Acetylated cellulose nanocrystal prepared through organic acid catalysis one-pot method

A cellulose and organic acid technology, applied in the field of functionalized polymer materials, can solve the problems of poor dispersion of cellulose nanocrystals, easy to agglomerate, etc., and achieve good degradability, good biocompatibility, good atomic economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

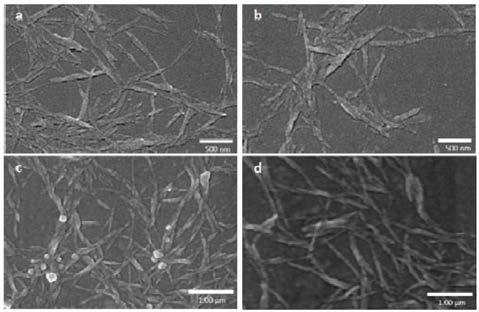

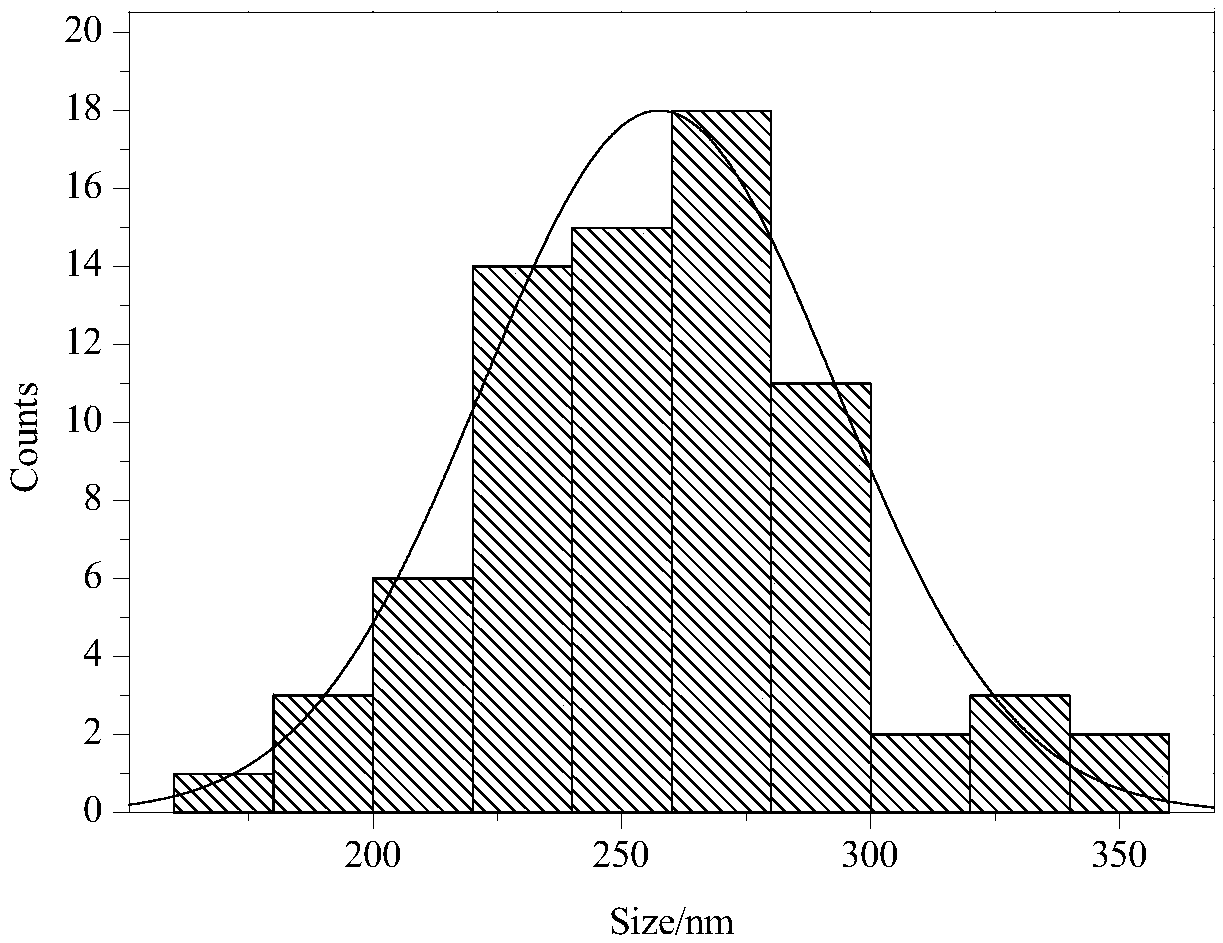

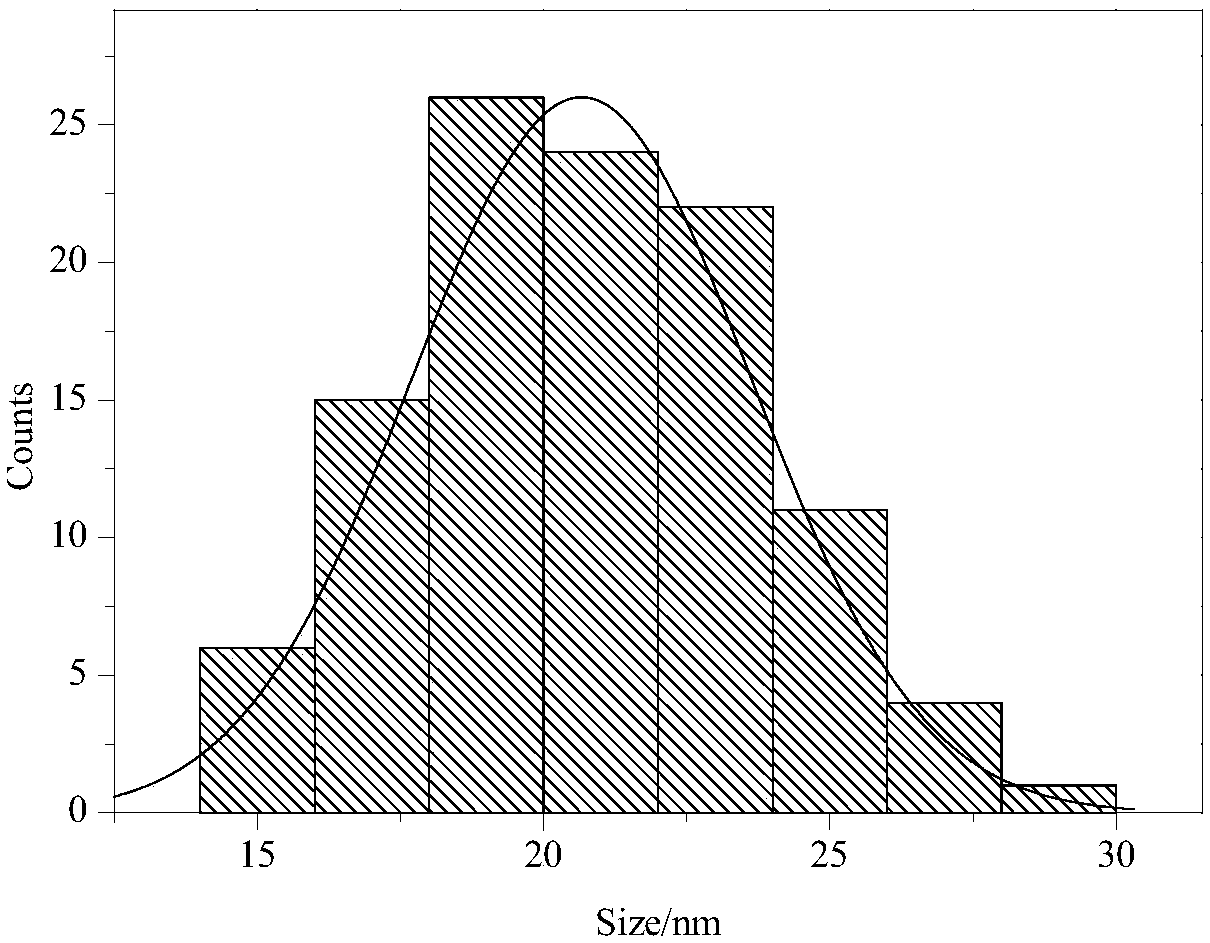

Image

Examples

Embodiment 1

[0024] (1) Pretreatment of filter paper: crush the commercially available filter paper with a paper shredder, dry it in an oven at 105°C for 3 hours, and then grind it into a floc structure with a grinder for later use.

[0025] (2) Preparation of cellulose nanocrystals: (a) Weigh 5g of p-toluenesulfonic acid, 5.55g of water, and 50g of acetic acid, mix them, and soak 5g of filter paper powder prepared in step (1) in the solution overnight. (b) Set the rotation speed at 300r / min, react in a mechanically stirred water bath at 90°C for 90min, cool in an ice bath quickly, stir in an ice water bath for 2h, and then centrifuge to recover the acid solution. (c) The obtained solid was centrifuged and washed with deionized water, and the centrifugal speed was set at 9000r / min, centrifuged for 4min, and centrifuged several times until the conductivity of the supernatant was less than 50S / m. (d) Put the obtained suspension into a 8000-14000 dialysis bag, and dialyze with deionized water...

Embodiment 2

[0028] (1) Pretreatment of filter paper: crush the commercially available filter paper with a paper shredder, dry it in an oven at 105°C for 3 hours, and then grind it into a floc structure with a grinder for later use.

