Titanium sol-containing organosiloxane hybrid emulsion and modified silicate paint

An organosiloxane, inorganic silicate technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc. Affect the appearance of buildings and other problems, achieve obvious hydrophobic performance, obvious photocatalytic performance, good self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

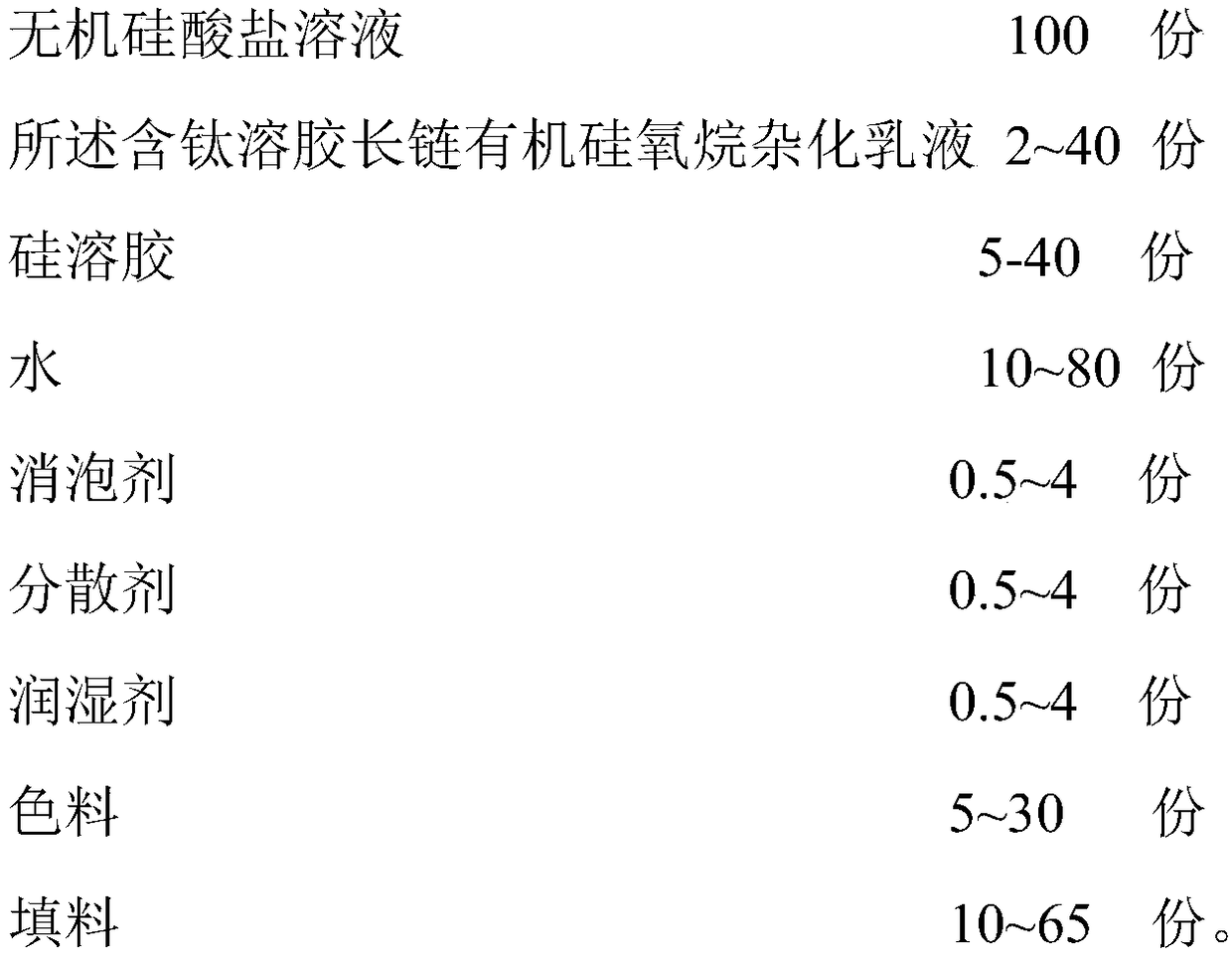

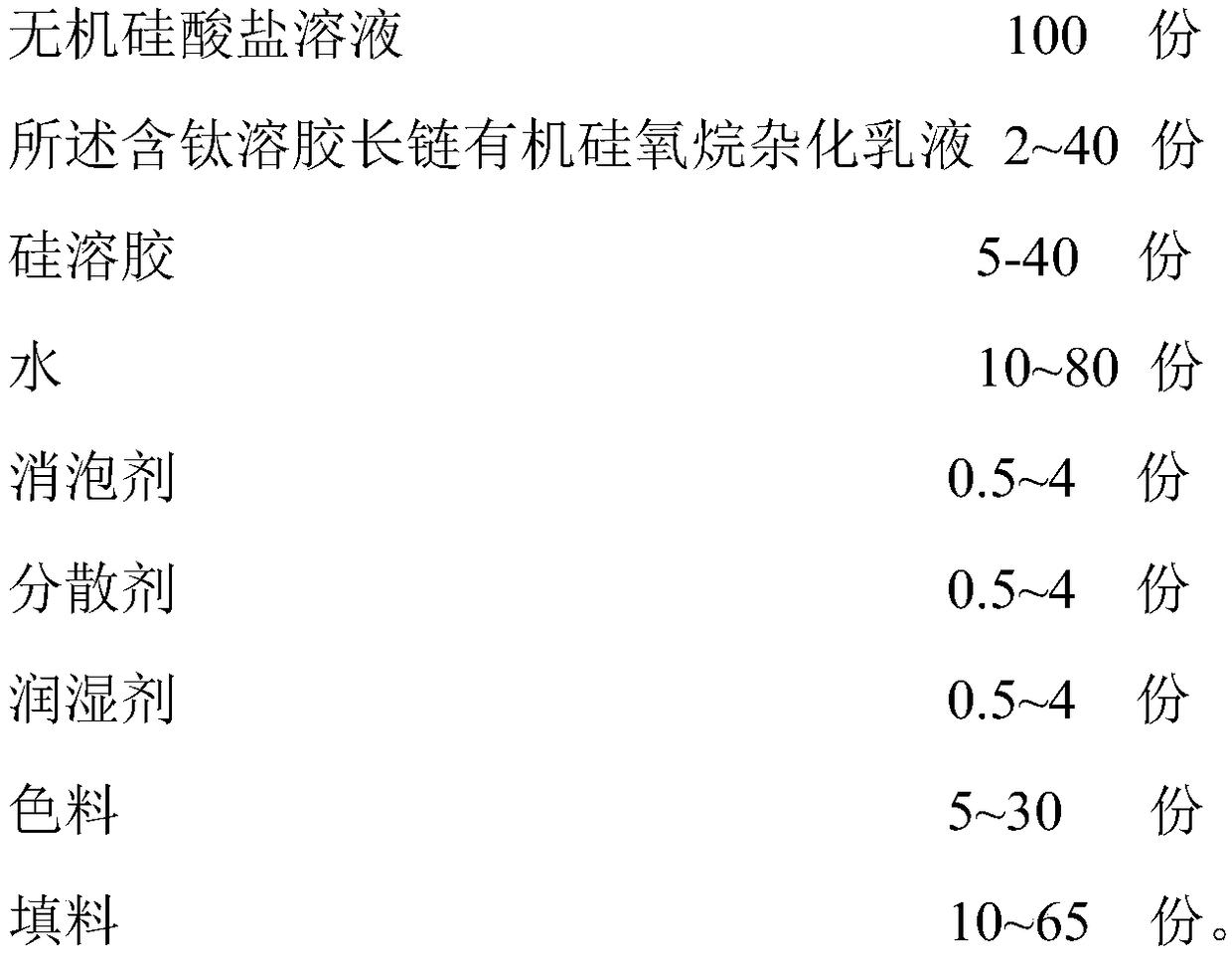

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of a modified inorganic silicate paint, comprising the following steps:

[0037] (1) Preparation of long-chain organosiloxane hybrid emulsion containing titanium sol

[0038] Add 10 parts by weight of tetrabutyl titanate, 60 parts by weight of absolute ethanol, and 5 parts of deionized water into a three-necked flask, heat to 60°C, then add 0.5 parts by weight of hydrochloric acid (mass fraction 37%), at 60°C After reacting for 8 hours, a titanium sol with a solid content of 3% was obtained.

[0039] Add 80 parts by weight of deionized water, 2 parts by weight of dodecylbenzenesulfonic acid, 4 parts by weight of alkylphenol polyoxyethylene ether, 10 parts by weight of the reaction vessel that thermometer, stirrer, condensing pipe and nitrogen are fed into. Parts by weight of octamethylcyclotetrasiloxane were reacted at 70°C for 9 hours to obtain a long-chain organosiloxane emulsion with a solid content of 10%.

[0040] Add 40 parts by weight of ti...

Embodiment 2

[0045] A preparation method of a modified inorganic silicate paint, comprising the following steps:

[0046] (1) Preparation of long-chain organosiloxane hybrid emulsion containing titanium sol

