Preparation method of capric acid

A technology of n-decanoic acid and trifluoromethanesulfonate, applied in the field of n-decanoic acid preparation, which can solve the problems of high environmental requirements for fermentation enzyme activity, limited application range, harsh reaction conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

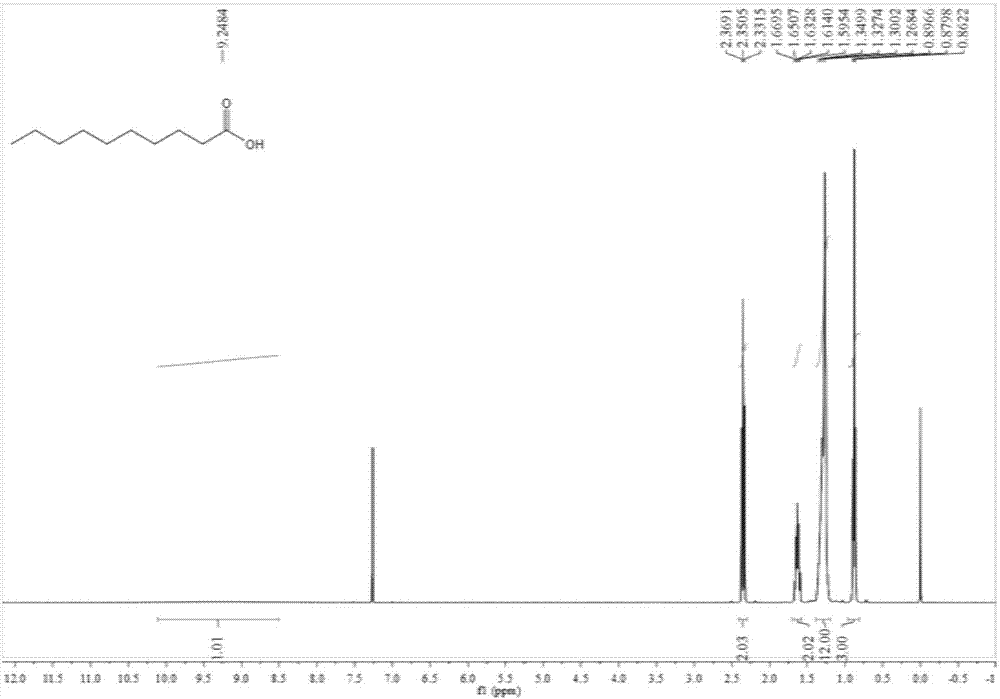

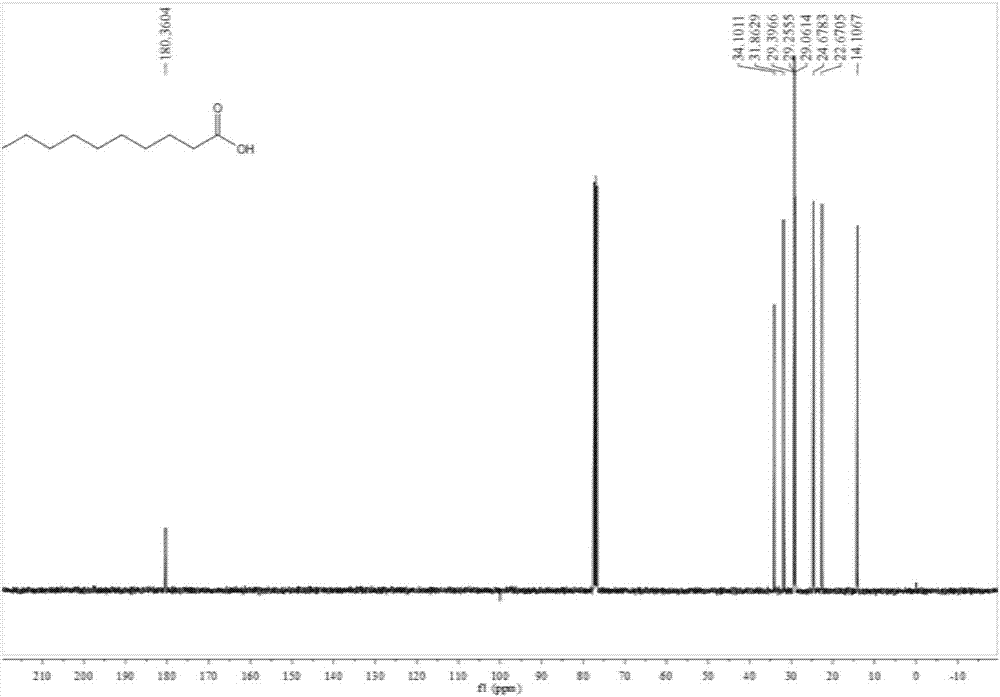

[0065] A preparation method of n-decanoic acid comprises the following steps: hydrodeoxygenating substance A with hydrogen, trifluoromethanesulfonate and a hydrogenation catalyst to obtain n-decanoic acid.

Embodiment 2

[0067] A preparation method of n-decanoic acid, comprising the steps of: combining δ-furfuryl levulinic acid, palladium carbon, W(OTf) 6 , acetic acid, and in a hydrogen atmosphere, adjust the hydrogen pressure to 40atm, stir and heat up to 190°C, keep stirring for 12h, filter the filtrate, and distill under reduced pressure to obtain a solid; dissolve the solid in aqueous sodium hydroxide solution, add activated carbon for decolorization, Filter to get the filtrate, adjust the pH to be less than 2 with hydrochloric acid, filter to get the filter cake, dry to obtain n-decanoic acid, wherein, δ-furfuryl levulinic acid, W(OTf) 6 The molar ratio of palladium element in palladium carbon to δ-furfuryl levulinic acid is 1:200.

Embodiment 3

[0069] A preparation method of n-decanoic acid, comprising the steps of:

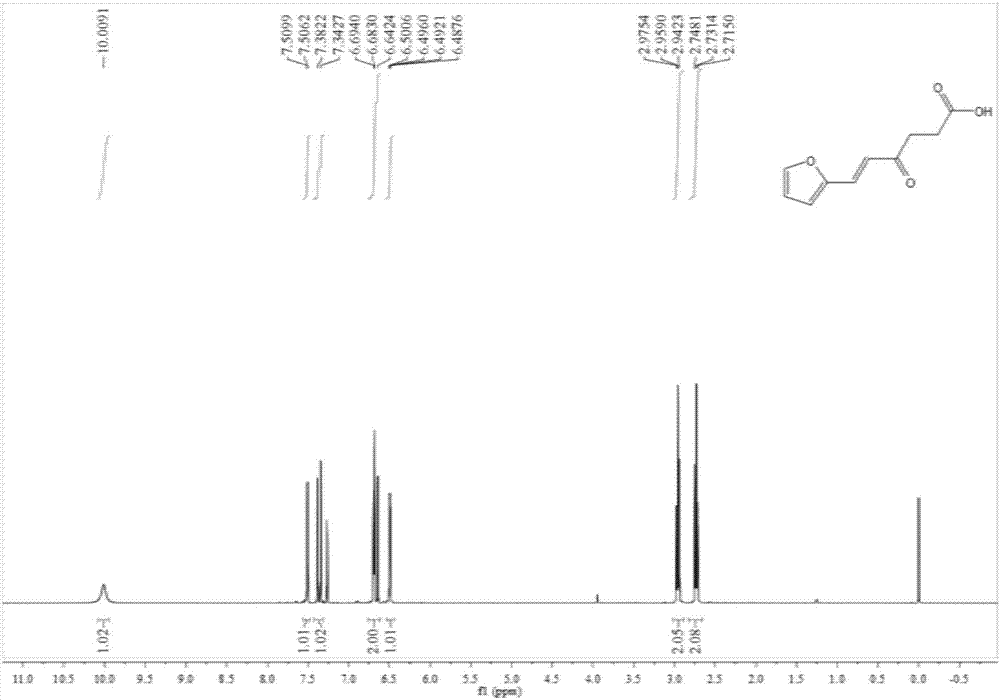

[0070] Mix sodium hydroxide and levulinic acid aqueous solution, heat to reflux, add furfural methanol solution dropwise, reflux and stir for 1 h, acidify with 5wt% hydrochloric acid aqueous solution, filter to take filter cake, wash with ice water, and recrystallize in hot water to obtain δ-furfuryl levulinic acid, wherein the molar ratio of levulinic acid to furfural is 5:3, and the molar ratio of sodium hydroxide to levulinic acid is 1.1:1;

[0071] δ-furfuryllevulinic acid, platinum carbon, Zr(OTf) 4 , acetic acid, and in a hydrogen atmosphere, adjust the hydrogen pressure to 100 atm, stir and heat up to 120 ° C, keep stirring for 48 hours, filter the filtrate, and distill under reduced pressure to obtain a solid; dissolve the solid in aqueous sodium hydroxide solution, add activated carbon for decolorization, Take the filtrate by filtration, adjust the pH to be less than 2 with hydrochloric acid, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com