[0029] (2) Preparation of cellulose nanocrystals: (a) Weigh 5g of p-toluenesulfonic acid, 6.25g of water, and 25g of acetic acid, mix them, and soak 2.5g of filter paper powder prepared in step (1) in the solution overnight. (b) Set the rotational speed at 350r / min, react in a mechanically stirred water bath at 100°C for 60min, cool in an ice bath, and stir for 2.5h in an ice-water bath, then centrifuge to recover the acid solution. (c) The obtained solid was centrifuged and washed with deionized water, and the centrifugation speed was set at 8000r / min, centrifuged for 6min, and centrifuged several times until the conductivity of the supernatant was less than 50S / m. (d) Put the obtained suspension into a 8000-14000 dialysis bag, and dialyze with deionized wat...

Embodiment 3

[0031] (1) Pretreatment of filter paper: crush the commercially available filter paper with a paper shredder, dry it in an oven at 105°C for 3 hours, and then grind it into a floc structure with a grinder for later use.

[0032] (2) Preparation of cellulose nanocrystals: (a) Weigh 5g of p-toluenesulfonic acid, 8.33g of water, and 75g of acetic acid, mix them, and soak 7.5g of filter paper powder prepared in step (1) in the solution overnight. (b) Set the rotational speed at 400r / min, react in a mechanically stirred water bath at 80°C for 120min, cool in an ice bath, and stir for 3h in an ice-water bath, then centrifuge to recover the acid solution. (c) The obtained solid was centrifuged and washed with deionized water, and the centrifugation speed was set to 7000r / min, centrifuged for 8min, and centrifuged several times until the conductivity of the supernatant was less than 50S / m. (d) Put the obtained suspension into a 8000-14000 dialysis bag, and dialyze with deionized water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap