Carbon/hydrotalcite composite adsorption agent, preparation of carbon/hydrotalcite composite adsorption agent, application to heavy metal adsorption and regeneration method

A composite adsorption and hydrotalcite technology, applied in chemical instruments and methods, separation methods, filter regeneration, etc., can solve the problems of poor removal rate, difficult recycling and regeneration, low adsorption capacity, etc., and achieve effective regeneration and recovery, excellent adsorption effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

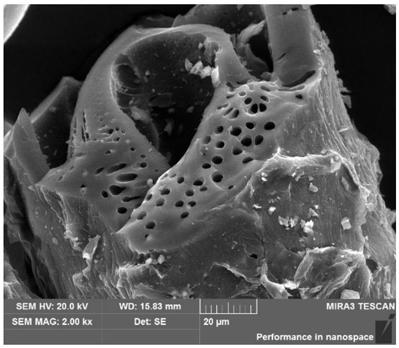

[0082] The camellia husk powder sieved through 120 mesh was dried for later use, and a mixed solution of potassium ferrate and ferric chloride (molar ratio 2:1) with a total mass fraction of 5% was prepared. Take 3g of camellia oleifera husk powder, add 150ml of the prepared mixed solution into a conical flask, and shake for 12h. After 12h, the mixture was filtered and dried at 80°C; then the mixture was burned in a tube furnace at 500°C for 4h. After cooling to room temperature, wash with water repeatedly, and dry to obtain magnetic biochar.

[0083] CO was prepared by hydrothermal method 3 - MgFe hydrotalcite-coated magnetic biochar composite adsorbent. Weigh 0.8g of magnesium chloride and 0.5g of ferric chloride and dissolve in 80ml of water, stir for 10min; add 1g of magnetic biochar, drop in a mixed solution with a total concentration of 0.5mol / L sodium carbonate and sodium hydroxide (molar ratio 1:1) Adjust the pH to 10, then transfer the solution to a polytetrafluoro...

Embodiment 2

[0086] Compared with Example 1, the main difference is that the concentration of potassium ferrate and ferric chloride is 2%, specifically as follows:

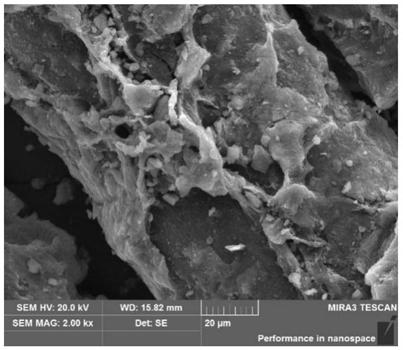

[0087] The camellia husk powder sieved through 120 meshes was dried for later use, and a mixed solution of potassium ferrate and ferric chloride (molar ratio 2:1) with a total mass fraction of 2% was prepared. Take 3g of camellia oleifera husk powder, add 150ml of the prepared mixed solution into a conical flask, and shake for 12h. After 12h, the mixture was filtered and dried at 80°C; then the mixture was burned in a tube furnace at 500°C for 4h. After cooling to room temperature, wash with water repeatedly, and dry to obtain magnetic biochar.

[0088] CO was prepared by hydrothermal method 3 - MgFe hydrotalcite-coated magnetic biochar composite adsorbent. Weigh 0.8g of magnesium chloride and 0.5g of ferric chloride and dissolve in 80ml of water, stir for 10min; add 1g of magnetic biochar, drop in a mixed solution with a t...

Embodiment 3

[0091]Compared with Example 1, the main difference is that the mol ratio of potassium ferrate to ferric chloride is 1:1, specifically as follows:

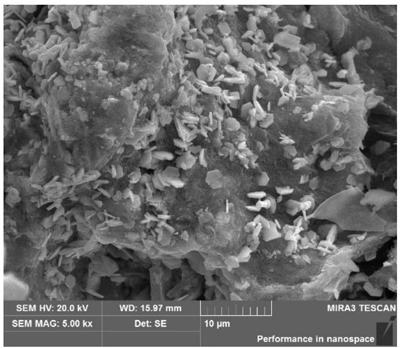

[0092] The camellia husk powder sieved through 120 meshes was dried for later use, and a mixed solution of potassium ferrate and ferric chloride (molar ratio 1:1) with a total mass fraction of 5% was prepared. Take 3g of camellia oleifera husk powder, add 150ml of the prepared mixed solution into a conical flask, and shake for 12h. After 12h, the mixture was filtered and dried at 80°C; then the mixture was burned in a tube furnace at 500°C for 4h. After cooling to room temperature, wash with water repeatedly, and dry to obtain magnetic biochar.

[0093] CO was prepared by hydrothermal method 3 - MgFe hydrotalcite-coated magnetic biochar composite adsorbent. Weigh 0.8g of magnesium chloride and 0.5g of ferric chloride and dissolve in 80ml of water, stir for 10min; add 1g of magnetic biochar, drop in a mixed solution with a total ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com