Two-component diatom mud water-based paint free of emission of VOCs

A mud-water-based, two-component technology, used in antifouling/underwater coatings, coatings, and biocide-containing paints, etc., which can solve problems such as unreasonable material matching and reduced performance of diatom mud.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

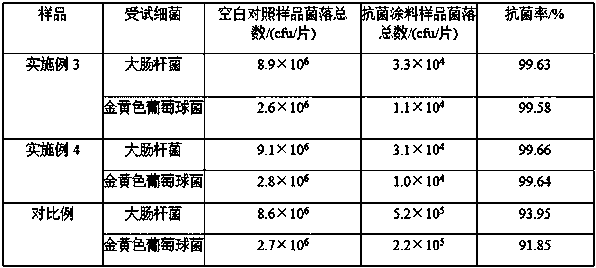

Examples

Embodiment 1

[0025] A kind of far-infrared ceramic powder X is prepared by the following method:

[0026] (1) Preparation of mixture granules: 9 parts of scandium oxide (800 mesh), 5 parts of silicon dioxide (800 mesh), 10 parts of alumina (800 mesh), 14 parts of di Add cerium oxide (800 mesh) and 70 parts of water into the ball milling equipment for ball milling for 6 hours, then add the discharged material, spray and granulate, and obtain granules with a particle size of 20 mesh and a water content of 10%±2%;

[0027] (2) Sintering and crushing: Under the pressure of 30MPa, the medium material (1) was pressed into a plate by dry pressing, and then in a tubular kiln, a weak reducing atmosphere (90% volume fraction of N 2 , 10%H 2 The uniform gas mixture) was calcined at 1500°C for 5 hours, and then cooled to room temperature to obtain a dense plate; the dense plate was crushed, zirconium ball milled for 48 hours, and passed through a 1200-mesh sieve to obtain the far-infrared ceramic pow...

Embodiment 2

[0029] A kind of far-infrared ceramic powder Y is prepared by the following method:

[0030] (1) Preparation of mixed material particles: 6 parts of transition metal oxides, 8 parts of silica (800 mesh), 9 parts of alumina (800 mesh), 11 parts of ceria (800 mesh), 80 parts of water are added to the ball milling equipment and ball milled for 5 hours, then the material is added to the discharge, sprayed and granulated to obtain granules with a particle size of 20 mesh and a water content of 10%±2%;

[0031] (2) Sintering and crushing: Under the pressure of 30MPa, the medium material (1) was pressed into a plate by dry pressing, and then in a tubular kiln, a weak reducing atmosphere (90% volume fraction of N 2 , 10%H 2 The uniform gas mixture) was calcined at 1400°C for 8 hours, and then cooled to room temperature to obtain a dense plate; the dense plate was crushed, zirconium ball milled for 48 hours, and passed through a 1200-mesh sieve to obtain the far-infrared ceramic powde...

Embodiment 3

[0033] A two-component diatom mud water-based coating with zero VOC emission is characterized in that it consists of two components, A and B; in parts by weight, component A is 0.5 parts of potassium persulfate, 30 parts of diatom mud Powder (1200 mesh), 10 parts of rutile titanium dioxide (1200 mesh), 6 parts of far-infrared ceramic powder X (1200 mesh), 60 parts of water, 1.4 parts of polyether modified silicone leveling agent, 0.4 parts of silicone defoaming agent Component B consists of 8 parts of N-hydroxyethylacrylamide, 4 parts of dimethyl diallyl ammonium chloride, 0.3 part of sodium salt of hydroxymethanesulfinic acid, and 5 parts of stearic acid with a mass fraction of 50%. Calcium dispersion, 25 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com