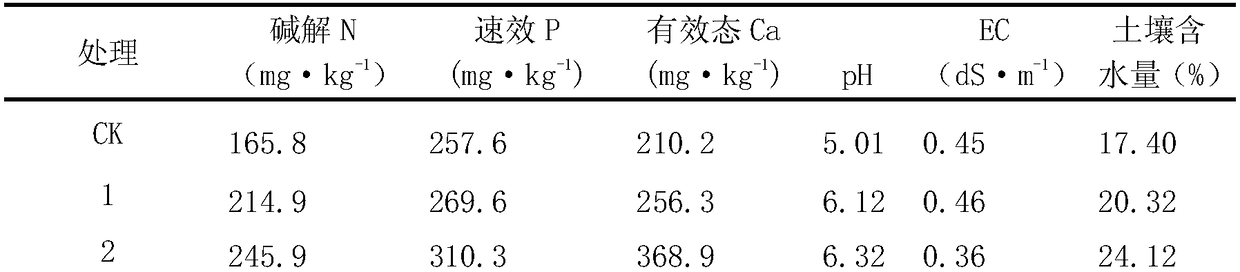

[0031]Mix the stock solution of EM bacteria, molasses, 20% calcium magnesium phosphate fertilizer suspension, protein powder, and deionized water at 5%: 5%: 6%: 1%: 83%, and put them in at 35°C under airtight conditions. Anaerobic fermentation on a rotary shaker at 150r / min for 7 days, the solid and liquid were separated by standing and filtering, and the supernatant was taken at a temperature of 55°C and a pressure of -1.5MPa, and the filtrate was concentrated for 60 minutes. The liquid is spray-dried to obtain a biostimulant containing active substances and complex microorganisms. In order to verify the effect of biostimulants, and to evaluate their effects on tomato navel rot control and yield increase, a field experiment was carried out in the greenhouse of Nanjing Institute of Vegetable Science. The soil texture is heavy loam, and the tested tomato variety is "Yingshi Dahong". The seedlings were raised in the greenhouse using plug-in substrates, and the plants were plante...

Embodiment 3

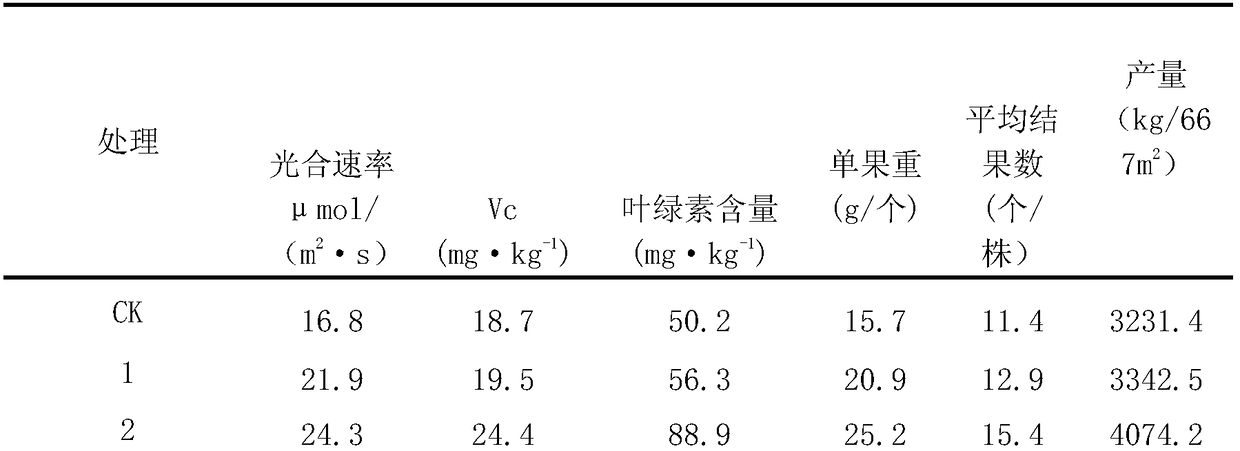

[0043] Mix the stock solution of EM bacteria, molasses, 20% calcium magnesium phosphate fertilizer suspension, protein powder, and deionized water at 4%: 4%: 8%: 0.8%: 83.2%, and put them in at 37°C under airtight conditions. Anaerobic fermentation on a rotary shaker at 180r / min for 5 days, solid-liquid separation by standing and filtering, concentration of the filtrate for 60 minutes at a temperature of 65°C and a pressure of -1.0MPa, and spray drying of the concentrate. That is, a biostimulant containing active substances and complex microorganisms is obtained. The green pepper plot experiment was carried out in the greenhouse of the Nanjing Institute of Vegetable Science. The soil texture is heavy loam, and the agronomic measures such as fertilization and irrigation between the acidification and salt preparation treatments are consistent with the field management. The experiment set up 3 treatments, each The treatments were repeated 3 times and arranged in random blocks. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com