[0047] Add 20 parts by weight of isopropyl titanate, 70 parts by weight of absolute ethanol, and 10 parts by weight of deionized water into a three-necked flask, heat to 50°C, then add 1.5 parts by weight of nitric acid, and react at 50°C for 8 hours to obtain a solid Titanium sol with a content of 5.6%.

[0048] Add 80 parts by weight of deionized water, 3 parts by weight of cetylbenzenesulfonic acid, 6 parts by weight of polyoxyethylene alkyl ether, and 20 parts by weight of Octamethylcyclotetrasiloxane was reacted at 60° C. for 9 hours to obtain a long-chain organosiloxane emulsion with a solid content of 18.3%.

[0049] Add 60 parts by weight of titanium sol with a solid content of 5.6% to 40 parts by weight of long-chain organosiloxane emulsion with a solid content of 18.3%, and ...

Embodiment 3

[0054] A preparation method of a modified inorganic silicate paint, comprising the following steps:

[0055] (1) Preparation of long-chain organosiloxane hybrid emulsion containing titanium sol

[0056] Add 40 parts by weight of isopropyl titanate, 70 parts by weight of absolute ethanol, and 8 parts by weight of deionized water into a three-necked flask, heat it to 55°C, then add 1.5 parts by weight of nitric acid and 0.5 parts by weight of acetic acid, at 40°C The reaction was carried out for 8 hours to obtain a titanium sol with a solid content of 10%.

[0057] Add 80 parts by weight of deionized water, 5 parts by weight of cetylbenzenesulfonic acid, 5 parts by weight of polyoxyethylene sorbitan stearate , 30 parts by weight of octamethylcyclotetrasiloxane were reacted at 70° C. for 9 hours to obtain a long-chain organosiloxane emulsion with a solid content of 25%.

[0058] Add 50 parts by weight of a titanium sol with a solid content of 10% to 50 parts by weight of a long...

PUM

| Property | Measurement | Unit |

|---|---|---|

| alkali resistance | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com