Preparation method of protein-base nanp-particle for dissolving-promoting and synergistic indissolvable bioactive substance

A bioactive substance and nanoparticle technology, which is applied in the field of functional food preparation, can solve the problems of low loading and the use of cross-linking agents, and achieve the effects of increasing loading, low cost and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

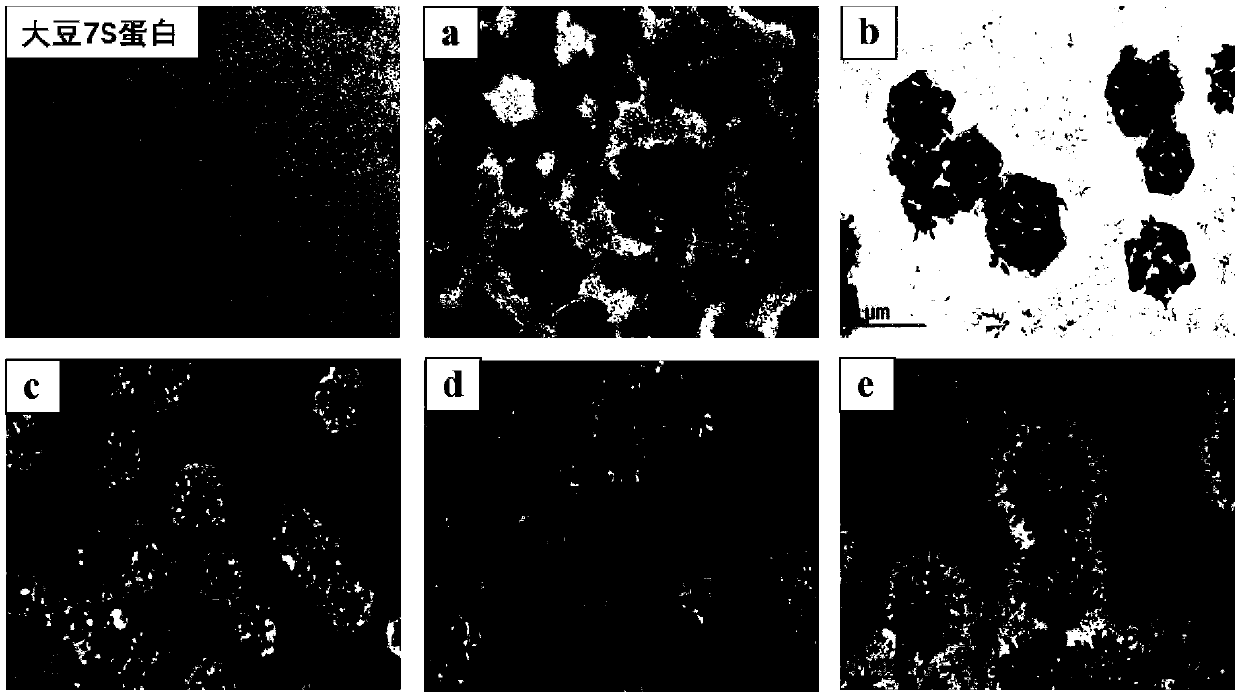

[0034] (1) Accurately weigh 5g of soybean 7S protein powder, disperse it in 100g of distilled water, and continuously stir it at room temperature for 2 hours, then place it in a refrigerator at 4°C for overnight hydration (add 1 drop to the protein solution with a mass concentration of 0.08 % sodium azide, to prevent the growth of microorganisms), to obtain a mass concentration of 5wt% of the original soybean 7S protein stock solution.

[0035] (2) Measure 3mL, 4mL, 5mL, 6mL, 7mL of absolute ethanol in 10mL serum bottles, mark as samples 1, 2, 3, 4, 5, weigh 15mg of curcumin powder and add to 5 samples respectively , and stirred for 1 h in the dark to obtain curcumin ethanol solution.

[0036] (3) Add 5mL, 4mL, 3mL, 2mL, and 1mL deionized water to samples No. 1, 2, 3, 4, and 5 respectively, stir well, and prepare 8 mL of curcumin ethanol / water solutions with different ethanol volume fractions.

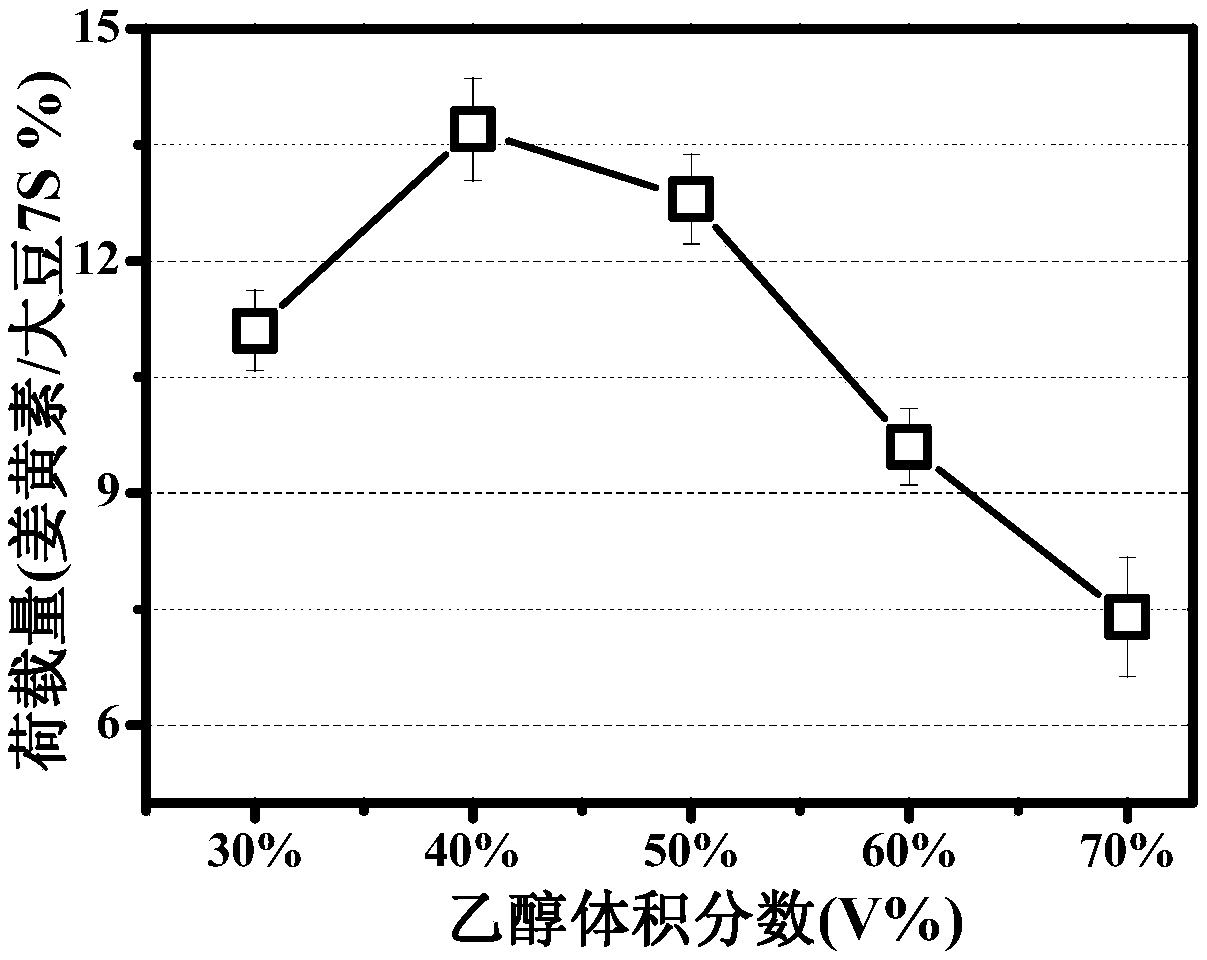

[0037] (4) In the sample of step (3), add 2 mL of original soybean 7S protein sto...

Embodiment 2

[0041] According to the method described in Example 1, a whey protein-curcumin assembly nanoparticle solution was prepared. Except that soybean 7S protein was replaced by whey protein freeze-dried sample, and the protein dispersion was hydrated overnight and then centrifuged (8000g, 20min), other operations were the same as in Example 1. After the whey protein-curcumin assembly particle solution is prepared, take 0.1mL sample in 3mL ethyl acetate, vortex for 60 seconds, let it stand for 30min, take the supernatant according to the ethyl acetate-curcumin standard curve to measure its content Encapsulation efficiency, in the present embodiment, 50% ethanol-treated whey protein has the highest encapsulation efficiency, which can reach 86.3%, that is, 129 mg of curcumin can be buried per gram of whey protein.

Embodiment 3

[0043] According to the method described in Example 1, a bovine serum albumin-curcumin assembly nanoparticle solution was prepared. Except that the soybean 7S protein was replaced with a bovine serum albumin sample, other operations were the same as in Example 1. After the bovine serum albumin-curcumin assembly particle solution is prepared, take a 0.1mL sample to measure its encapsulation efficiency. In this embodiment, the bovine serum albumin treated with 40% ethanol has the highest encapsulation efficiency, which can reach 95.1%. That is, 143 mg of curcumin can be embedded per gram of bovine serum albumin. The reason why bovine serum albumin has such a high encapsulation efficiency is that bovine serum albumin contains a large number of disulfide bonds. Ethanol denatures bovine serum albumin and expands its structure. The sulfur bond is then opened, and when the ethanol is removed by dialysis, in addition to the traction force of the non-covalent bond, there is also the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com